Vertical chain driven grinding ball continuous casting production line

A technology of casting production line and chain transmission, which is applied in foundry workshops, casting equipment, manufacturing tools, etc., can solve the problems of poor quality of grinding balls, high labor intensity, large working area, etc., and achieve good surface quality, high shape effect, large Effect of Gear Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

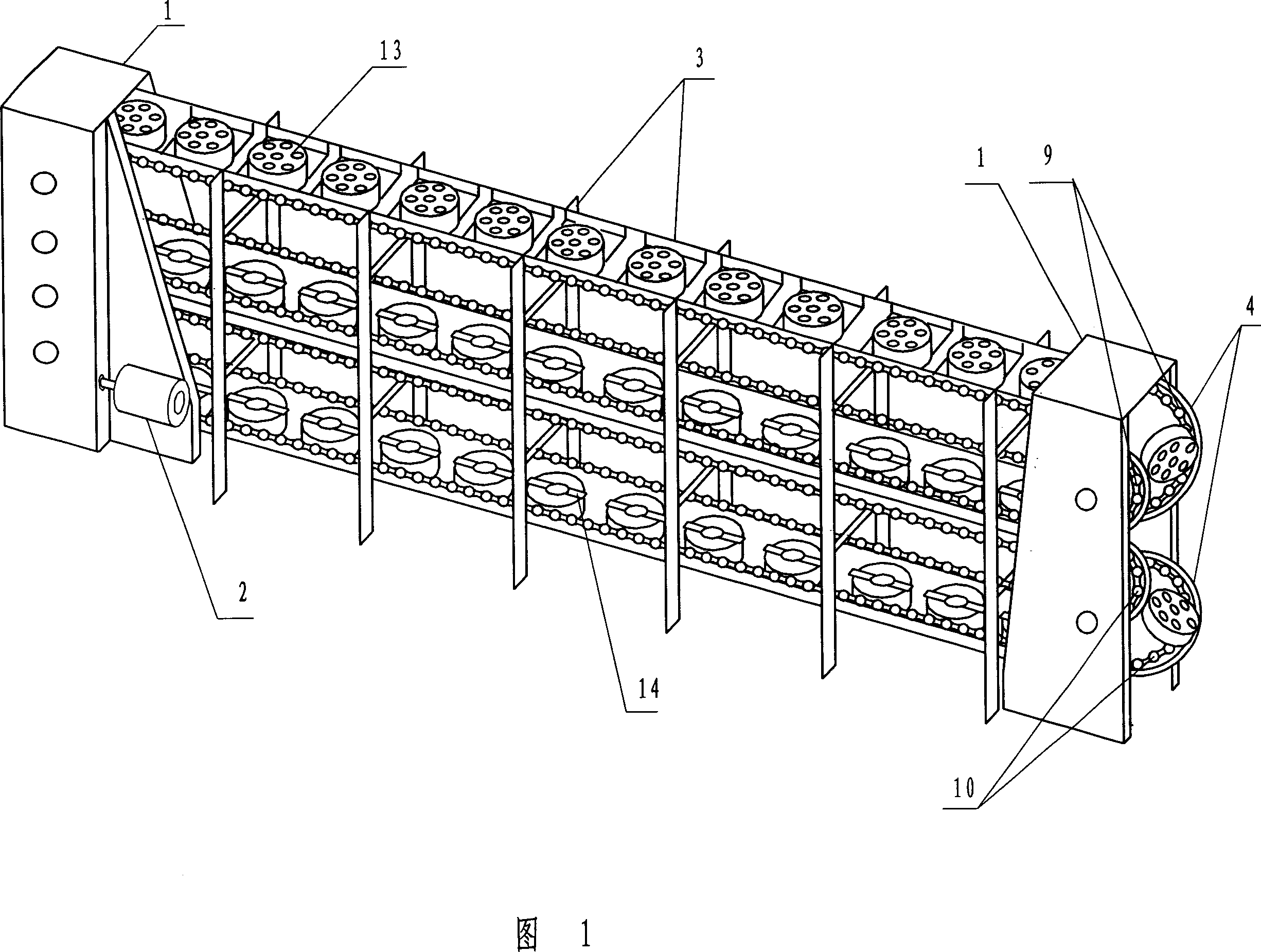

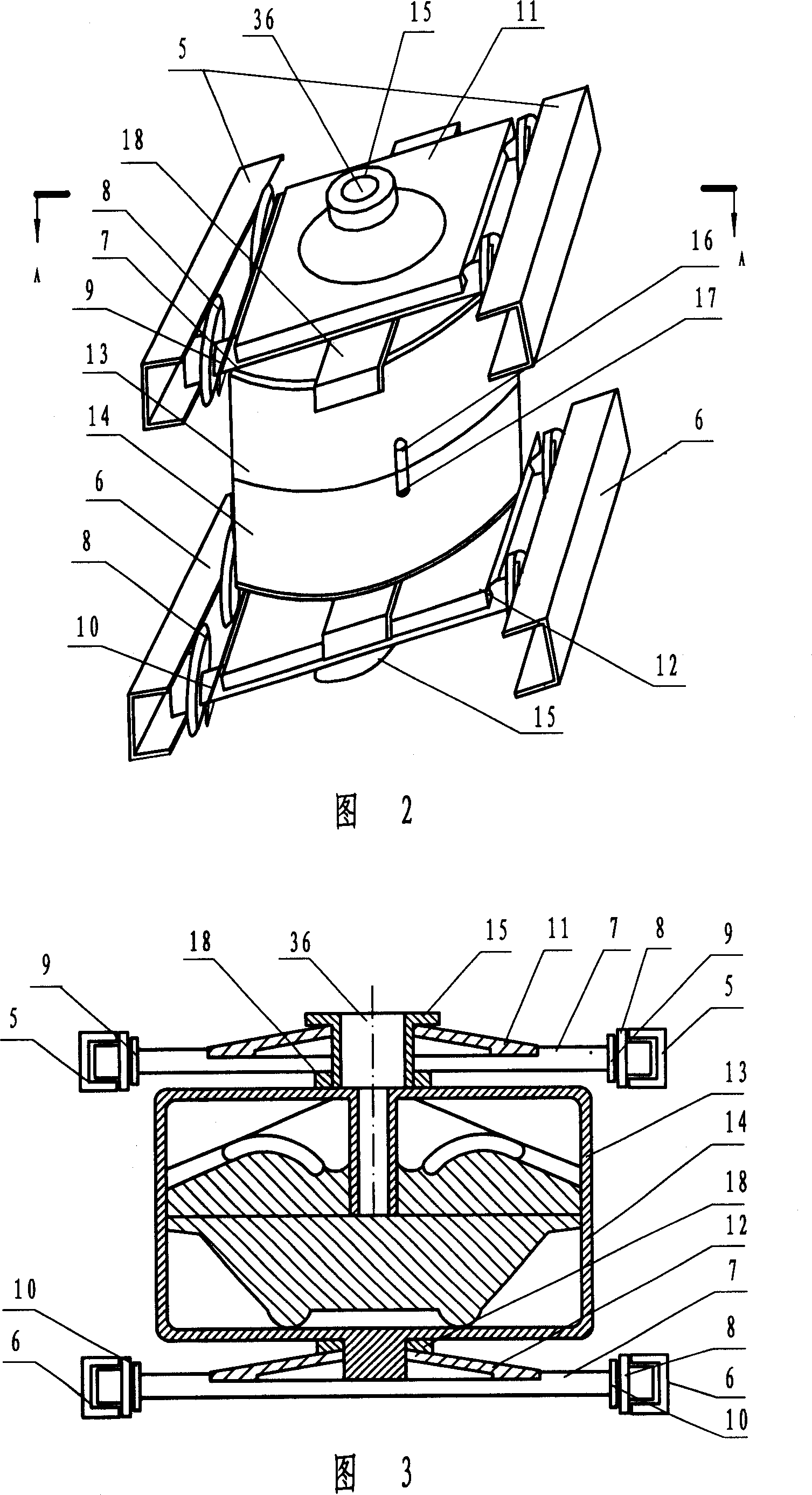

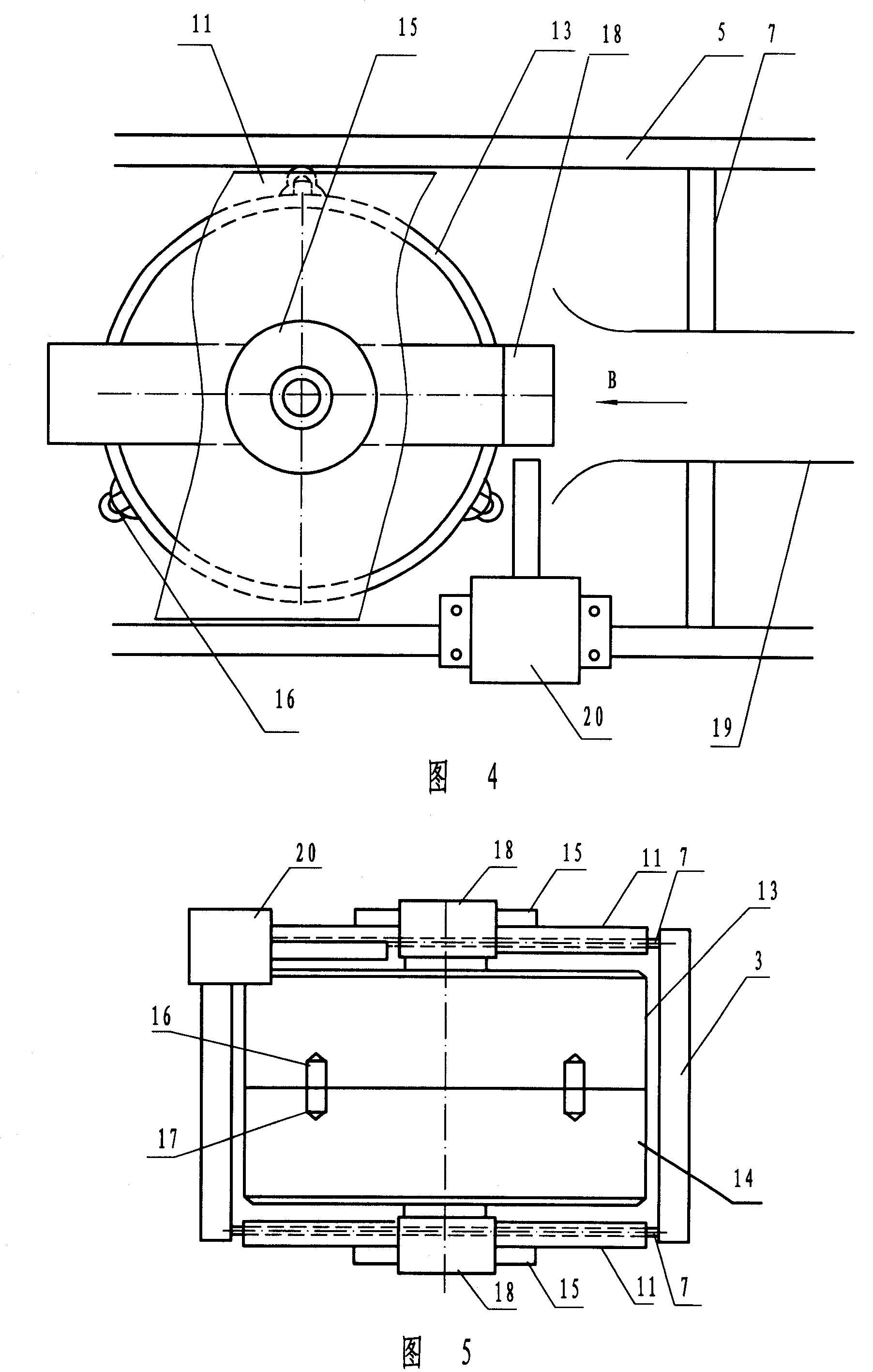

[0028] The vertical chain drive grinding ball continuous casting production line of the present invention will be further described in detail below in conjunction with the accompanying drawings;

[0029] It can be seen from Fig. 1 that the vertical chain drive grinding ball continuous casting production line in this embodiment includes a motor 2 fixed on the left end of the box body 1, a truss 3 fixed on both sides of the production line, and a sprocket wheel 4 fixed in the box body 1 at both ends of the production line and The multi-stage differential gear reduction device fixed in the left end of the box body 1 and connected to the motor 2 controls the transmission of the production line. This production line uses a single differential sheave that is currently mature in the market to drive the two-station active sprocket to realize double-chain The effect of precise synchronous positioning under the transmission, the device is novel in structure, reliable in action, simple in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap