A method for charging battery

A battery charging and battery technology, applied in the direction of secondary battery charging/discharging, battery circuit device, secondary battery repair/maintenance, etc., can solve the problems of inconvenience, complex circuit composition, and high requirements for battery cell protection IC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For making the purpose of the present invention, method feature and effect thereof, do further understanding and understanding, give embodiment to coordinate drawing, describe in detail as follows:

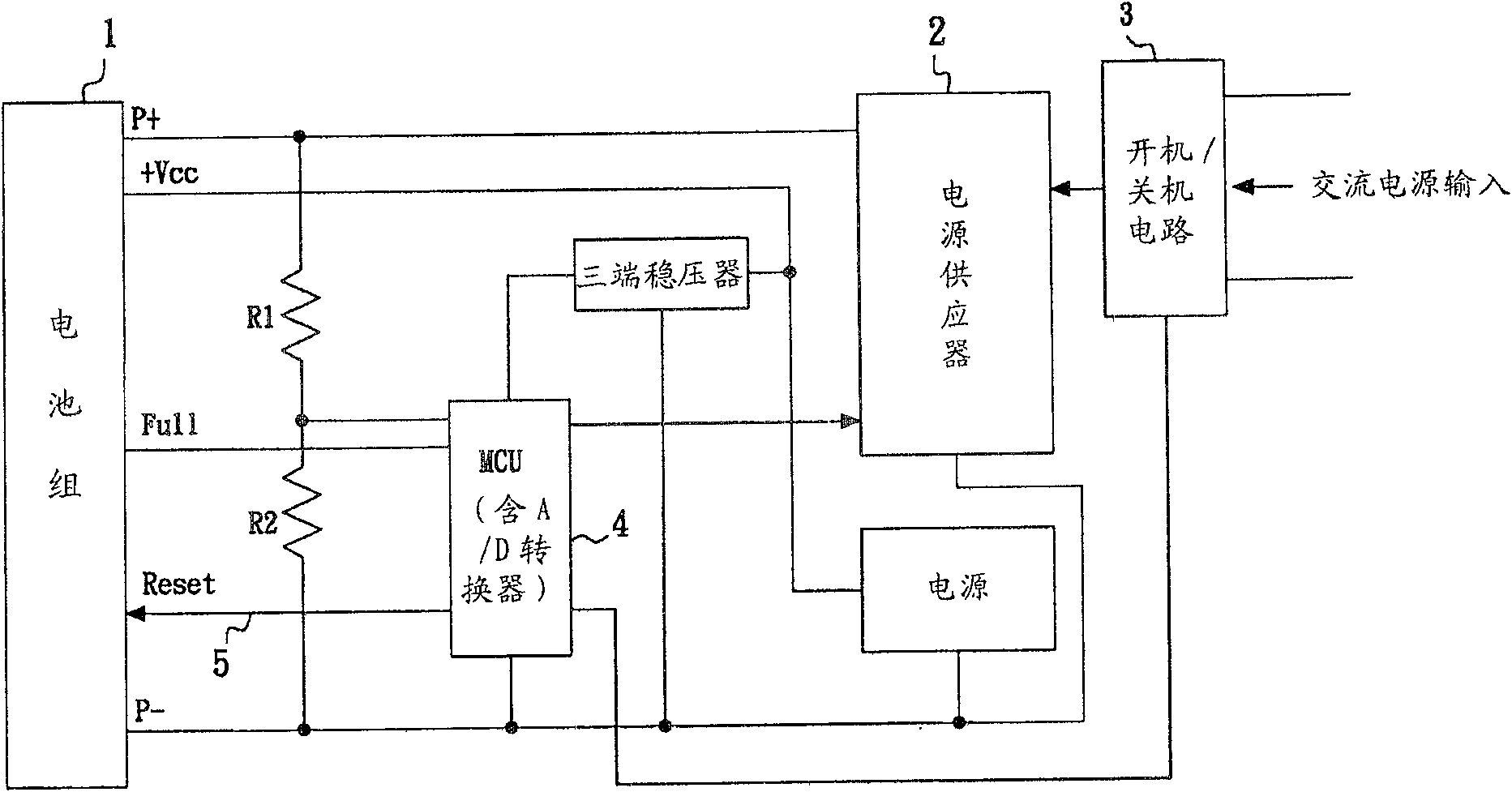

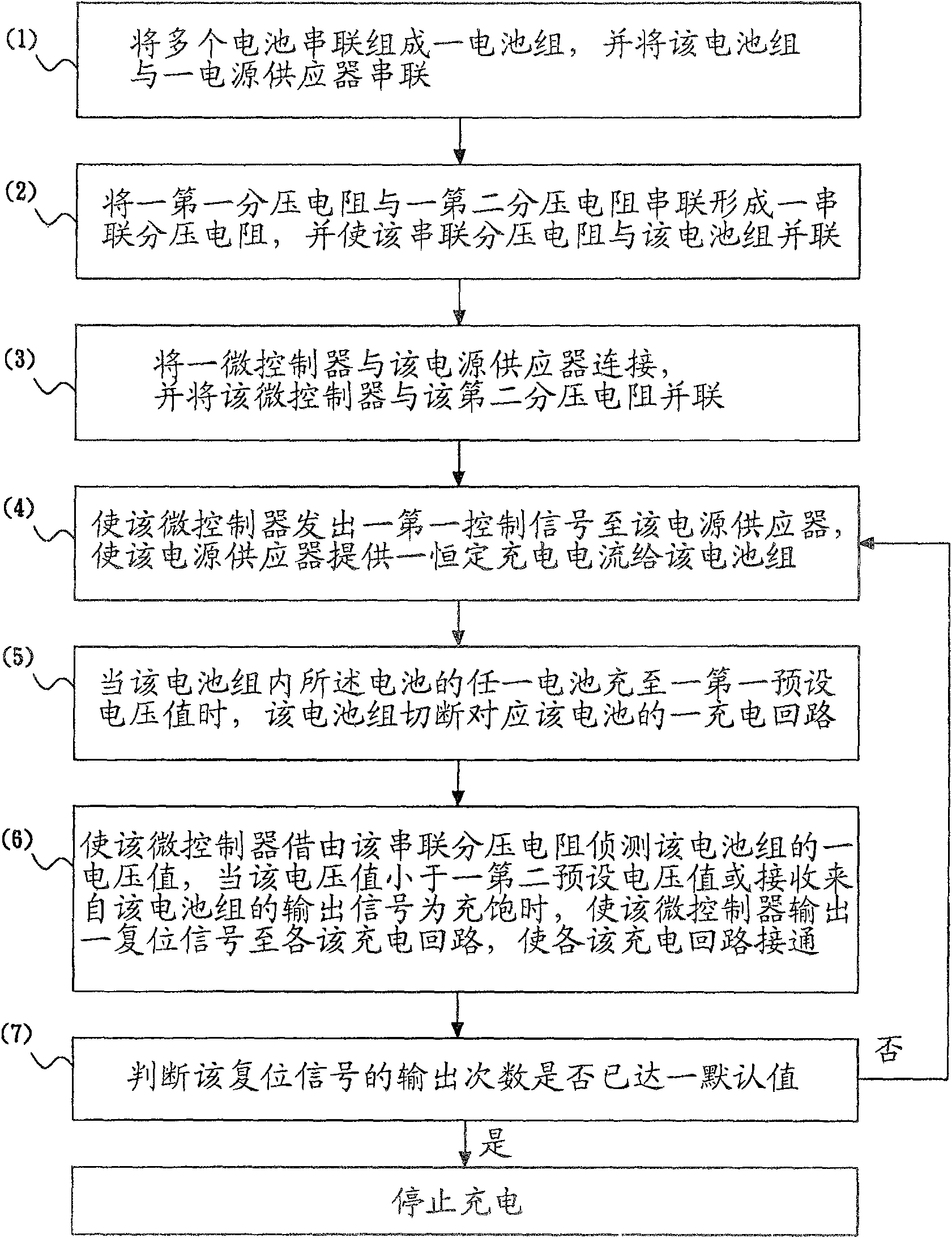

[0030] figure 1 It is a schematic diagram of a preferred specific embodiment of the method according to the present invention. As shown in the figure, firstly connect a plurality of batteries in series to form a battery pack 1, and connect the battery pack 1 with a power supply 2 (for example: step-by-step variable charger or a linear variable charger, but not limited to) in series, wherein each battery can be a high capacity capacitor or a lithium battery. In addition, a first voltage dividing resistor R1 and a second voltage dividing resistor R2 are connected in series to form a series voltage dividing resistor, and the series voltage dividing resistor is connected in parallel with the battery pack 1 . Then a microcontroller 4 comprising an analog / digital converter (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com