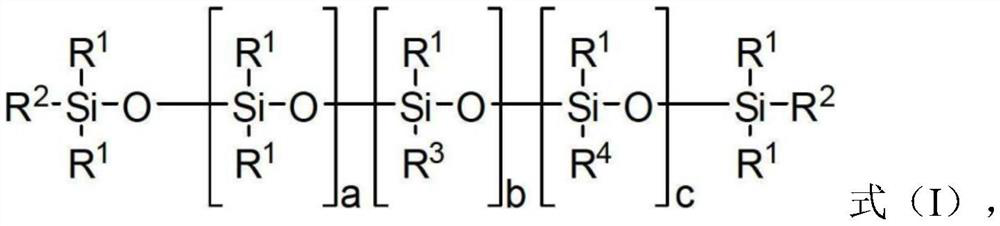

Method for removing impurities from synthetic rubber crude monomer by using composite nanofiltration membrane

A composite nanofiltration membrane and synthetic rubber technology, applied in the field of synthetic rubber, can solve the problems of high energy consumption and material consumption, and achieve the effects of continuous and stable production, stable operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The cut organic solvent-resistant composite nanofiltration membrane (this organic solvent-resistant composite nanofiltration membrane was purchased from Evonik Specialty Chemicals, the molecular weight cut-off is 300Da, the product brand PMselective, and the effective area of the membrane is 0.0014m 2 ) into the membrane separation module, connect the membrane separation device, add 500mL isoprene to the raw material tank of the membrane separation device, turn on the power pump, fill the raw material tank with high-purity nitrogen, keep the pressure at 2MPa, wash the membrane After 2h, empty the feed liquid.

[0052] At 25°C, add 600mL of isoprene and 0.01g of p-tert-butylcatechol to the above-mentioned membrane separation device, stir for 0.1h, then add 0.05g of water, stir for 0.1h to form a raw material liquid, and then turn it on System, the pressure is maintained at 3MPa, the temperature of the raw material tank is controlled by a water bath at 30°C, the membran...

Embodiment 2

[0055] To the raw material solution in Example 1, add 0.03 g of polymerization inhibitor TBC, add 0.1 g of water, open the system, keep the pressure at 2.5 MPa, and control the temperature of the raw material tank at 40° C., and start the process after the system runs continuously for 4 hours. In the membrane separation experiment, the raw material liquid was sampled before pressurization.

[0056] Samples were taken to determine the water content and the p-tert-butylcatechol content in the crude isoprene monomer raw material liquid, respectively. After the membrane separation experiment, the water content and p-tert-butylcatechol content in the sample obtained after impurity removal were measured. At the same time, the flux of the organic solvent in the impurity removal process of the nanofiltration membrane was measured. See Table 1 for the measurement results.

Embodiment 3

[0058] To the raw material solution in Example 2, add 0.45 g of polymerization inhibitor TBC, add 4.9 g of water, open the system, keep the pressure at 1.5 MPa, control the temperature of the raw material tank with a water bath to 20 ° C, and start the system after 4 hours of continuous operation In the membrane separation experiment, the raw material was sampled before pressurization.

[0059] Samples were taken to determine the water content and the p-tert-butylcatechol content in the crude isoprene monomer raw material liquid, respectively. After the membrane separation experiment, the water content and p-tert-butylcatechol content in the sample obtained after impurity removal were measured. At the same time, the flux of the organic solvent in the impurity removal process of the nanofiltration membrane was measured. See Table 1 for the measurement results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com