Vertical type gripper for kelp seedling

A seedling clipping machine and vertical technology, applied in the field of vertical kelp seedling clipping machine, can solve the problems of low stability of the mechanism, insufficient reliability, poor practicability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

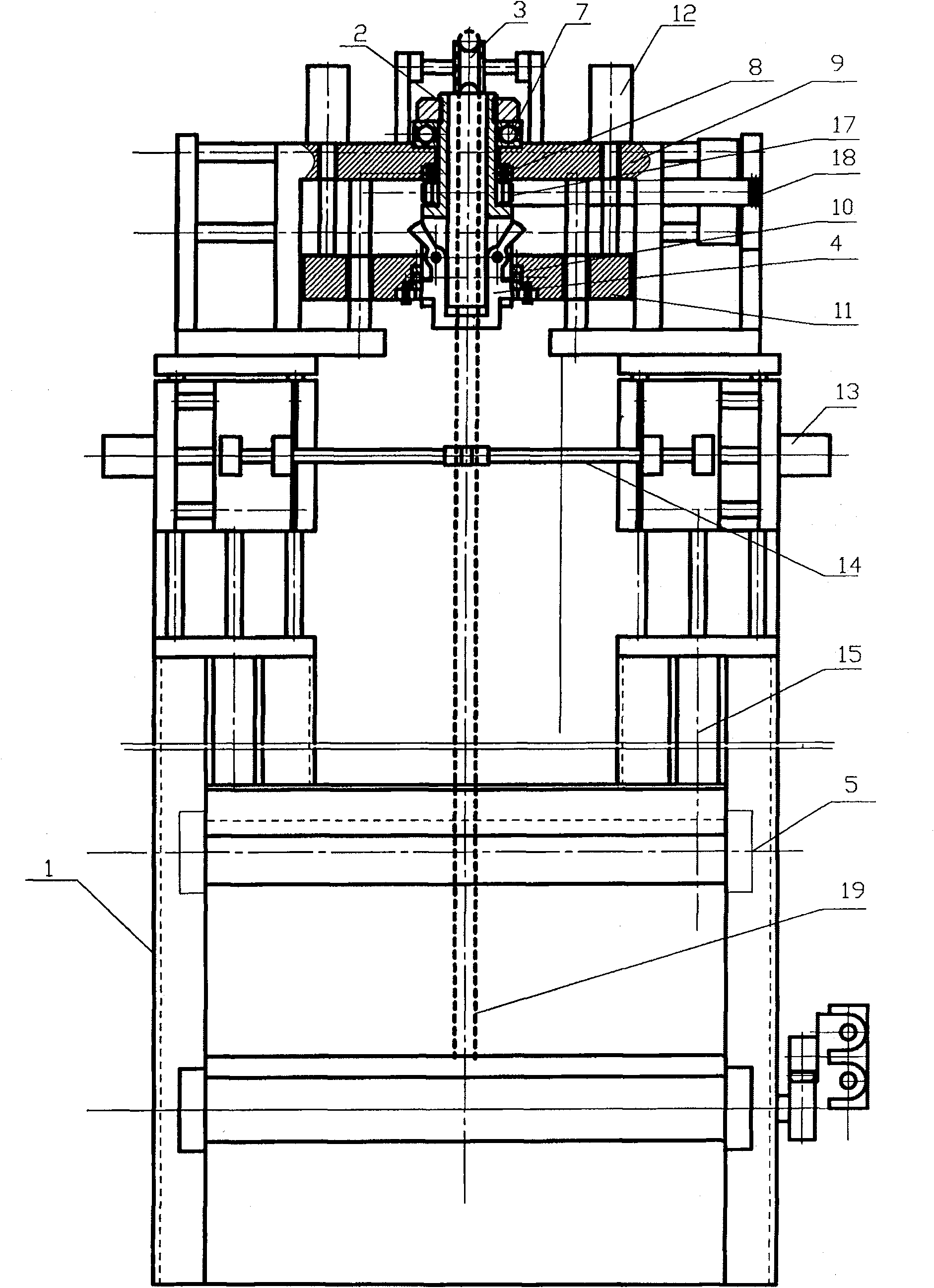

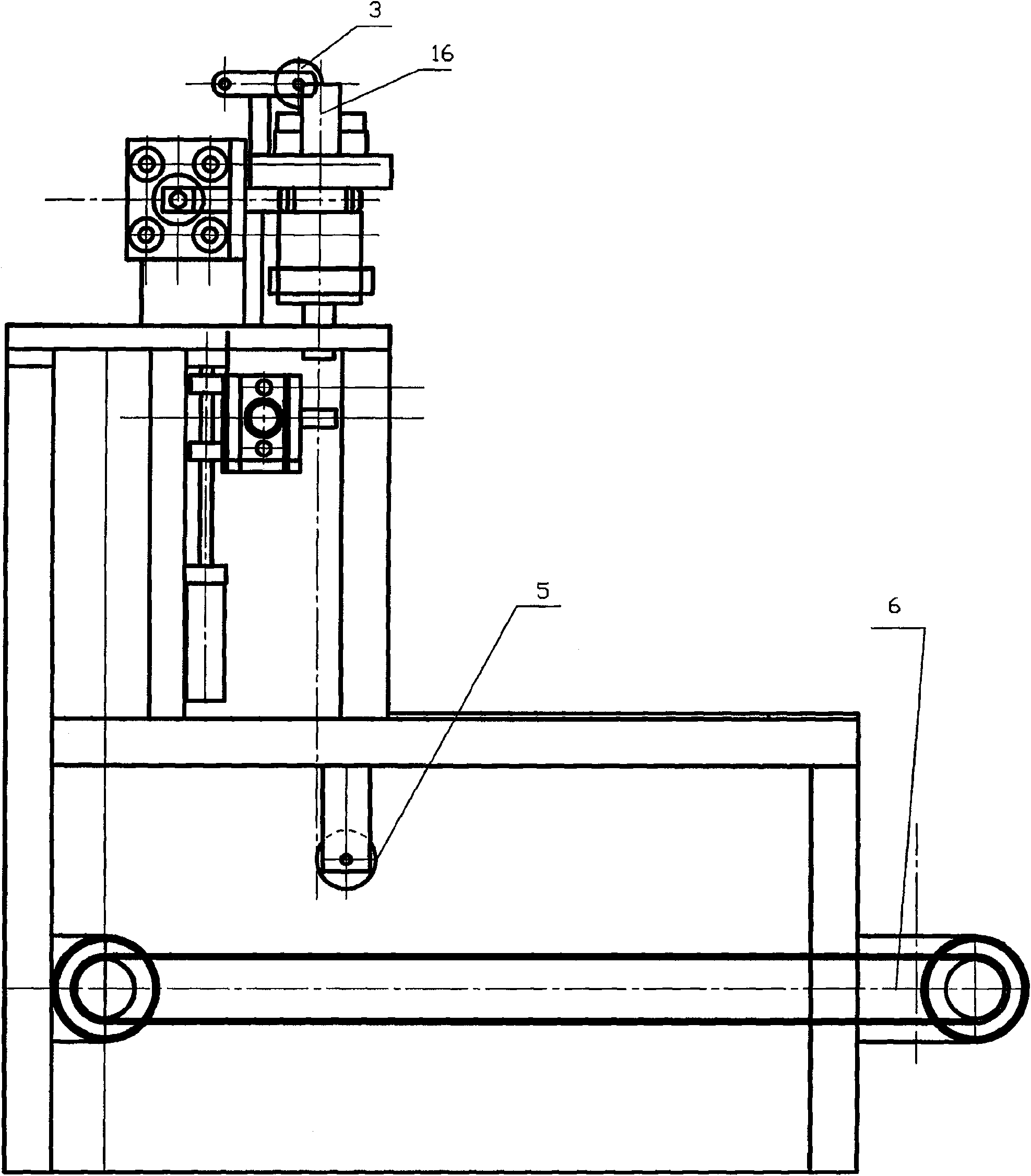

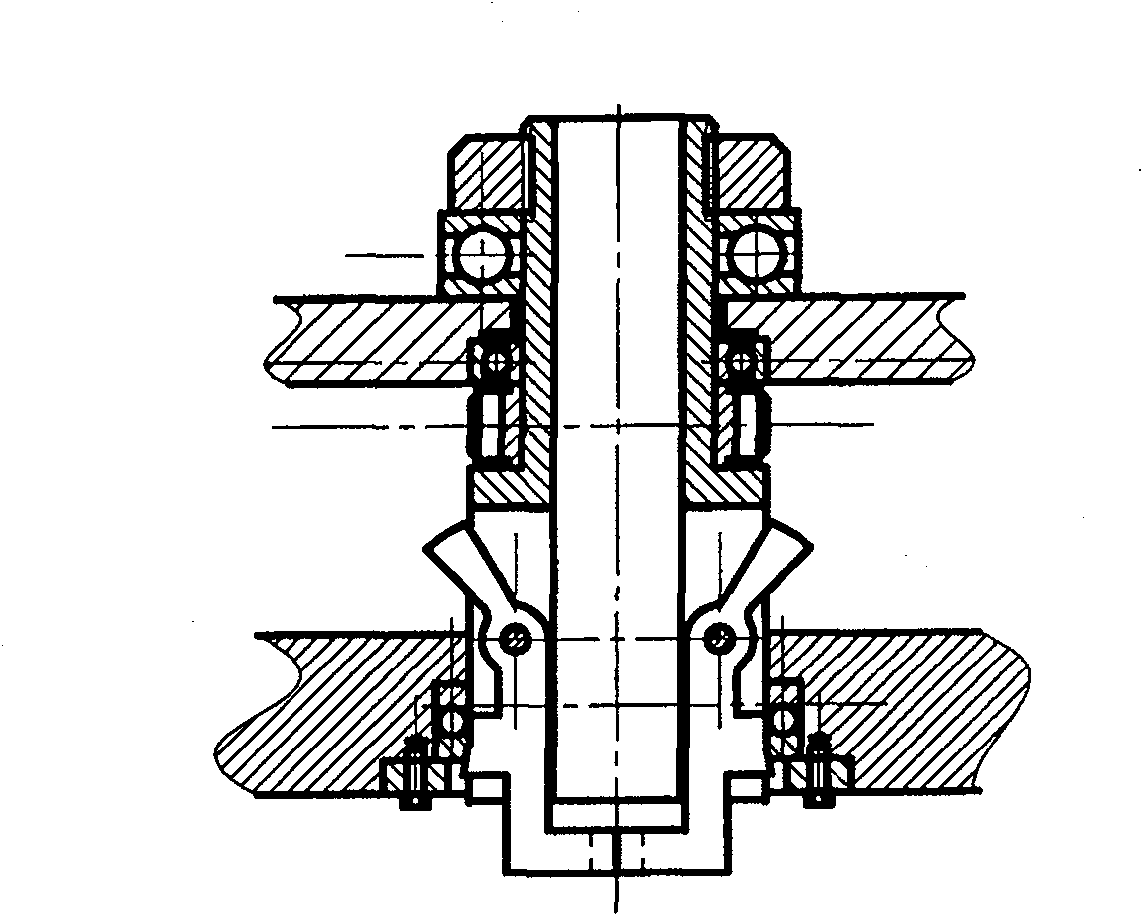

[0036] Now in conjunction with accompanying drawing, the present invention will be further described:

[0037] like figure 1 , figure 2 Shown vertical kelp clamping machine comprises frame 1, axle body 2, ball bearing 8, thrust bearing I and II, gear 17, rack 18, rotary cylinder 16, two upper compression cylinders 12, two Press down cylinder 13, claw 4, hold down bar 14, two walking cylinders 15, transmission device 6, described axle body 2, claw 4, bearing, gear 17, press down cylinder 12,13 and press The tight rod 14 and the travel cylinder 15 are all arranged symmetrically with the central axis of the shaft body.

[0038] The movable guide wheel 3 is twisted to an angle, and the seedling rope 19 is a polyethylene fiber random silk blended rope, which is composed of three strands, with a diameter of about 16mm, and is suitable for tightness. Pierce through the inner hole, and the lower end is a rolling wheel 5 to keep the plumb state;

[0039] The shaft body 2 is suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com