Flexible conductive connecting piece of flexible wire and preparation method thereof

A flexible conductive and flexible wire technology, applied in the direction of conductive connection, conductive adhesive connection, connection, etc., can solve the problems of poor conductivity of conductive adhesive, inability to meet the use environment with high conductivity requirements, damage to the flexibility of liquid metal wires, etc. Stable performance, simple structure and strong comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

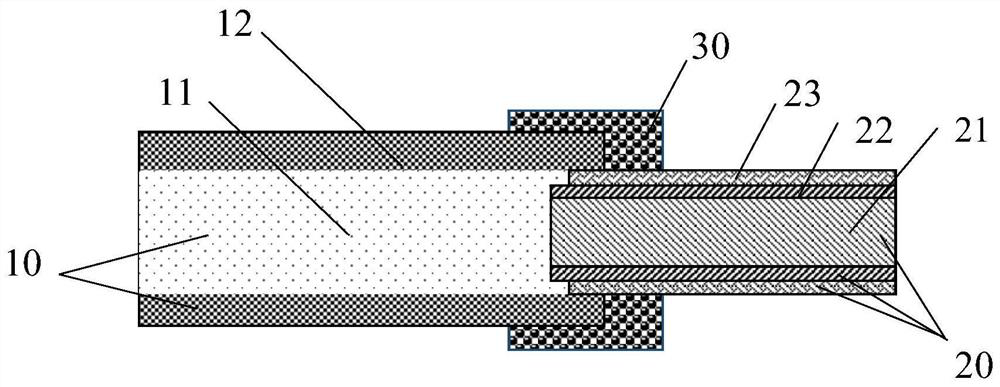

[0042] In this example, if figure 1 As shown, the flexible wire 10 includes liquid metal 11, which is formed by filling the liquid metal 11 in the elastic silicone tube 12, and the liquid metal is GaInSn.

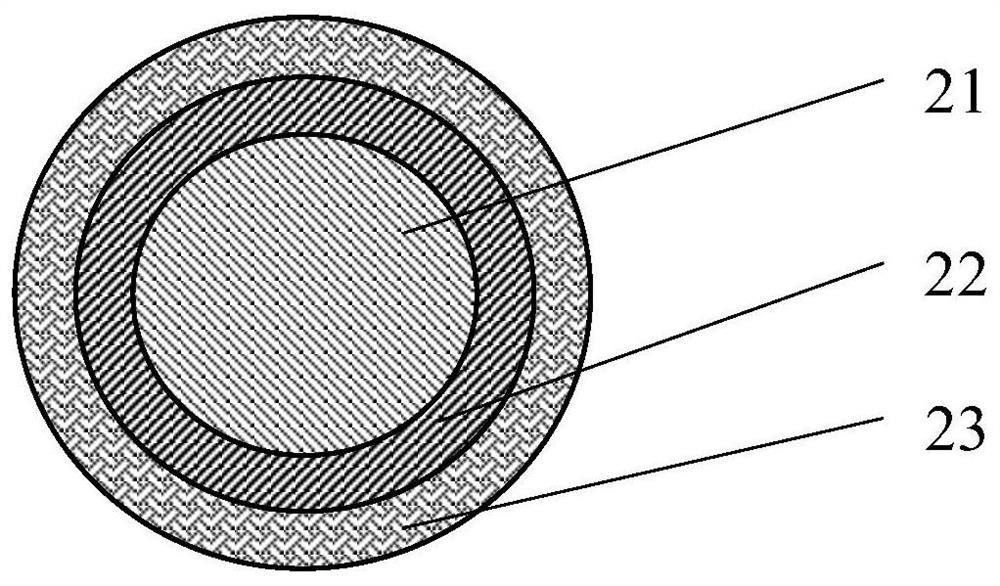

[0043] Such as figure 1 , 2 As shown, the flexible conductive connector 20 includes a flexible polymer wire 21 , a flexible conductive ring 22 and a flexible insulating ring 23 . Along the length direction of the flexible polymer wire, the flexible conductive ring 22 is sleeved on the periphery of the flexible polymer wire 21, the flexible insulating ring 23 is sleeved on the periphery of the flexible conductive ring 22, and one end of the flexible conductive ring 22 (referred to as the A end) ) remains bare and is not covered by the flexible insulating ring 23.

[0044] In this embodiment, the flexible polymer wire is made of flexible material polyethylene terephthalate (PET), the flexible conductive layer is made of conductive silver layer, and the flexible insulating la...

Embodiment 2

[0053] In this example, if figure 1 As shown, the flexible wire 10 includes liquid metal 11, which is formed by filling the liquid metal 11 in the elastic silicone tube 12, and the liquid metal is GaInSn.

[0054] Such as figure 1 , 2 As shown, the flexible conductive connector 20 includes a flexible polymer wire 21 , a flexible conductive ring 22 and a flexible insulating ring 23 . Along the length direction of the flexible polymer wire, the flexible conductive ring 22 is sleeved on the periphery of the flexible polymer wire 21, the flexible insulating ring 23 is sleeved on the periphery of the flexible conductive ring 22, and one end of the flexible conductive ring 22 (referred to as end A) The periphery of is left bare, not covered by the flexible insulating ring 23.

[0055] In this embodiment, the flexible polymer wire is made of polyurethane (PU), the flexible conductive layer is made of polyurethane (PU) doped with silver powder, and the flexible insulating layer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com