Method for piezoelectric vibrator

A piezoelectric vibrator and vibrator technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive transducers, piezoelectric devices/electrostrictive devices, etc., can solve performance problems damage, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

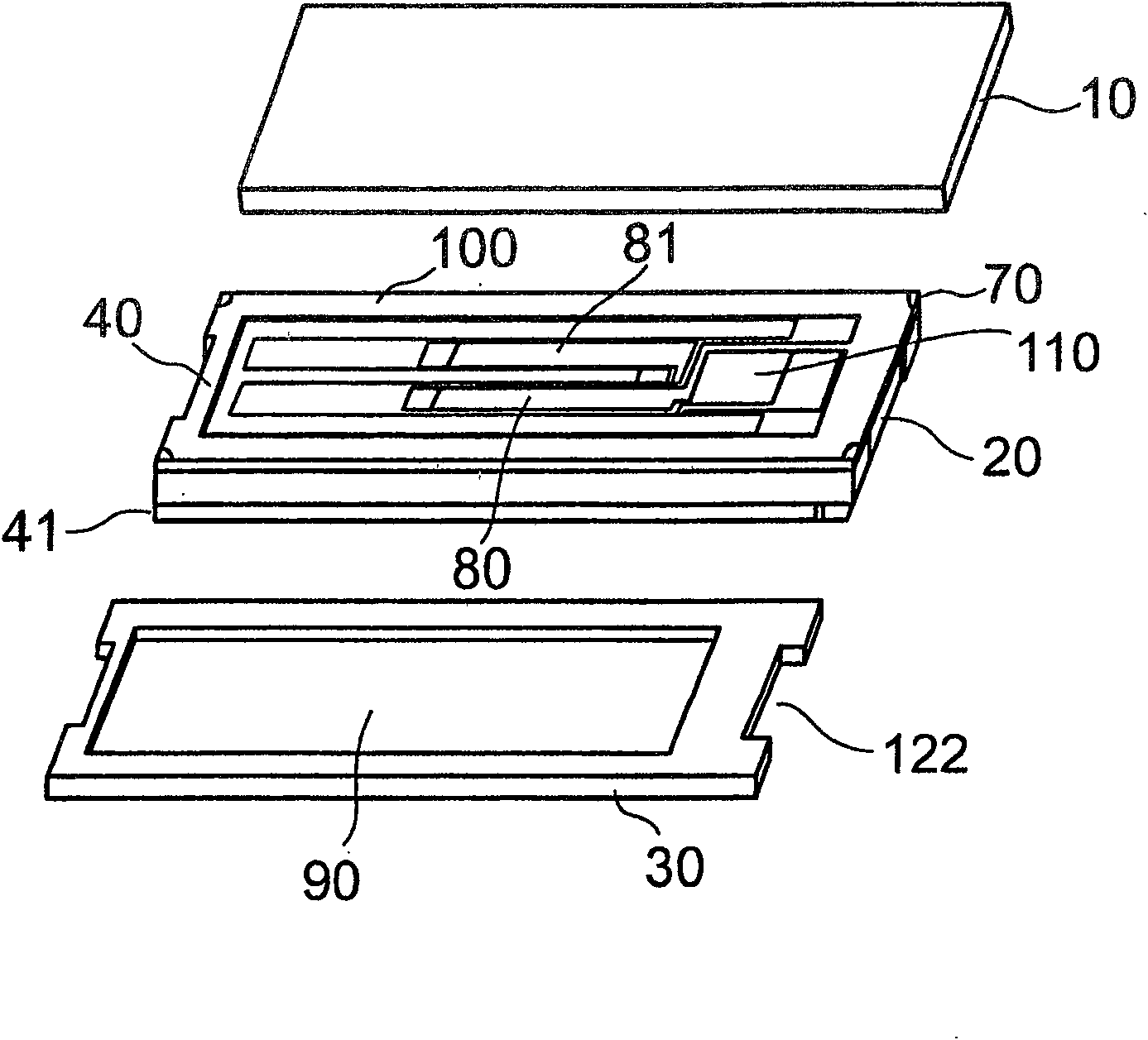

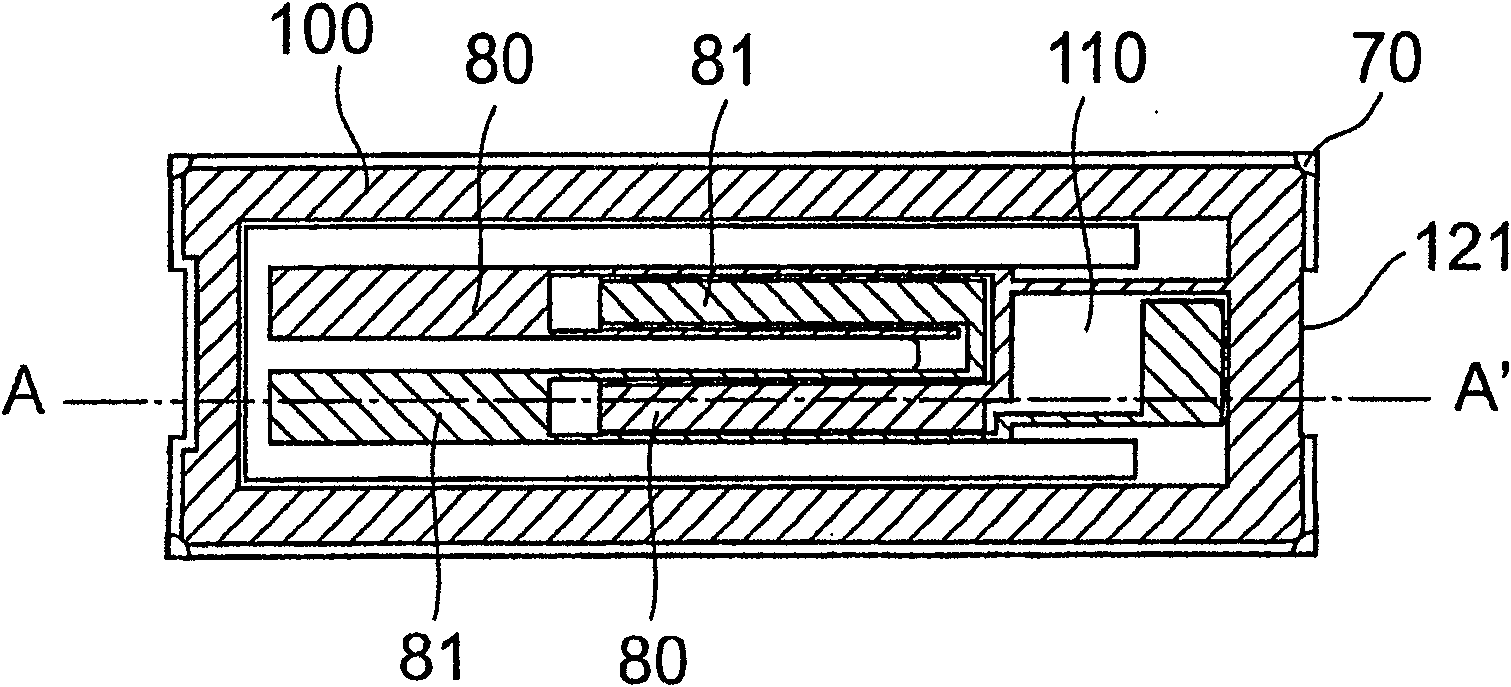

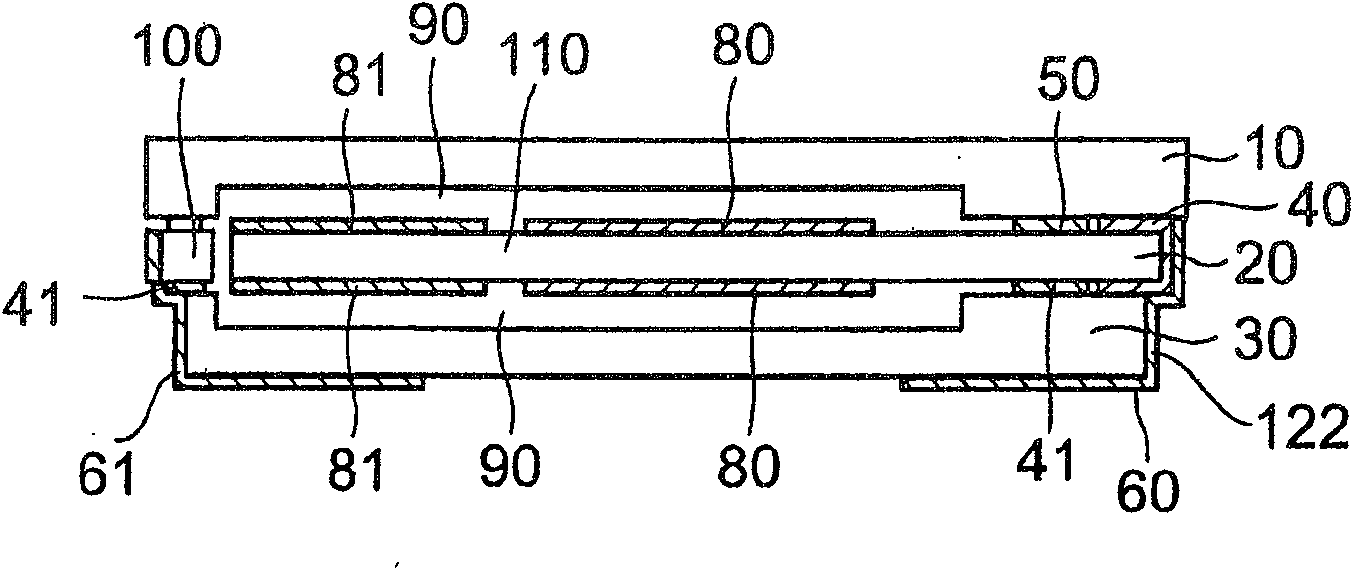

Image

Examples

Embodiment Construction

[0030] A method of manufacturing a piezoelectric vibrator according to the present invention is characterized in that the method has the steps of forming the vibrating member and the outer shape of the frame positioned at the periphery of the vibrating member, a step of forming a first excitation electrode at the vibrating member, and forming a first excitation electrode at the vibrating member. A process of forming a counterweight separate from the first excitation electrode, a process of adjusting the performance of the vibrator, a process of removing the first excitation electrode, a process of forming a metal film at the surface of the vibrator, and patterning the metal film and forming The process of the second excitation electrode.

[0031] In addition, the method of manufacturing a piezoelectric vibrator according to the present invention is characterized in that the method has a step of forming the external shape of a plurality of vibrating members and a frame of the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com