Plastic rod lens, rod lens array, rod lens plate, image sensor, and printer

A technology of plastic rods and rod lenses, applied in the directions of lenses, instruments, printing, etc., can solve the problem of no plastic rod lenses, and achieve the effect of small chromatic aberration and good color characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0219] The stock solution of each layer was prepared as shown in Table 2 below.

[0220]

[0221] In addition, in order to suppress crosstalk and flickering, dye BlueACR (NIPPON KAYAKU CO., LTD. Manufactured), dye Blue 4G (manufactured by Mitsubishi Chemical), dye MS yellow HD-180 (manufactured by Mitsui Topress Dye Co., Ltd.), dye MS MagentaHM-1450 (manufactured by Mitsui Topress Dye Co., Ltd.), dye KAYASORB CY-10 (manufactured by NIPPONKAYAKU CO., LTD.).

[0222] table 3

[0223] dye

Layer 4 (mass%)

Layer 5 (mass%)

Blue ACR

0.014

0.571

Blue 4G

0.011

0.011

MS Magenta HM-1450

0.014

0.143

MS Yellow HD-180

0.014

0.143

KAYASORB CY-10

0.011

0.011

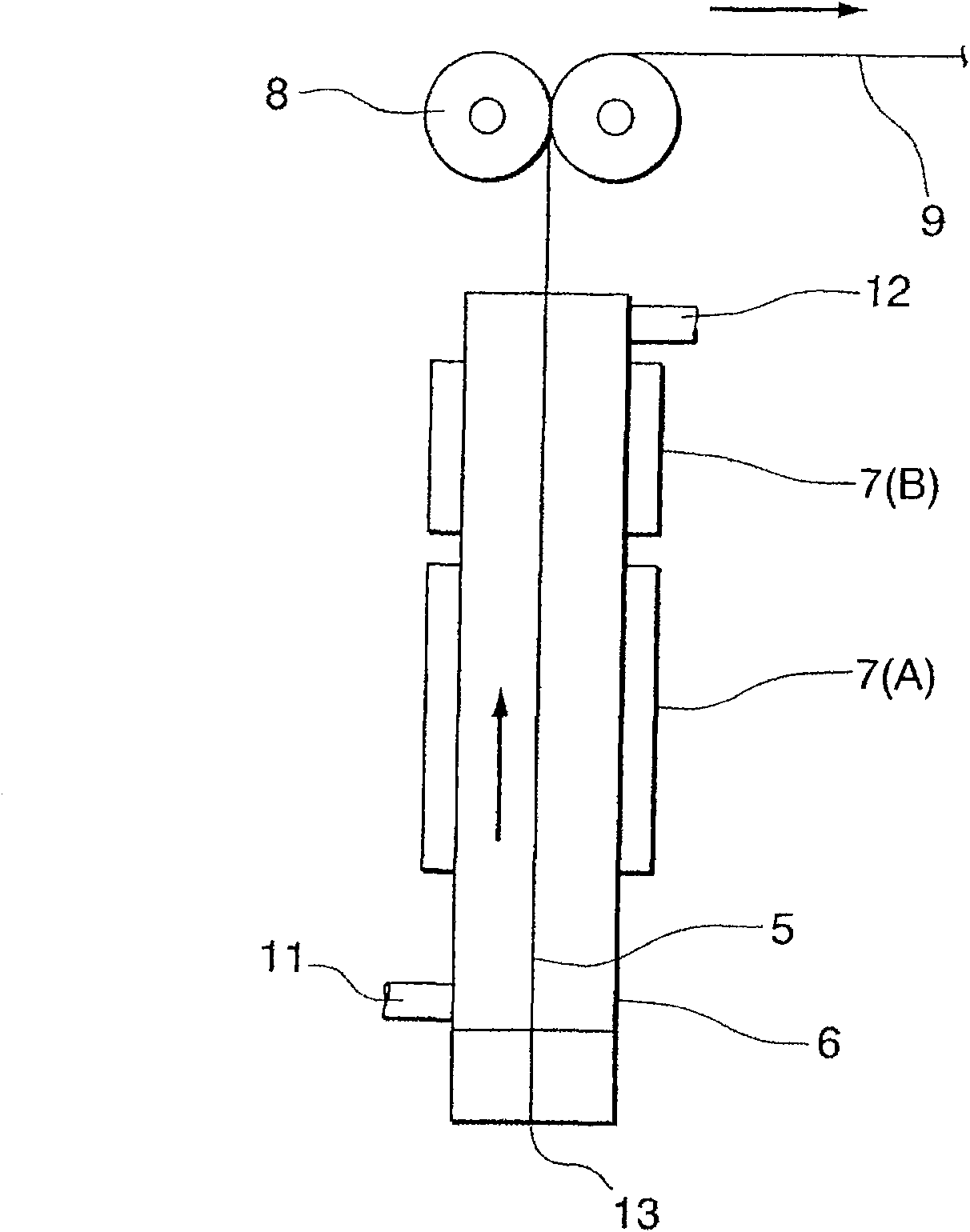

[0224] Thereafter, each layer was heated and kneaded to 70° C., and the cured concentric 5-layer composite yarn with a lowered refractive index was sequentially arranged from the center and extruded simultaneously from the n...

Embodiment 2

[0244] A plastic rod lens was manufactured in the same manner as in Example 1 except that the draw ratio was changed to 3.50 times and the relaxation rate was changed to 500 / 700.

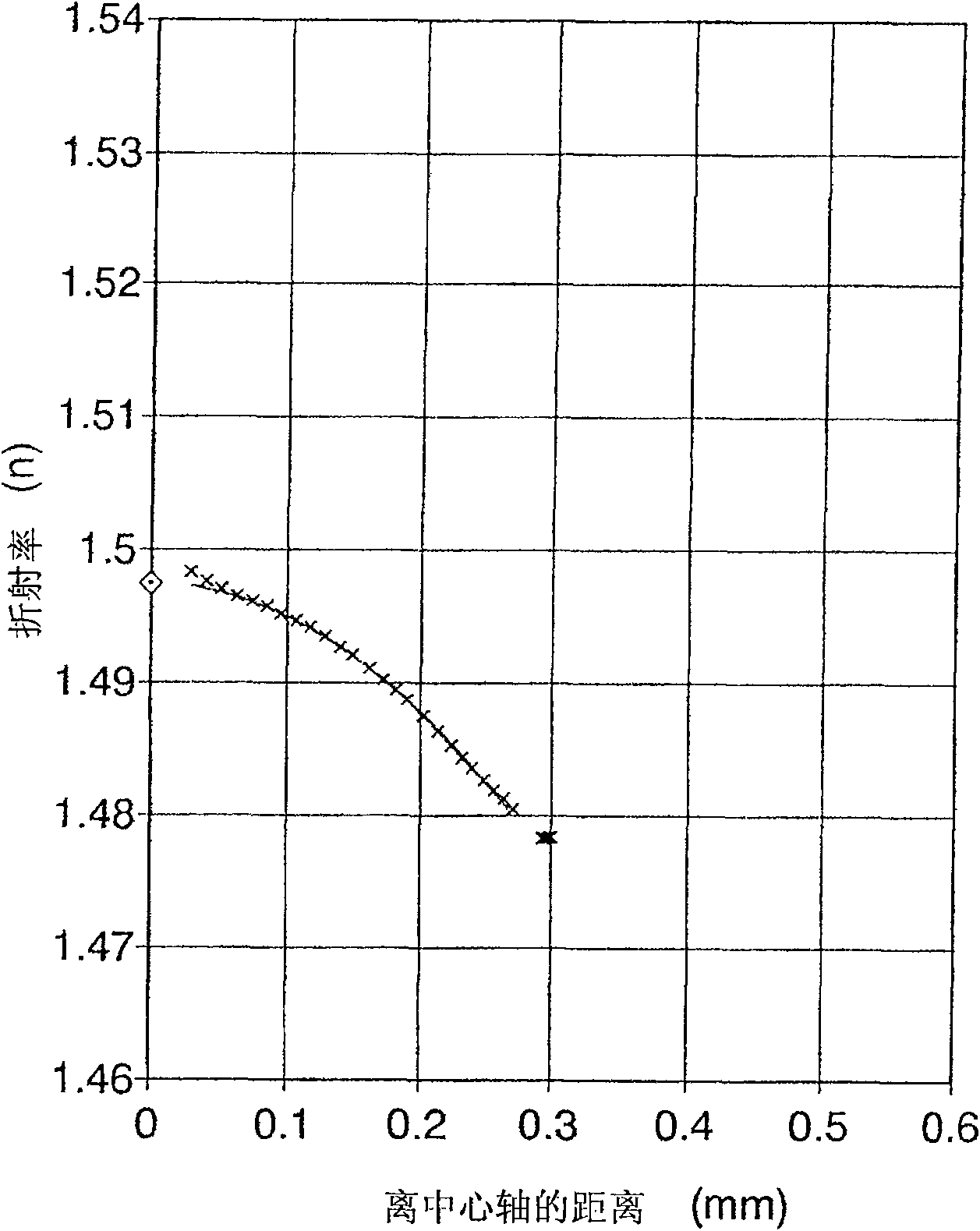

[0245] The radius R of the obtained plastic rod lens is 0.187 mm, and the central refractive index is 1.497. The refractive index distribution in the range of 0.2R to 0.8R from the central axis to the outer periphery is similar to formula (5). In the case of a wavelength of 525nm, the refractive index The distribution constant g is 0.84mm -1 .

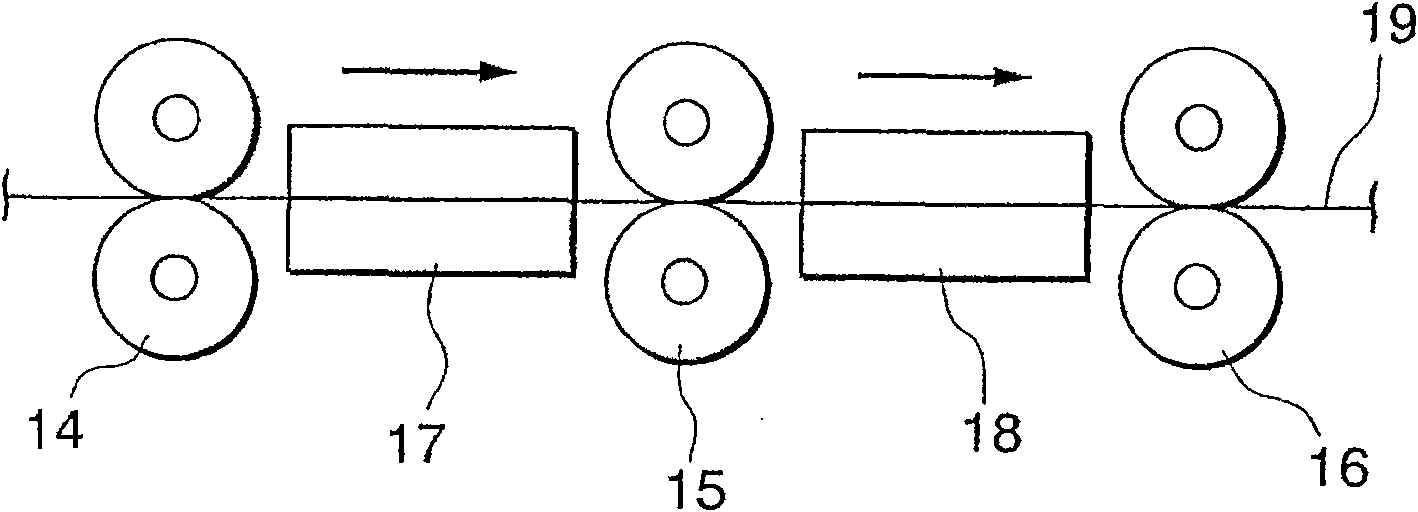

[0246] Next, it was the same as in Example 1, except that the distance between the plastic rod lenses was changed from 0.37 mm to 0.39 mm, and the adhesive was changed from "Araldite Rapid" to "s-dine 9607K" manufactured by SEKISUI FULLER Co., Ltd. Fabricated to produce a rod lens array.

[0247] The conjugate length Tc of the rod lens array at 525 nm is 10.0 mm, and the MTF at this time is 72.6%.

[0248] The Tc of the rod lens array was measured at each...

Embodiment 3

[0250] Except having changed the addition amount of the dye of the 4th layer as shown in the following Table 5, it manufactured similarly to Example 2, and manufactured the plastic rod lens and the rod lens array.

[0251] table 5

[0252] dye

Layer 4 (mass%)

Blue ACR

0.003

Blue 4G

0.003

MS Magenta HM-1450

0.003

MS Yellow HD-180

0.006

KAYASORB CY-10

0.003

[0253] The radius R of the obtained plastic rod lens is 0.187 mm, and the central refractive index is 1.497. The refractive index distribution in the range of 0.2R to 0.8R from the central axis to the outer periphery is similar to formula (5). In the case of a wavelength of 525nm, the refractive index The distribution constant g is 0.84mm -1 .

[0254] The conjugate length Tc of the rod lens array is 10.0mm in the case of 525mm, and the MTF at this time is 62.4%.

[0255] The Tc of the rod lens array was measured at each wavelength of 470 nm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com