Laser pollution removing system and method

A laser and laser beam technology, applied in lasers, laser welding equipment, laser parts and other directions, can solve problems such as environmental pollution, contact wear, dust falling, etc., to avoid environmental pollution and improve the effect of labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] While the invention will be fully described with reference to the accompanying drawings, which contain preferred embodiments of the invention, it should be understood before proceeding that those skilled in the art may modify the invention described herein while still obtaining the benefits of the invention. Therefore, it should be understood that the following description is a broad disclosure for those skilled in the art, and its content is not intended to limit the present invention.

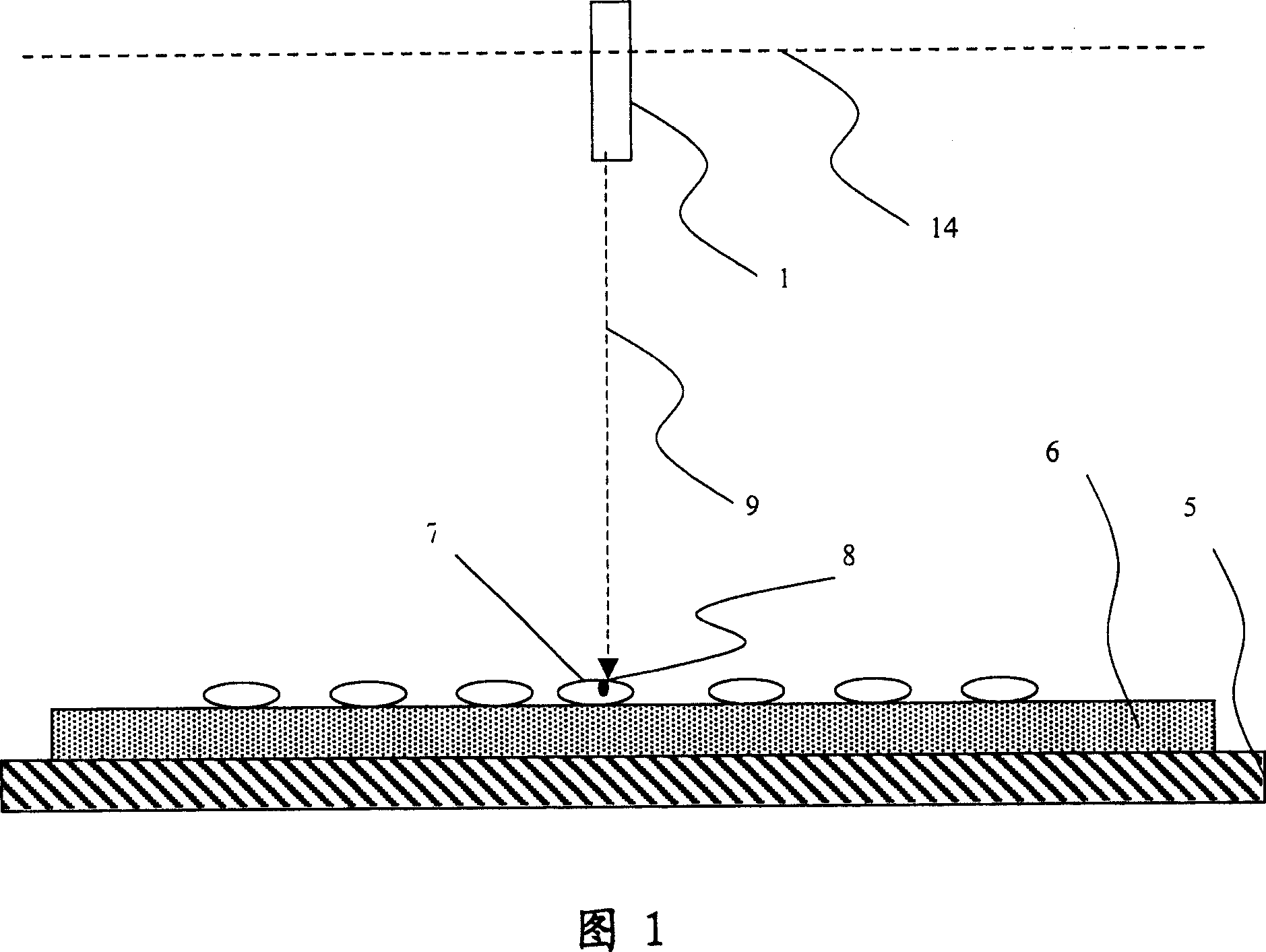

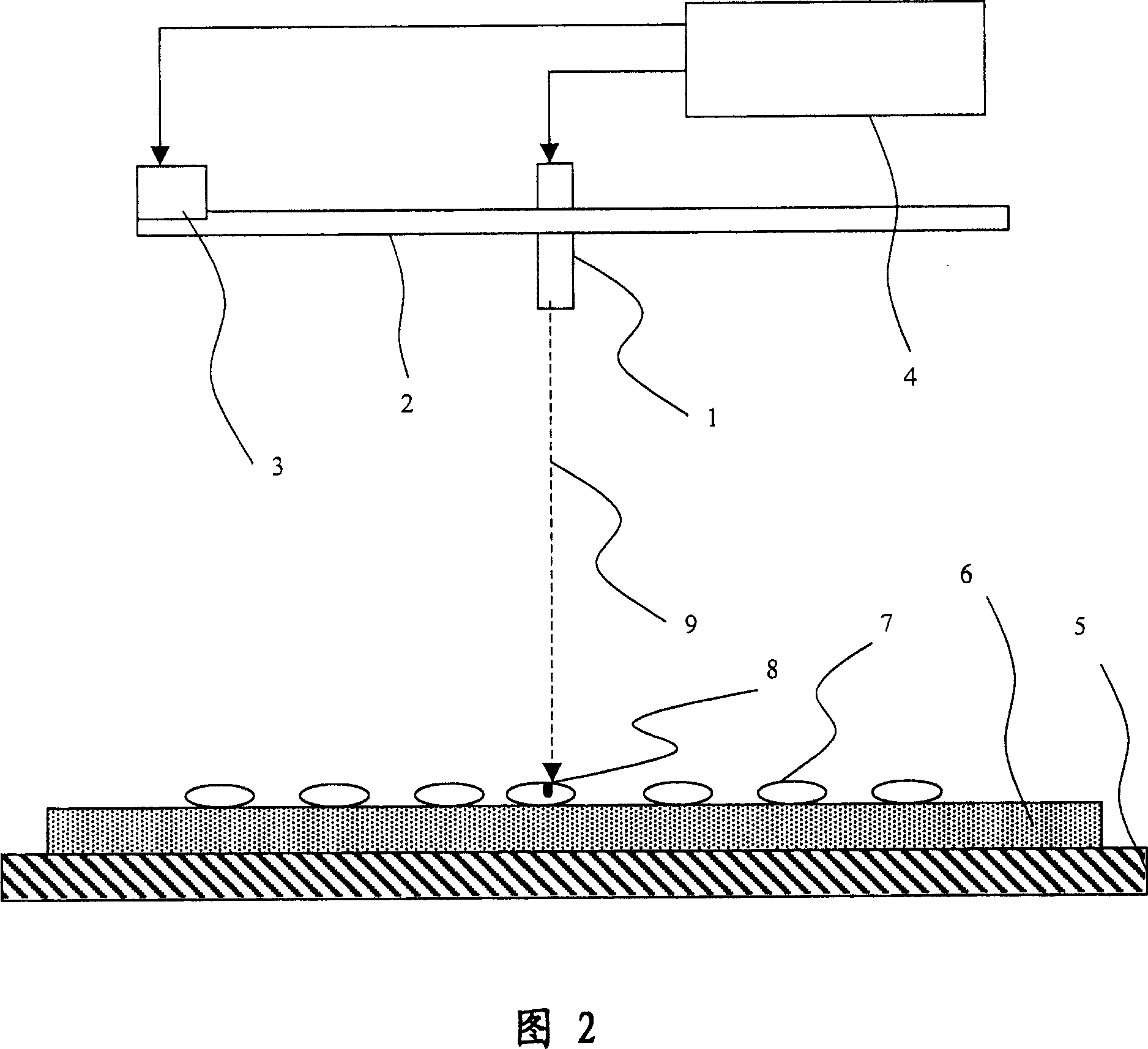

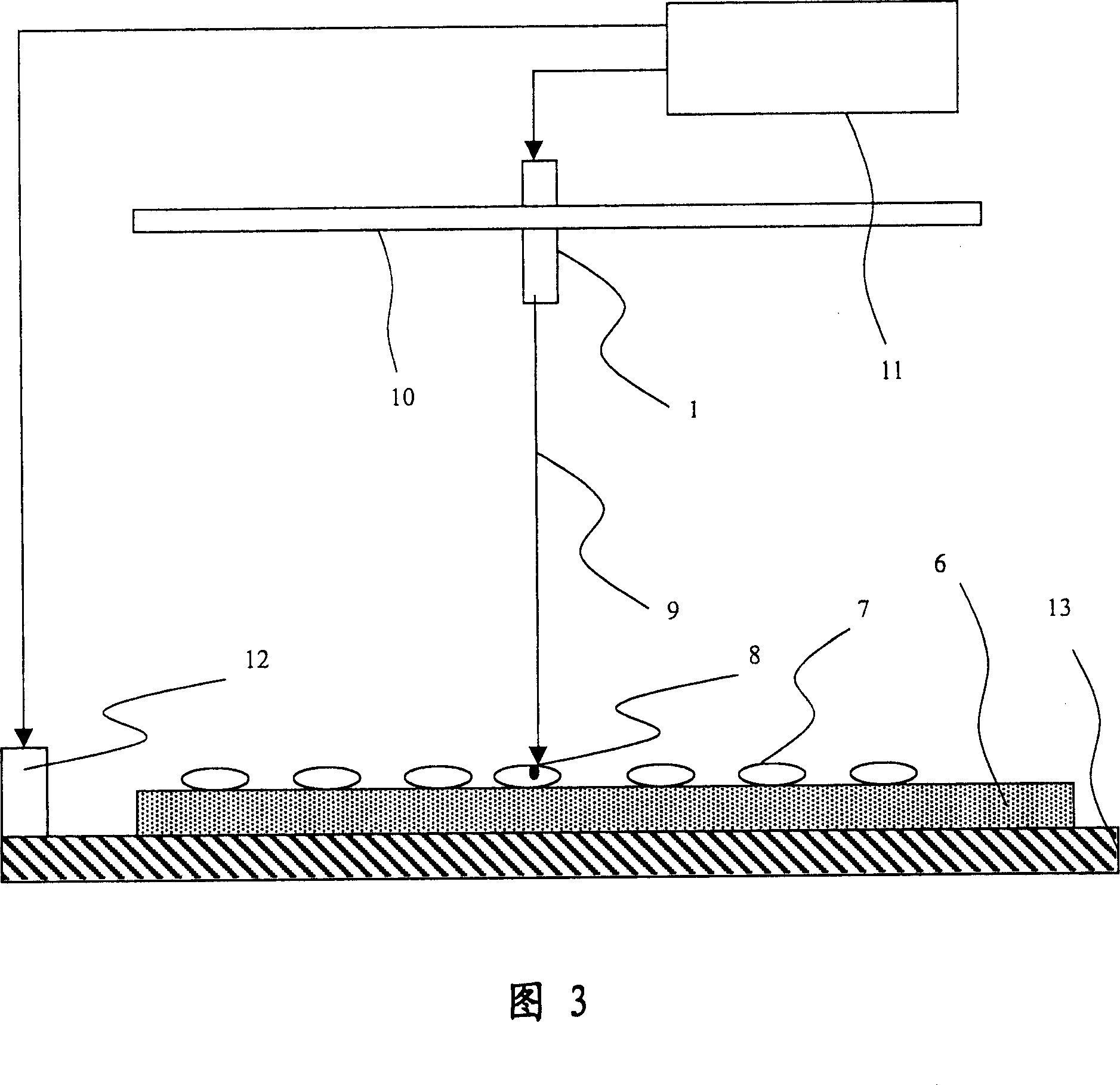

[0021] The operating principle of the present invention can be illustrated by Fig. 1: when decontamination, adjust the relative position of the laser emitting probe 1 and the circuit board 6, so that the contact point 7 is located directly below the laser emitting probe 1, and the laser emitting probe emits a specific The low-power laser of the frequency, the laser hits the stain 8 on the contact 7 along the normal direction 9, and the constituent material of the stain 8 absorbs the ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com