Method of preparing nano-crystal titanium oxide colloid used for optoelectronic cell

A technology of nanocrystals and photovoltaic cells, applied in the field of nanomaterials, can solve the problems of incomplete crystallization, instability, and easy stratification of nano-TiO sol, and achieve the effects of rapid response, improved conversion efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

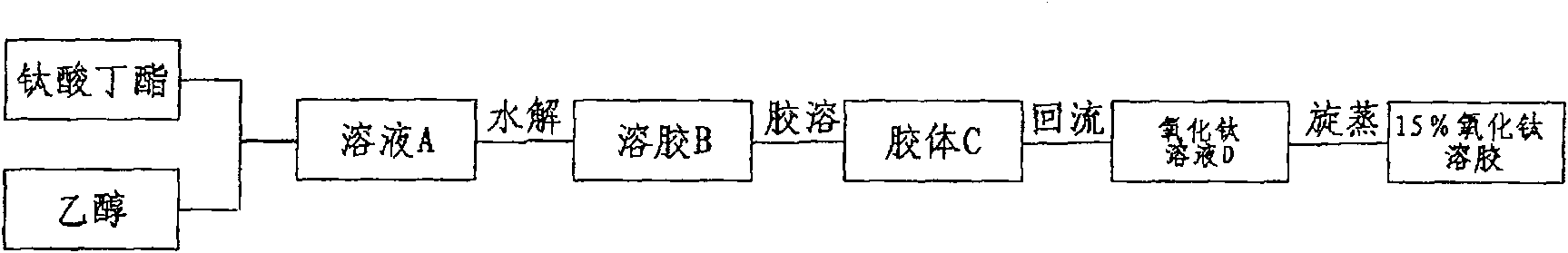

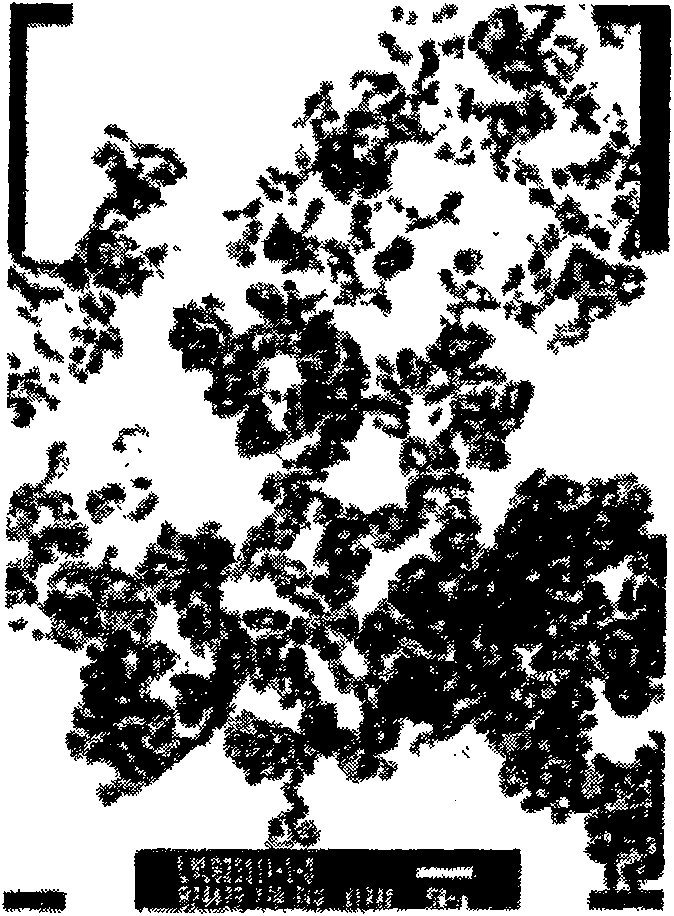

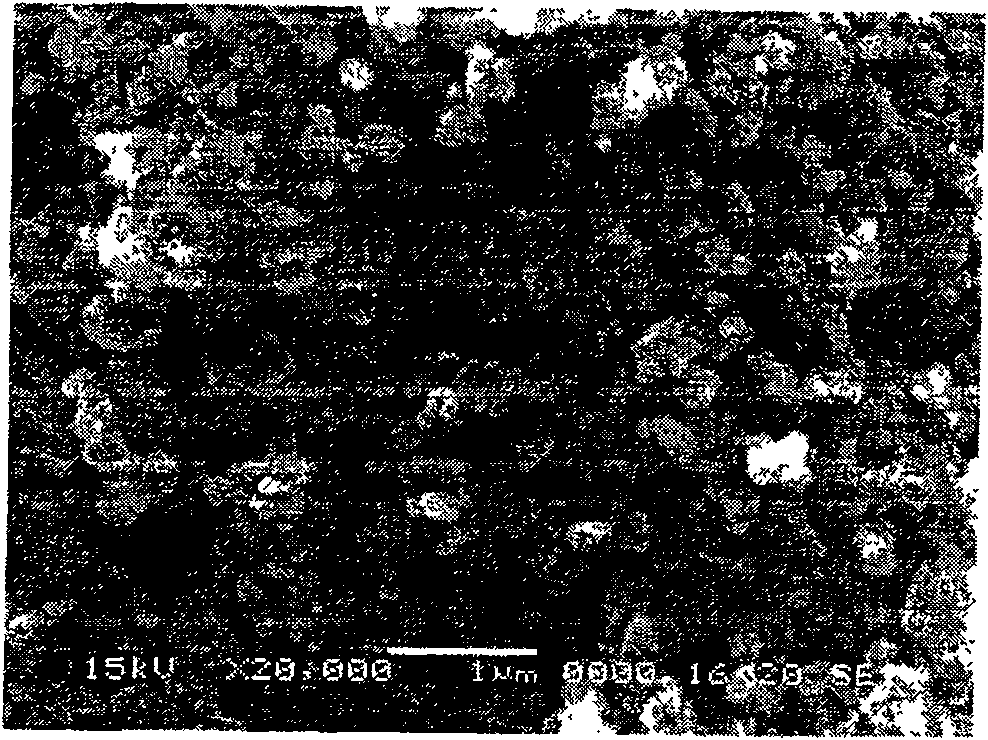

[0031] First prepare solution A: add 100 mL of butyl titanate to 200 mL of ethanol solution, then add 20 mL of diethanolamine as a stabilizer, and stir vigorously to obtain a light yellow transparent solution. Slowly add 25mL of pure water dropwise into solution A while vigorously stirring to form transparent sol B. Put sol B at a constant temperature of 25°C for 24 hours to obtain uniform TiO 2 Colloid C. TiO 2 Colloid C was refluxed at 150 ° C for 5 h to evaporate to remove residual organic matter, and to obtain nanocrystalline TiO with a mass concentration of about 1%. 2 Solution D. Finally, the solution D was rotary vacuum evaporated for 2h to obtain nanocrystalline TiO with a mass concentration of 15%. 2 colloid. figure 2 TiO prepared for this example 2 Spherical TiO can be seen in the TEM photo of the colloid after drying 2 Particles, the particle size of which is less than 10nm. image 3 TiO 2 SEM photo of the colloidal coating, nano-TiO can be found 2 The thin...

Embodiment 2

[0033] First prepare solution A: add 150 mL of butyl titanate to 300 mL of ethanol solution, then add 30 mL of diethanolamine as a stabilizer, stir vigorously to obtain a light yellow transparent solution. Slowly add 37.5mL of pure water dropwise into solution A while vigorously stirring to form transparent sol B. Put sol B at a constant temperature of 25°C for 24 hours to obtain uniform TiO 2 Colloid C. TiO 2 Colloid C was refluxed at 100°C for 2h and evaporated to remove residual organic matter to obtain TiO with a mass concentration of about 1%. 2 Solution D. Add dilute hydrochloric acid to adjust TiO 2 The pH value of the solution was 9-11, and then the solution D was evaporated in a rotary vacuum for 2 hours to obtain nanocrystalline TiO with a mass concentration of 15%. 2 colloid. Description of the prepared nanocrystalline TiO 2 The colloid can adjust different pH values, and it can still maintain uniformity and stability in a weakly acidic environment.

Embodiment 3

[0035] First prepare solution A: add 100 mL of butyl titanate to 200 mL of ethanol solution, then add 20 mL of acrylamide as a stabilizer, stir vigorously to obtain a light yellow transparent solution. Slowly add 25mL of pure water dropwise into solution A while vigorously stirring to form transparent sol B. Put sol B at a constant temperature of 25°C for 24 hours to obtain uniform TiO 2 Colloid C. TiO 2 Colloid C was refluxed at 100°C for 2h and evaporated to remove residual organic matter to obtain TiO with a mass concentration of about 1%. 2 solution. Figure 6 TiO prepared for this example 2 From the XRD spectrum of the sample, it can be seen that the crystallization of titanium oxide is not complete, and there are only a few anatase phase components, indicating that strict control of the reflow temperature and time of the colloid is very important for the crystallization of the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com