Sign point hole filling method based on neural network in tri-D scanning point cloud

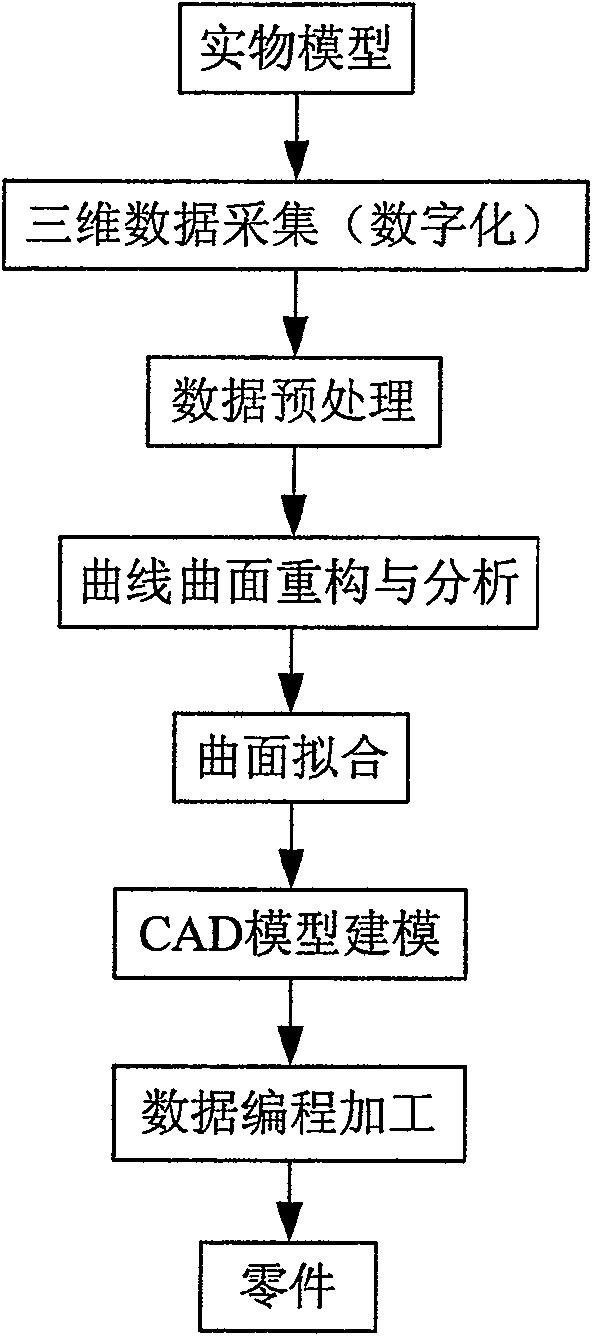

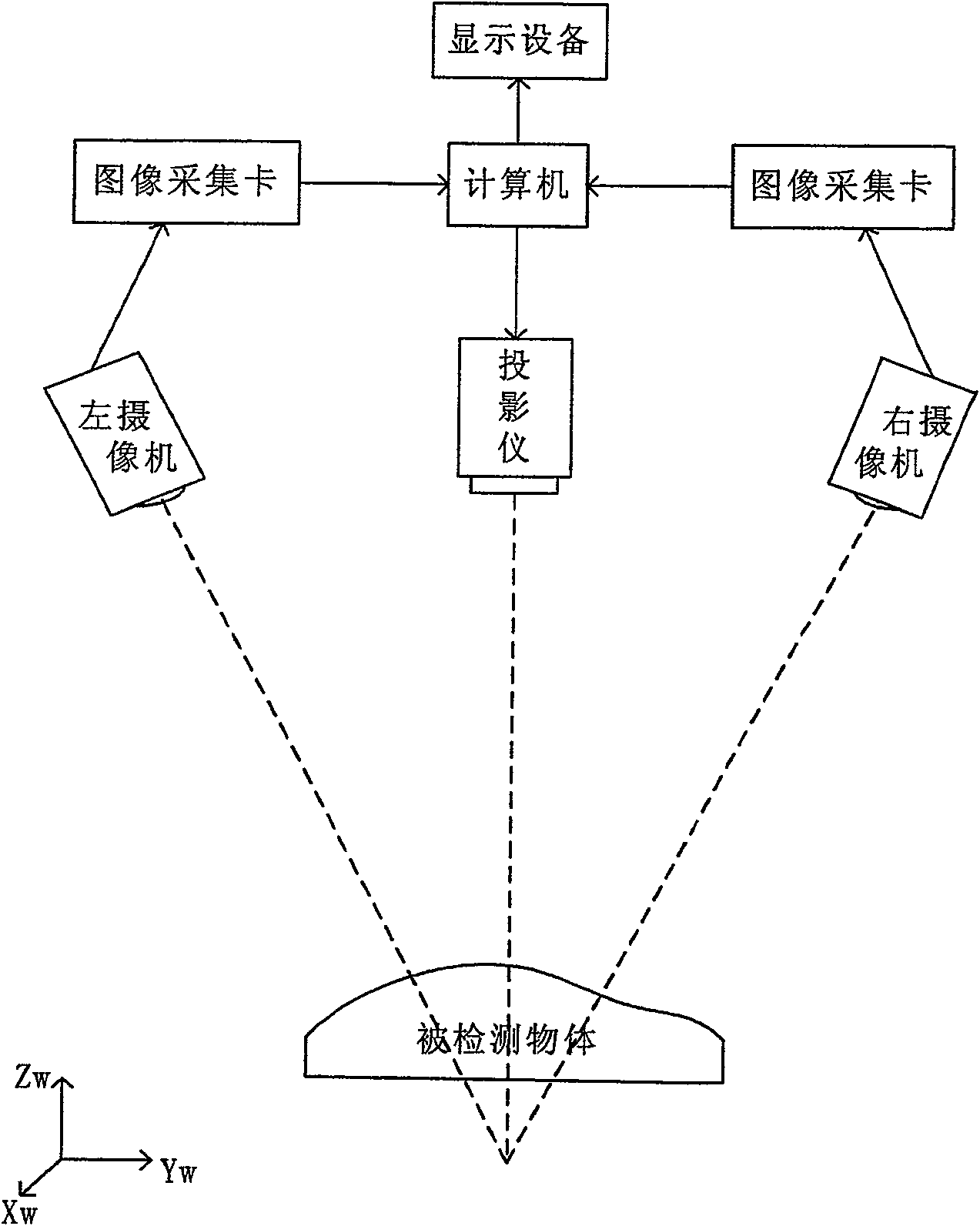

A technology of 3D scanning and neural network, which is applied to the field of filling holes in 3D scanning point clouds based on neural networks. , The point cloud features are well represented and the speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

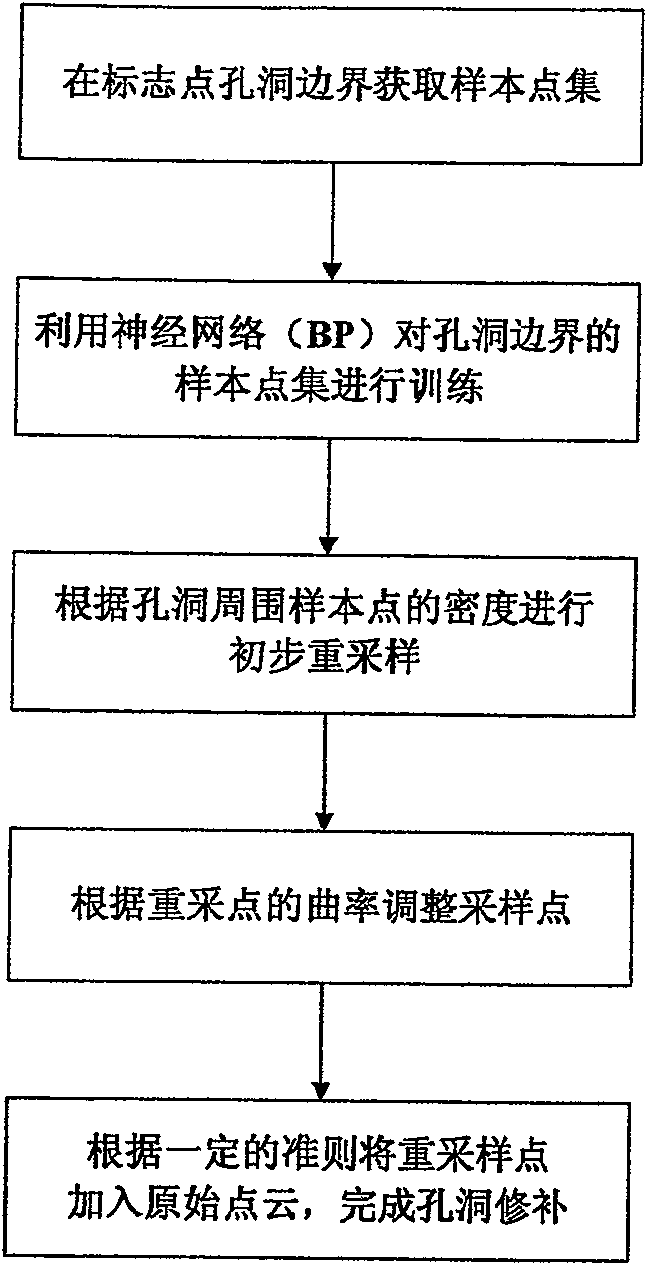

[0035] A point cloud hole filling method for 3D scanning based on neural network:

[0036] Step 1: For the hole formed by the marker points pasted on the surface of the head of Venus, in the 3D scanning point cloud, when obtaining the sample point set around the hole, according to the 3D coordinates of the marker points (x b ,y b ,z b ), take the data points in the cube centered on the marker point as the sample point P for hole filling s (s=0,1,...,t), t is the number of sample points, and the 8 vertices of the cube are (x b -r,y b -r,z b -r), (x b -r,y b -r,z b +r), (x b -r,y b + r, z b -r), (x b -r,y b + r, z b +r), (x b +r,y b -r,z b -r), (x b +r,y b -r,z b +r), (x b +r,y b + r, z b -r), (x b +r,y b + r, z b +r), where r is the selected domain value, in order to obtain a suitable sample point set, take 1.2 to 1.5 times the radius of the marker point;

[0037] Step 2: According to the sample point data P s , training the neural network for filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com