Impurity removal method of synthetic rubber crude monomer

A technology for synthesizing rubber and monomers, used in chemical instruments and methods, purification/separation of hydrocarbons and hydrocarbons, etc. It can solve the problems of high energy consumption and material consumption, and achieve continuous and stable production, stable operation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

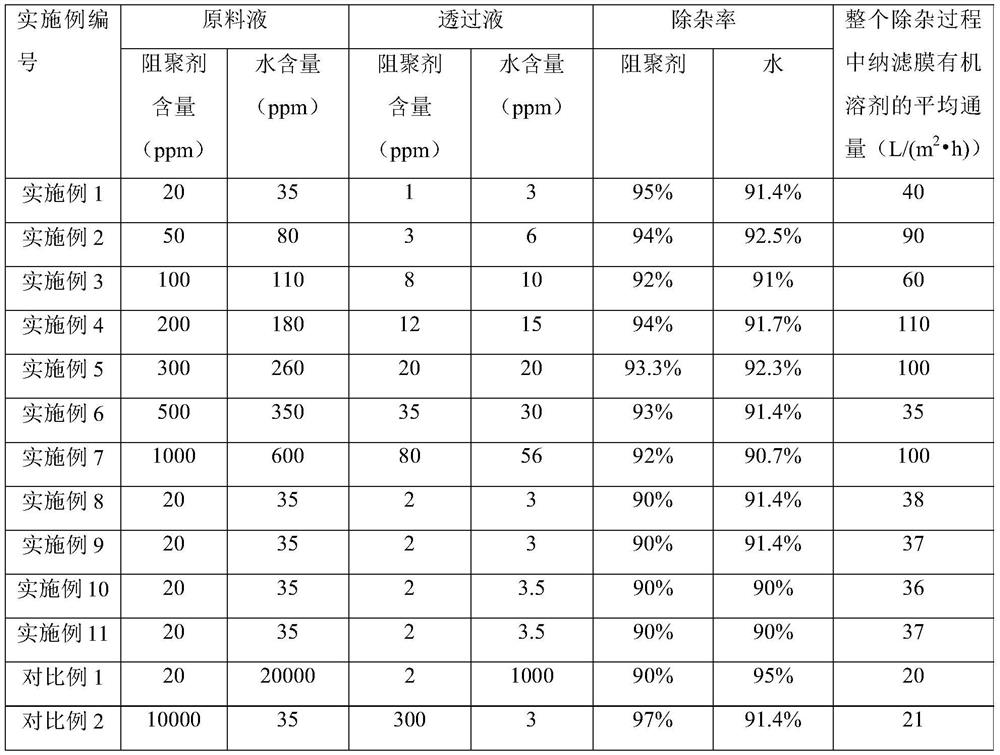

Embodiment 1

[0046] With the cut organic solvent resistant nanofiltration membrane (this organic solvent resistant nanofiltration membrane is purchased from Evonik Specialty Chemicals, the molecular weight cut-off is 280Da, the product brand is PM280, and the effective area of the membrane is 0.0014m 2 ) into the membrane separation module, connect the membrane separation device, add 500mL of isoprene to the mother liquor tank of the membrane separation device, turn on the power pump, fill the mother liquor tank with high-purity nitrogen, keep the pressure at 2MPa, and wash the membrane After 2h, empty the feed liquid.

[0047] At 25°C, add 550ml of isoprene and 0.008g of p-tert-butylcatechol (TBC) to the above-mentioned membrane separation device, stir for 0.1h, then add 0.04g of water, and stir for 0.1h to form a raw material solution , and then turn on the system, keep the pressure at 2MPa, control the temperature of the mother liquid tank at 25°C with a water bath, start the membrane...

Embodiment 2

[0050] The cut organic solvent resistant nanofiltration membrane (this organic solvent resistant nanofiltration membrane is a P84 polyimide membrane with a molecular weight cut-off of 250Da prepared according to the method disclosed in CN101678286A in Example 7, the membrane area 0.0014m 2 ) into the membrane separation module, connect the membrane separation device, add 500mL of isoprene to the mother liquor tank of the membrane separation device, turn on the power pump, fill the mother liquor tank with high-purity nitrogen, keep the pressure at 2.5MPa, wash After 2 hours of filming, the feed liquid was emptied.

[0051] At 25°C, add 550ml of isoprene to the above-mentioned membrane separation device, add 0.018g of polymerization inhibitor p-tert-butylcatechol, stir for 0.5h, then add 0.09g of water, stir for 0.5h, and form a raw material solution , and then turn on the system, keep the pressure at 2.5MPa, control the temperature of the mother liquid tank at 45°C with a wate...

Embodiment 3

[0054] The cut organic solvent resistant nanofiltration membrane (this organic solvent resistant nanofiltration membrane is a P84 polyimide membrane with a molecular weight cut-off of 330Da prepared according to the method disclosed in CN101678286A in Example 7, the membrane area 0.0014m 2 ) into the membrane separation module, connect the membrane separation device, add 500mL of isoprene to the mother liquor tank of the membrane separation device, turn on the power pump, fill the mother liquor tank with high-purity nitrogen, keep the pressure at 2.5MPa, wash After 2 hours of filming, the feed liquid was emptied.

[0055] At 25°C, add 550ml of isoprene and 0.038g of p-tert-butylcatechol to the above-mentioned membrane separation device, stir for 0.3h, then add 0.06g of water, stir for 0.3h to form a raw material solution, and then turn it on System, the pressure is maintained at 2MPa, the temperature of the mother liquid tank is controlled by a water bath to 40°C, and the mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com