Power supply control method and power supply device for electron beam generating system of electron beam bombardment furnace

A technology of electron beam bombardment and generation system, which is applied in the direction of electric heating devices, electrical components, heating through discharge, etc., can solve the problems of reduced operating efficiency, increased difficulty of filtering, and reduced operating efficiency, so as to reduce harmonic components and reduce manufacturing Cost, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiment of the power control method of the electron beam generating system of the electron beam bombardment furnace of the present invention is as follows:

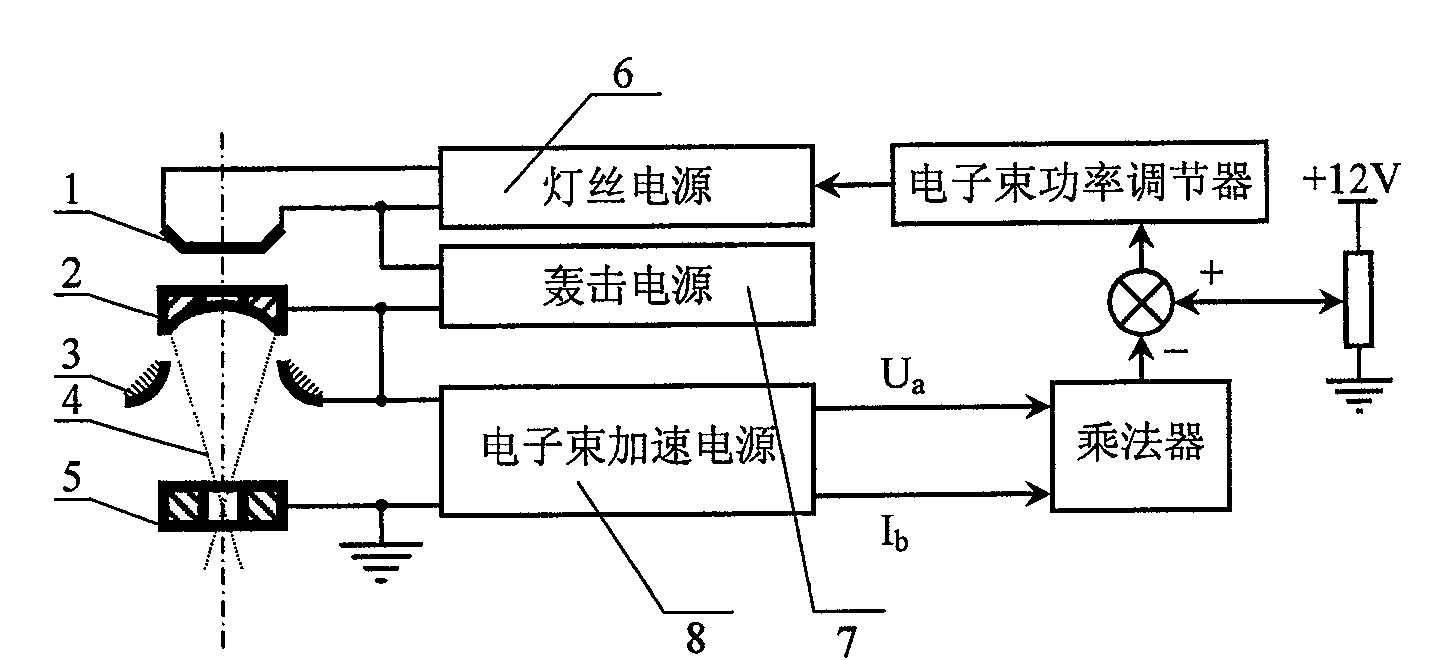

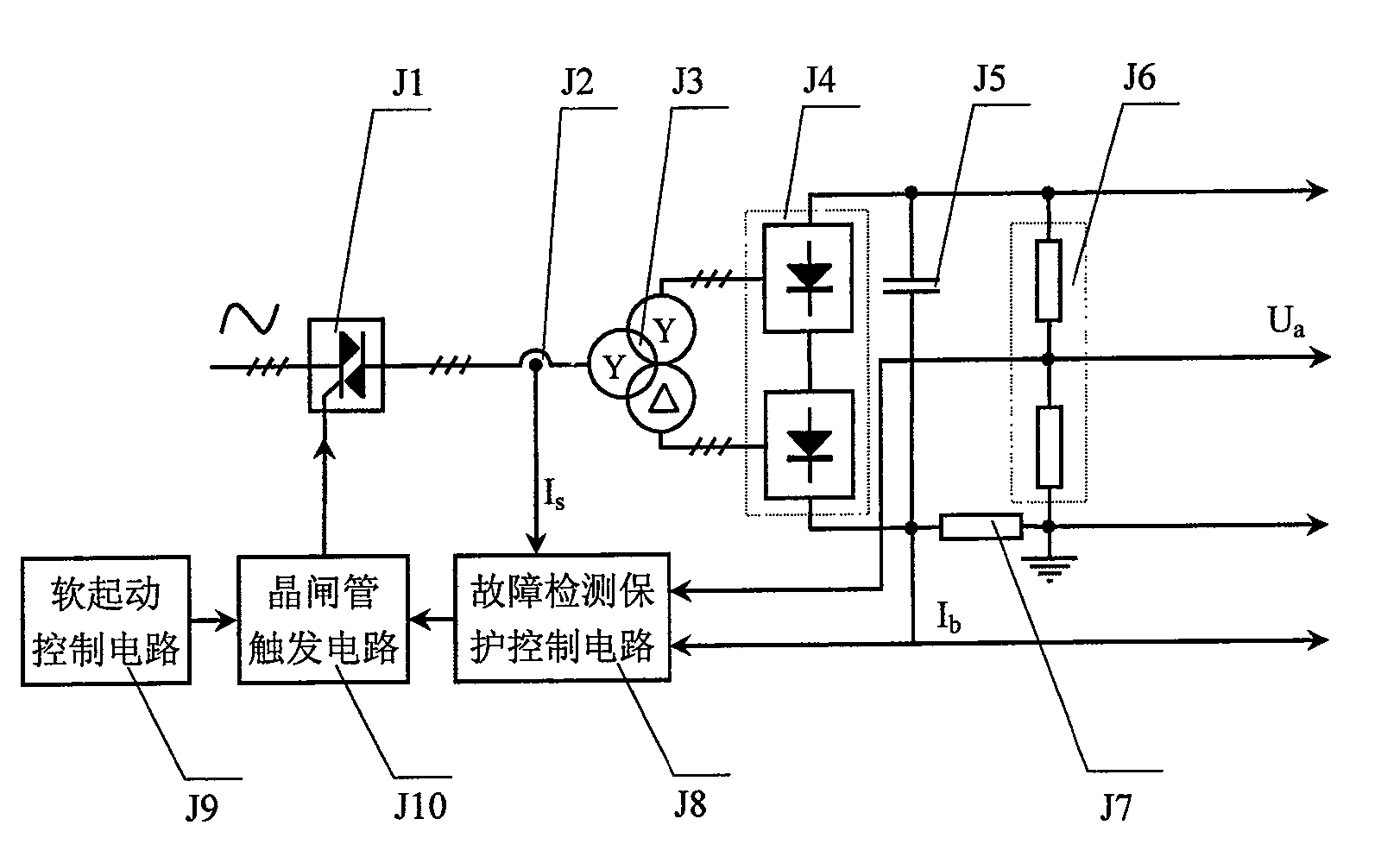

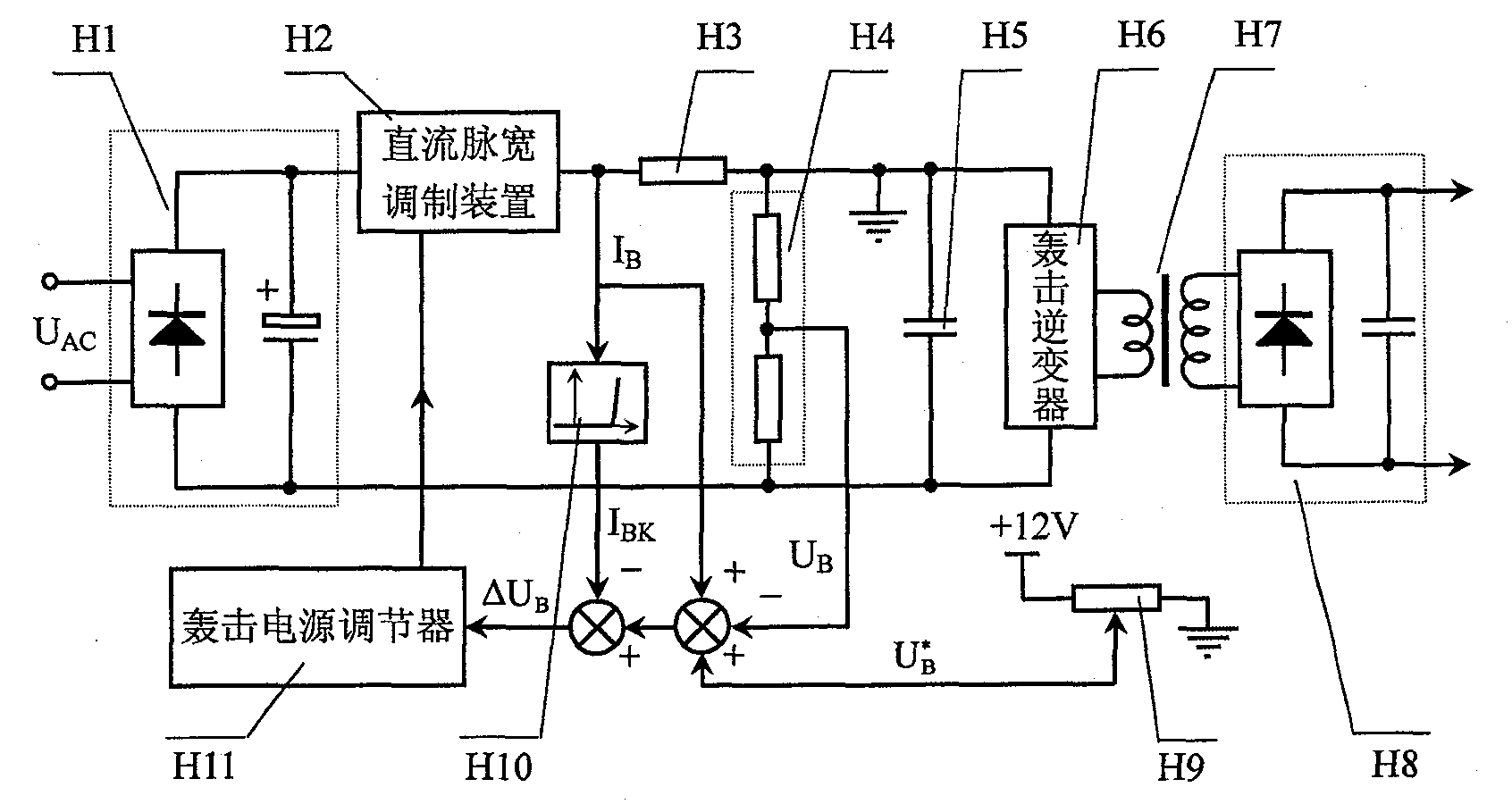

[0044] The electron beam acceleration power supply adopts thyristor soft start and soft stop to realize the gentle rise and fall of the acceleration voltage during the start-stop process; the acceleration power supply in the smelting process adopts open-loop control, and the input terminal of the step-up main transformer is directly connected to the three-phase mains, and the input voltage is a complete three-phase Phase sine wave, uncontrollable DC high voltage is obtained by six-phase twelve-pulse full-wave rectification after boosting, and the input current waveform of the booster main transformer is an approximate sine wave; the DC high voltage output terminal is connected with a sampling circuit, which outputs acceleration voltage samples respectively Signal U a and electron beam sampling signal I b . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com