Method for recovering heavy lubricating oil stock oil dewaxing solvent and method for dewaxing heavy lubricating oil stock oil

A technology of lubricating oil and raw material oil, which is applied in the recovery of heavy lubricating oil raw material oil dewaxing solvent and heavy lubricating oil raw material oil dewaxing process, which can solve the problems of high energy consumption and material consumption, and achieve reduced material consumption and simple operation , the effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Stir and mix 120g of crude oil with a boiling range of 410°C-580°C and 400g of ketonebenzene organic solvent at 30°C for 0.5h, and cool the resulting mixture to -25°C Crystallize, filter after 1h, obtain the filtrate containing heavy dewaxed lubricating oil stock oil and ketone benzene organic solvent, the ketone benzene organic solvent used for dewaxing is the mixture that methyl ethyl ketone and toluene mix and form, wherein the weight ratio of methyl ethyl ketone / toluene is 60 :40;

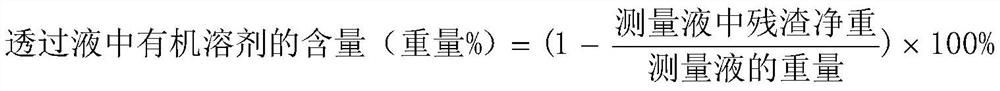

[0057] (2) Add 500mL of ketone-benzene solvent mixed by methyl ethyl ketone and toluene to the mother liquid tank of membrane separation device, wherein the mass ratio of methyl ethyl ketone / toluene is 60:40, the organic solvent resistant nanofiltration membrane (purchased from Win Chuang Special Chemical (Shanghai) Co., Ltd.'s asymmetric organic solvent-resistant nanofiltration membrane, brand PM280, molecular weight cut-off 280Da, membrane area of 0.0014m 2 ) into the membrane s...

Embodiment 2

[0062] (1) Stir and mix 180 g of crude oil with a boiling range of 410° C.-580° C. and 500 g of ketonebenzene organic solvent at 32° C. for 1 hour, and cool the resulting mixture to crystallize at -20° C. Filtrate after 2h to obtain the filtrate containing heavy dewaxed lubricating oil stock oil and ketonebenzene organic solvent, the ketonebenzene organic solvent used for dewaxing is the mixture formed by mixing methyl ethyl ketone and toluene, wherein the weight ratio of methyl ethyl ketone / toluene is 75:25 ;

[0063] (2) The concentrated solution in Example 1 is emptied, and the filtrate 500mL containing the dewaxed lubricating oil stock oil and the ketonebenzene organic solvent that step (1) obtains is added in the mother liquor tank, based on the total amount of the solution, The content of the dewaxed lubricating oil stock oil in this solution is 24% by weight, the weight ratio of methyl ethyl ketone / toluene in the solvent is 75:25, the system pressure is maintained at 3M...

Embodiment 3

[0068] (1) Stir and mix 150g of crude oil with a boiling range of 410°C-580°C and 450g of ketonebenzene organic solvent at 35°C for 1 hour, and cool the resulting mixture to -15°C for crystallization , filter after 2h, obtain the filtrate that contains dewaxing lubricating oil stock oil and ketone benzene organic solvent, the ketone benzene organic solvent that dewaxing uses is the mixture that methyl ethyl ketone and toluene mix and form, and wherein the weight ratio of methyl ethyl ketone / toluene is 70:30;

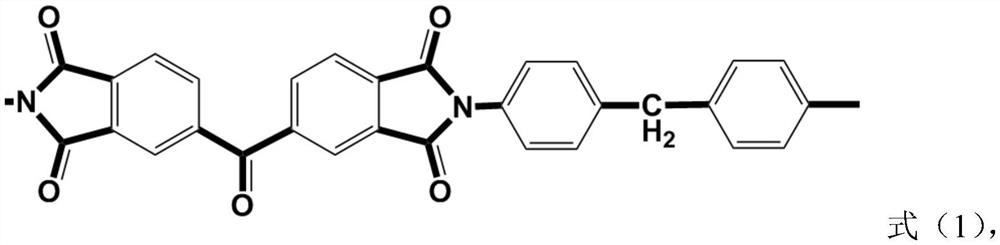

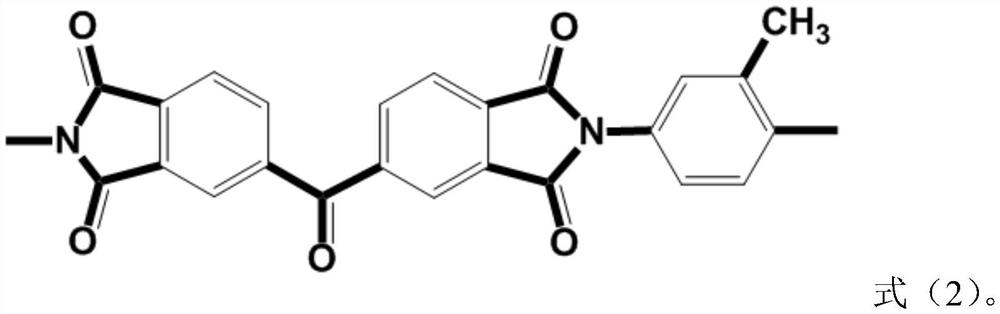

[0069] (2) Add 500mL of ketone-benzene solvent mixed by methyl ethyl ketone and toluene to the mother liquor tank of membrane separation device, wherein the mass ratio of methyl ethyl ketone / toluene is 70:30, and the organic solvent-resistant nanofiltration membrane that will cut (this organic-resistant The solvent nanofiltration membrane is a P84 polyimide membrane with a molecular weight cut-off of 250Da prepared according to the method disclosed in Example 7 of CN10167...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com