Power module, manufacturing method therefor, and air conditioner

A power module, non-power technology, applied in the field of air conditioners equipped with power modules, can solve the problems of high cost, increased personnel costs and equipment costs, and rising power module costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070]

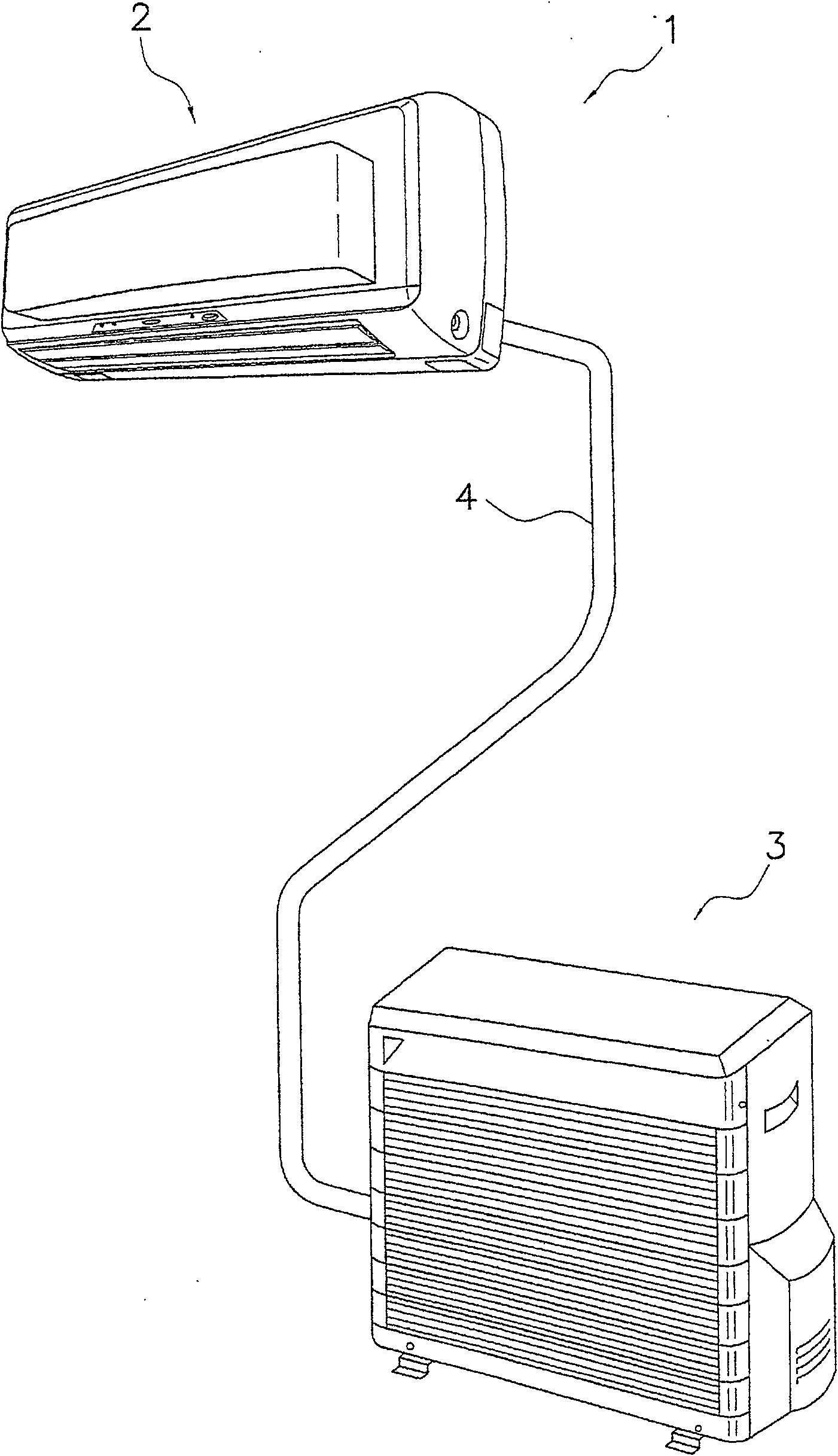

[0071] figure 1 It is an external perspective view showing the air conditioner 1 of this embodiment.

[0072] This air conditioner 1 includes: a wall-mounted indoor unit 2 mounted on a wall or the like indoors; and an outdoor unit 3 installed outdoors.

[0073] An indoor heat exchanger is housed in the indoor unit 2, and an outdoor heat exchanger is housed in the outdoor unit 3, and the heat exchangers are connected together by a refrigerant pipe 4 to constitute a refrigerant circuit.

[0074]

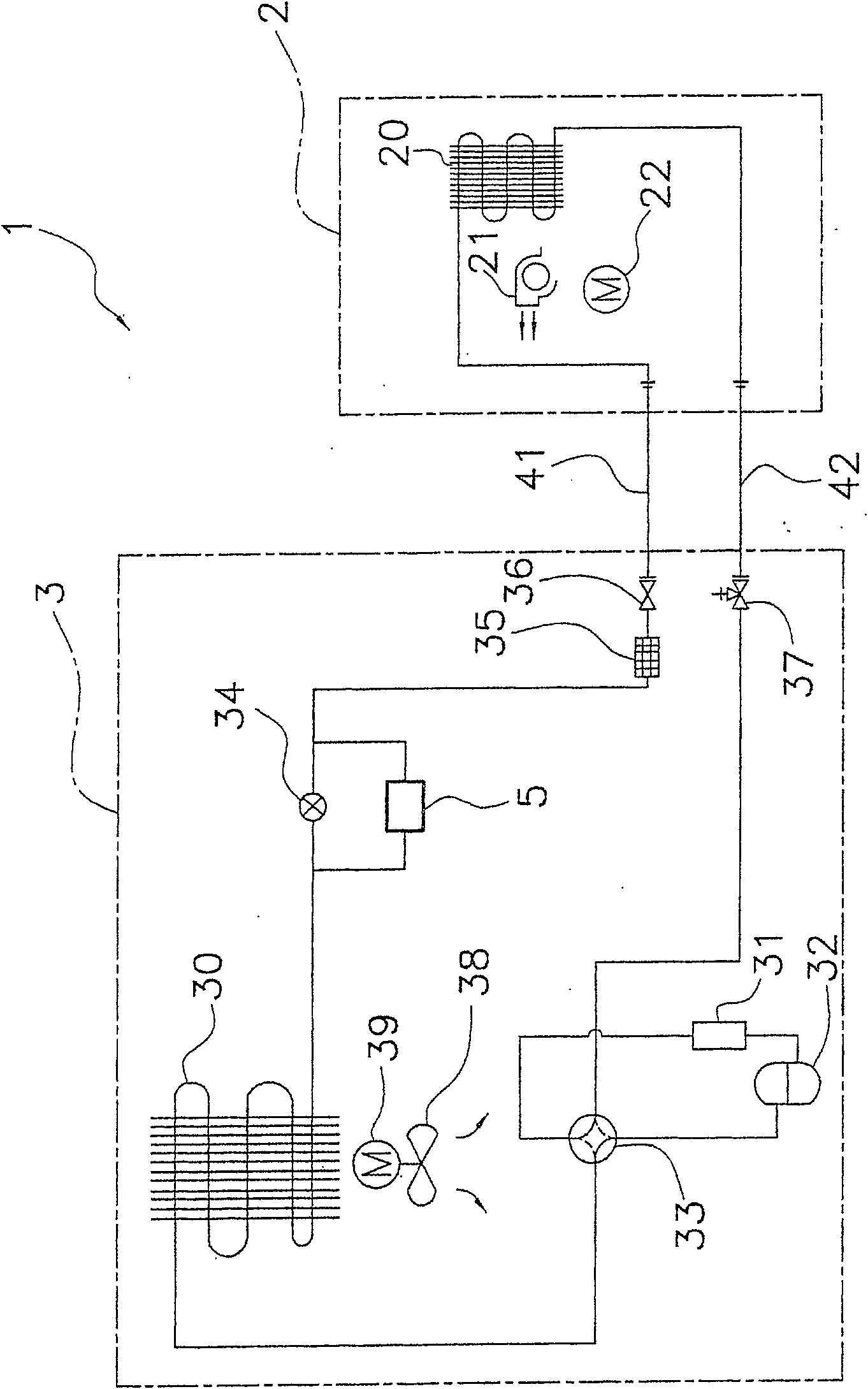

[0075] figure 2 The structure of the refrigerant circuit of the air conditioner 1 is shown. The refrigerant circuit is mainly composed of an indoor heat exchanger 20 , an accumulator (accumulator) 31 , a compressor 32 , a four-way switching valve 33 , an outdoor heat exchanger 30 and an electric expansion valve 34 .

[0076] The indoor heat exchanger 20 provided in the indoor unit 2 performs heat exchange with the air in contact with it. In addition, the indoor unit 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com