Composite rigid body train line and its production method

A rigid body and trolley line technology, applied in the direction of power lines, vehicle components, power rails, etc., can solve the problems of reduced current collection efficiency, shortened service life of sliding contact rails, and reduced contact area, so as to reduce contact resistance and stick tightly High performance, the effect of improving the collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

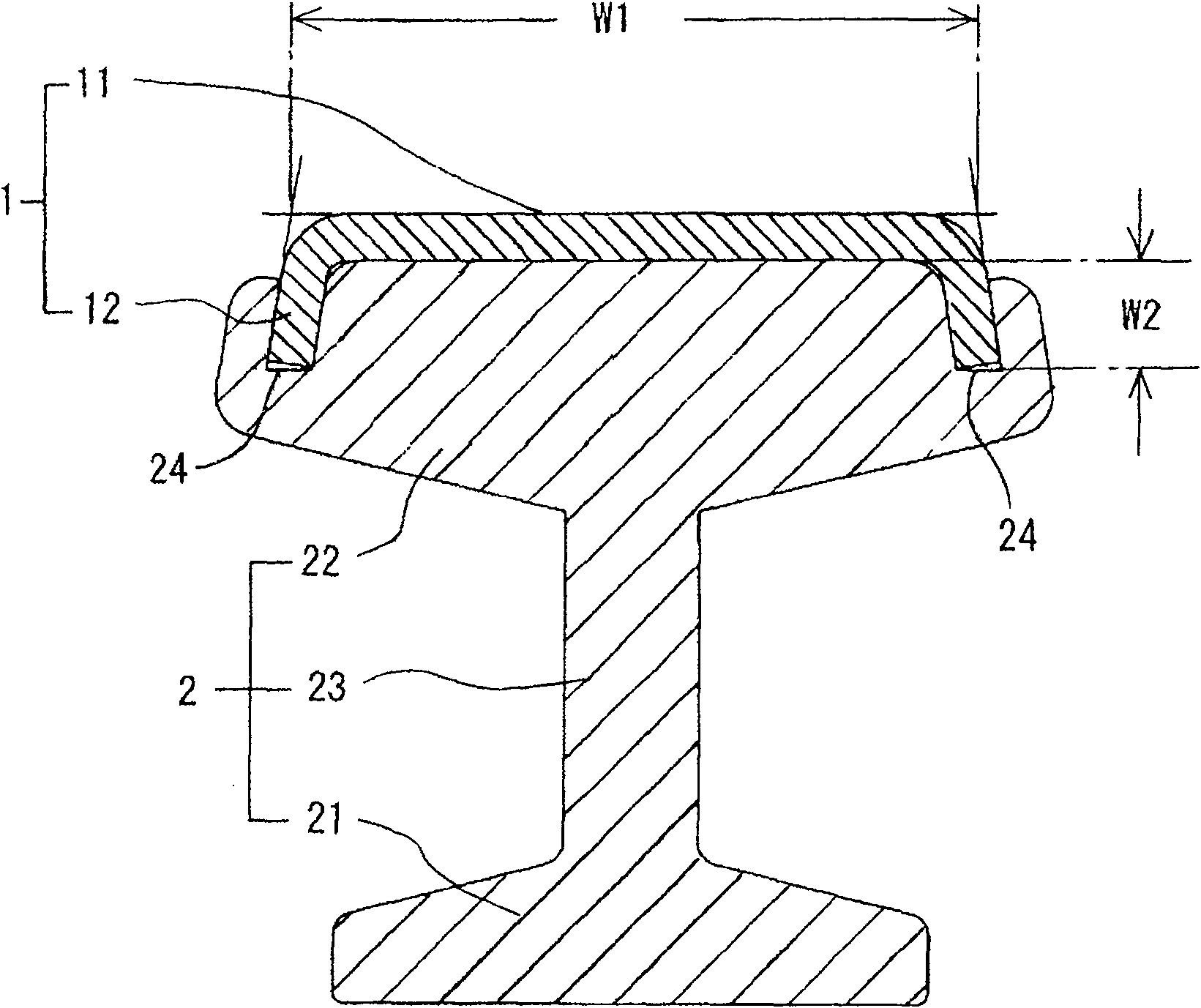

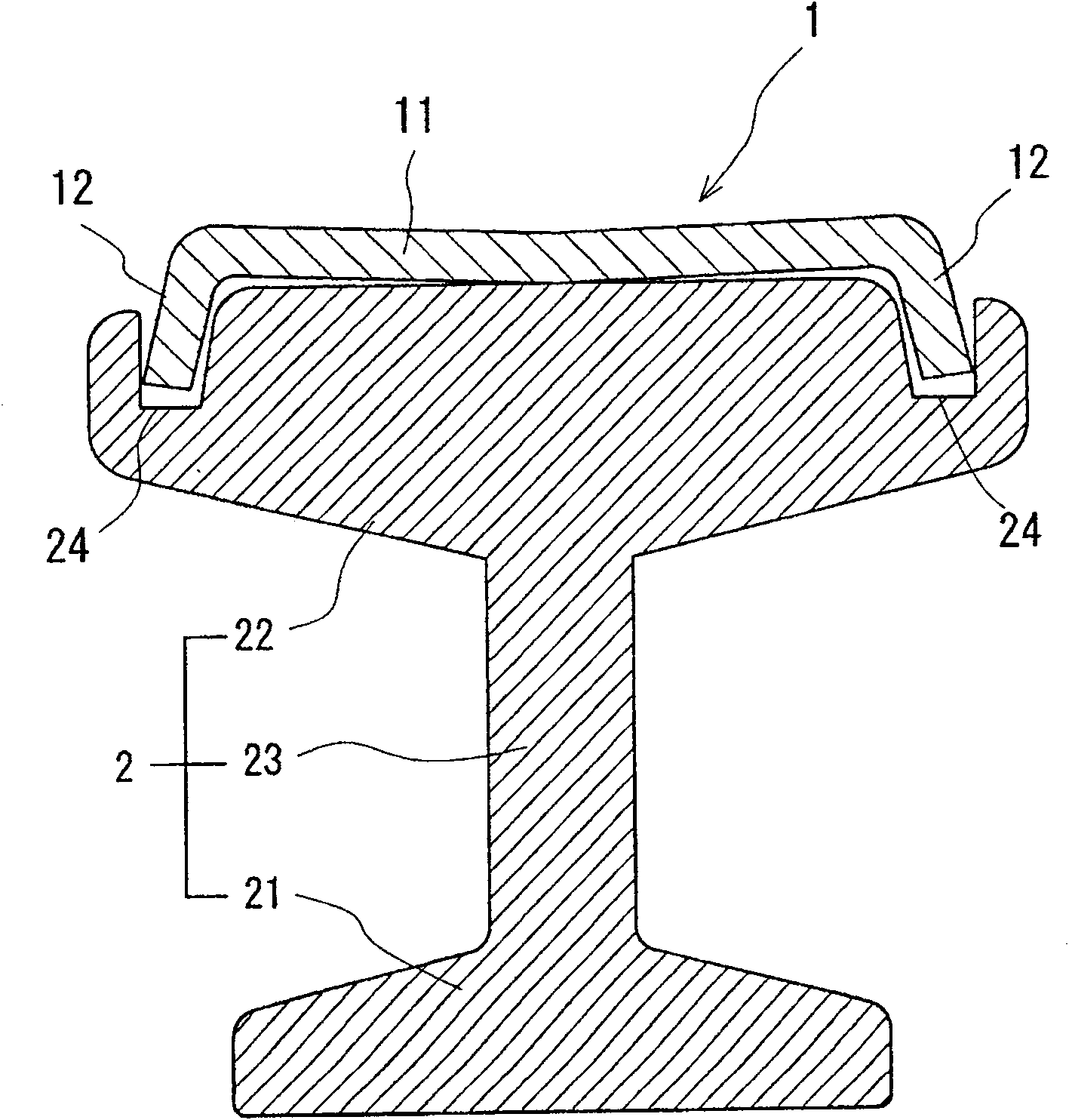

[0060] Rail seat material: aluminum alloy (JIS A6063-T5)

[0061] Width of riveted front rail seat pedestal: 114mm

[0062] The height of the rail seat: 99mm

[0063] Width of connecting piece: 18mm

[0064] Material of sliding contact rail: stainless steel (SUS304)

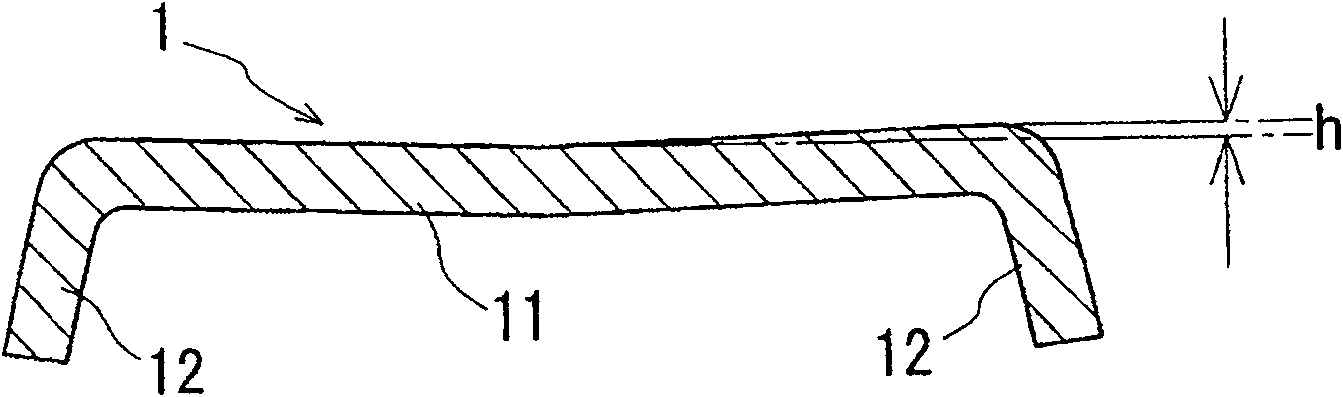

[0065] The warping amplitude h of the sliding contact rail: 1.5mm±0.5mm (considering the processing tolerance)

[0066] Center piece width W1 of sliding contact rail: about 92mm

[0067] Side piece width W2 of sliding contact rail: about 14.3mm

[0068] Ratio W1 / W2: About 6.4

[0069] Width of sliding contact rail: 6mm

Embodiment 2

[0074] and with figure 1 In the same structure, the production of rigid train lines with different ratios W1 / W2 and thicknesses of sliding contact rails was also tried. As a result, when the ratio W1 / W2 is 3.0 or more and the thickness of the sliding contact rail is 5.0 mm or more, it can be confirmed that the central piece of the sliding contact rail is in contact with the rail seat on the entire surface in the width direction, and has a high flatness.

[0075] The train line of the present invention can be suitably utilized as a composite rigid body train line for subways, monorails, new transportation systems, and the like. The manufacturing method of the present invention can be suitably utilized in the manufacture of such a composite rigid body train wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com