Apparatus for treating solutions with high osmotic strength

一种渗透液、溶液的技术,应用在海水的装置领域,能够解决限制发展等问题,达到提高回收率、低要求、高容器生产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

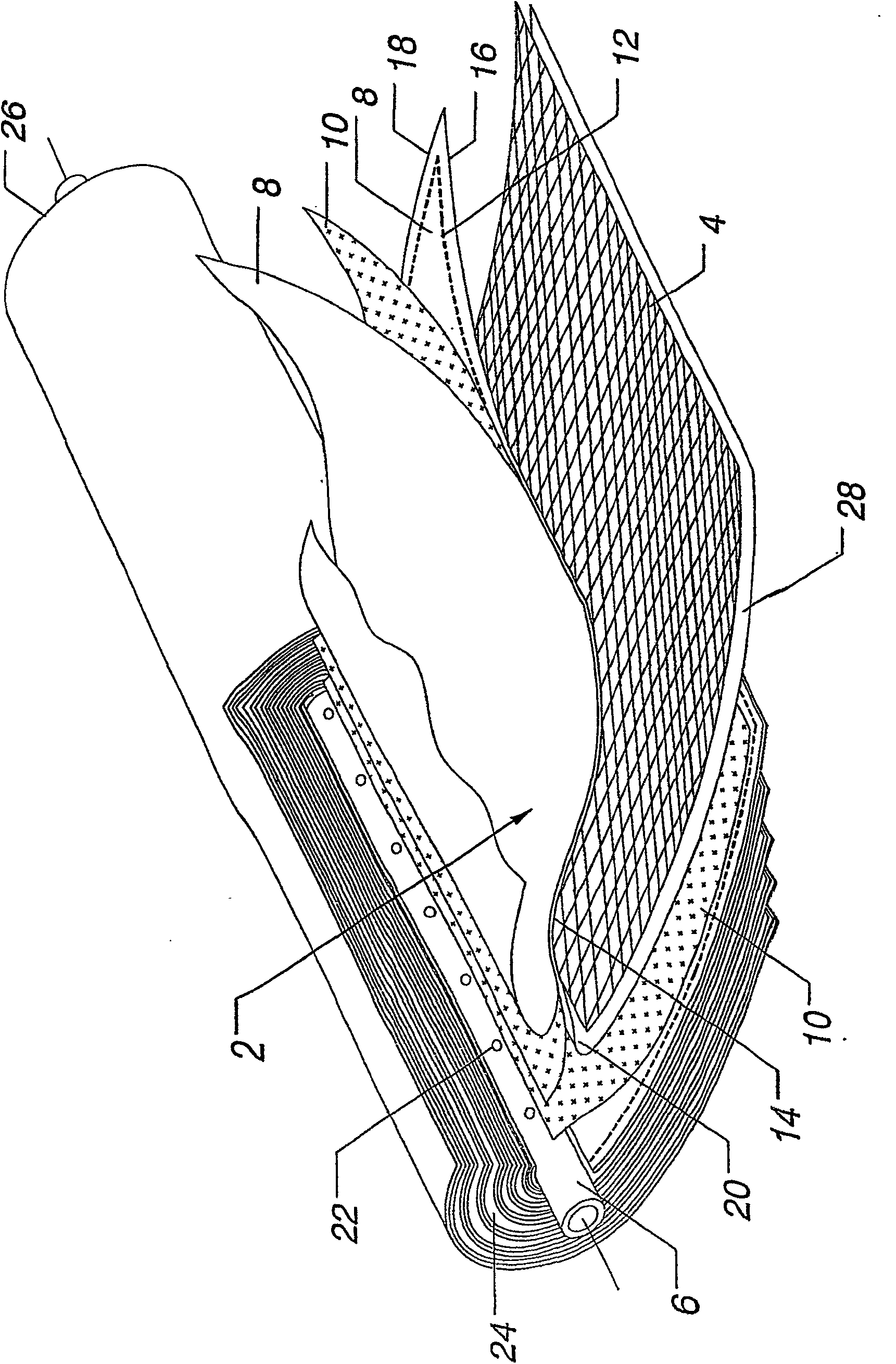

Method used

Image

Examples

Embodiment 1

[0081] FILMTEC SW30HR membrane is used to form the membrane element. Four elements having an effective membrane area of 2.6 square meters were constructed using FILMTECSW30SXLE membranes. Three SW30SXLE membrane elements were treated as follows: The membranes were immersed in 2000 ppm NaOCl aqueous solution at pH 10.5 for 30 minutes. Table 3 shows the measured standard specific fluxes and standard solute permeability for these elements.

[0082] Table 3. Components described in Example 1

[0083]

component

film

standard specific flux

L / m 2 / hr / bar (gfd / psi)

standard solute permeability

L / m 2 / hr (gfd)

A

SW30HR

1.07 (0.043)

0.29 (0.17)

B

SW30XLE

1.43 (0.058)

0.45 (0.26)

C

SW30XLE (processed)

2.12 (0.086)

0.33 (0.19)

D

SW30XLE (processed)

1.85 (0.075)

0.32 (0.19)

...

Embodiment 2

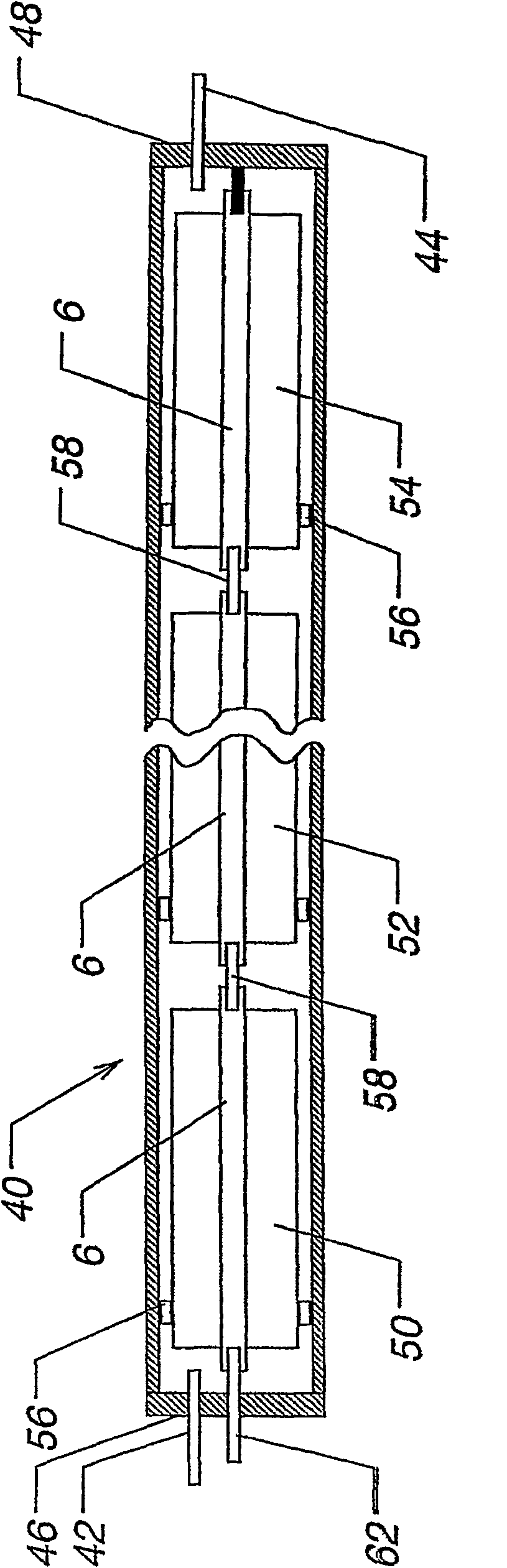

[0087] Two FILMTEC SW30XLE-380 elements were treated by immersing them for 30 minutes in an aqueous solution at pH 10.5 containing 1500 ppm and 2000 ppm NaOCl, respectively. These elements have the standard specific fluxes and standard solute permeabilities shown in Table 4, rows H and I. In addition, the standard specific flux and standard solute permeability values for the FILMTECS SW30HR-380 and SW30XLE-380 elements not in contact with NaOCl are shown in rows F and G, respectively. The ratio of the standard solute permeability to the standard specific flux of the terminal element (0.064) divided by the ratio of the standard solute permeability to the standard specific flux of the leading element (0.071) is less than 1. For all elements in Table 4, the standard pressure gradient is approximately 0.2 bar / meter and the feed spacer cross-sectional area is approximately 230 cm2.

[0088] Table 4. Components described in Example 2

[0089]

component

...

Embodiment 3 and comparative example 3 and 4

[0097] Use the method of Comparative Example 2 to simulate.

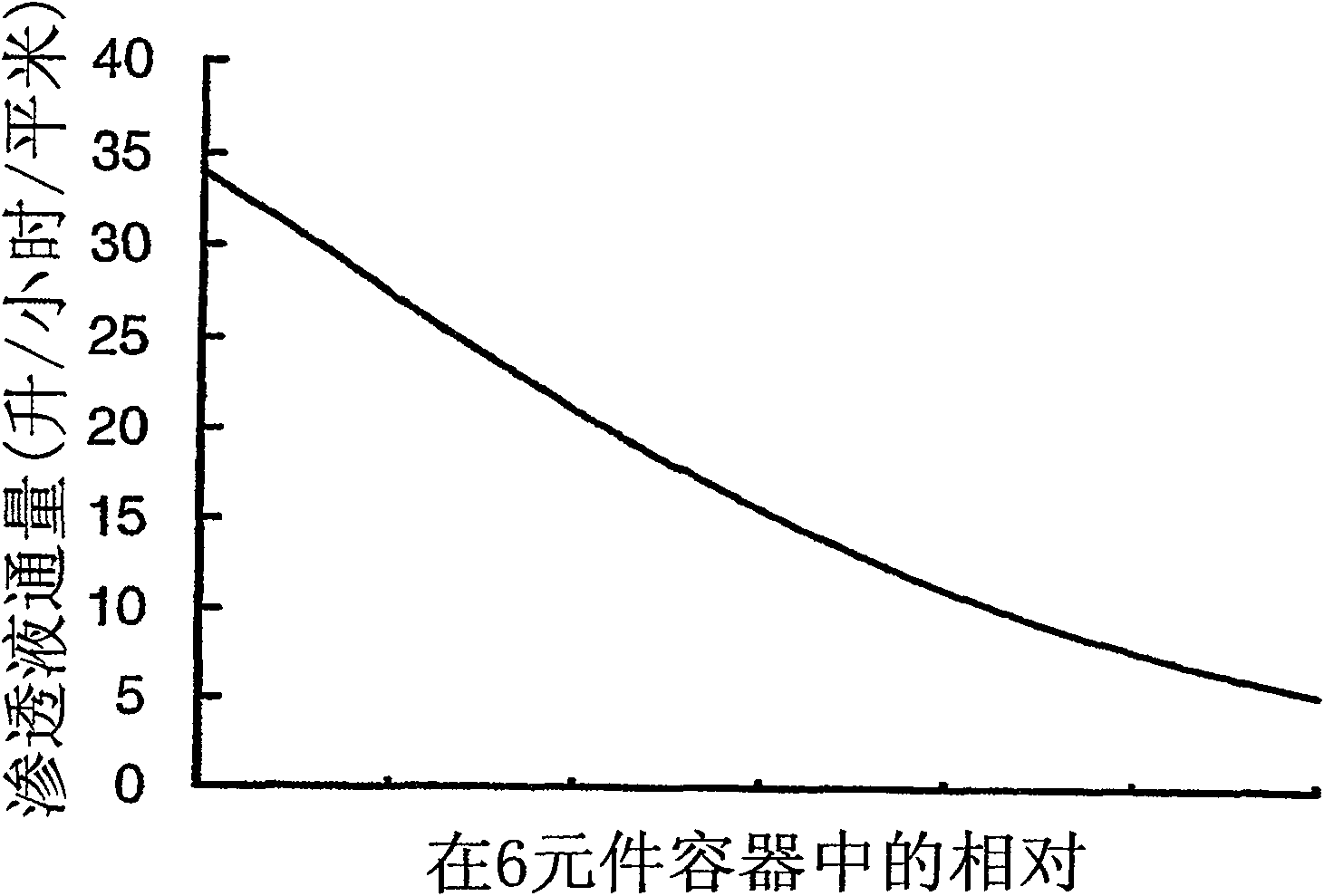

[0098] Tables 5-7 below provide the results of three simulations, each with a feed rate of 174 m3 / day (46000 gpd) of 3.8% seawater and a 50% recovery. Example 3 and Comparative Examples 3 and 4 simulated a pressure vessel containing 6 elements of 35.3 square meters (380 square feet), and the average flux of the vessel was 17 liters per square meter per hour (10 gfd). The specific fluxes (A values) of the membranes used in the elements are all within the easily available range. Assuming that the membrane solute permeability value (B value) is the same (0.068 L / m2 / h) for all elements in the vessel, this value is considered to have the least effect on flux within the operating range tested. The salt passage rate of the permeate from each element is approximately proportional to the assumed B value. For Example 3, Comparative Example 3, and Comparative Example 4, the calculated total permeate concentrations were 369 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com