Method for treating quasi-prepressing groundwork of artificial island

A foundation treatment and artificial island technology, which is applied in the fields of water filling, foundation structure engineering, soil protection, etc., can solve the problems of shortening drainage distance, accelerating sinking speed, high cost of plastic drainage board and sand well, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

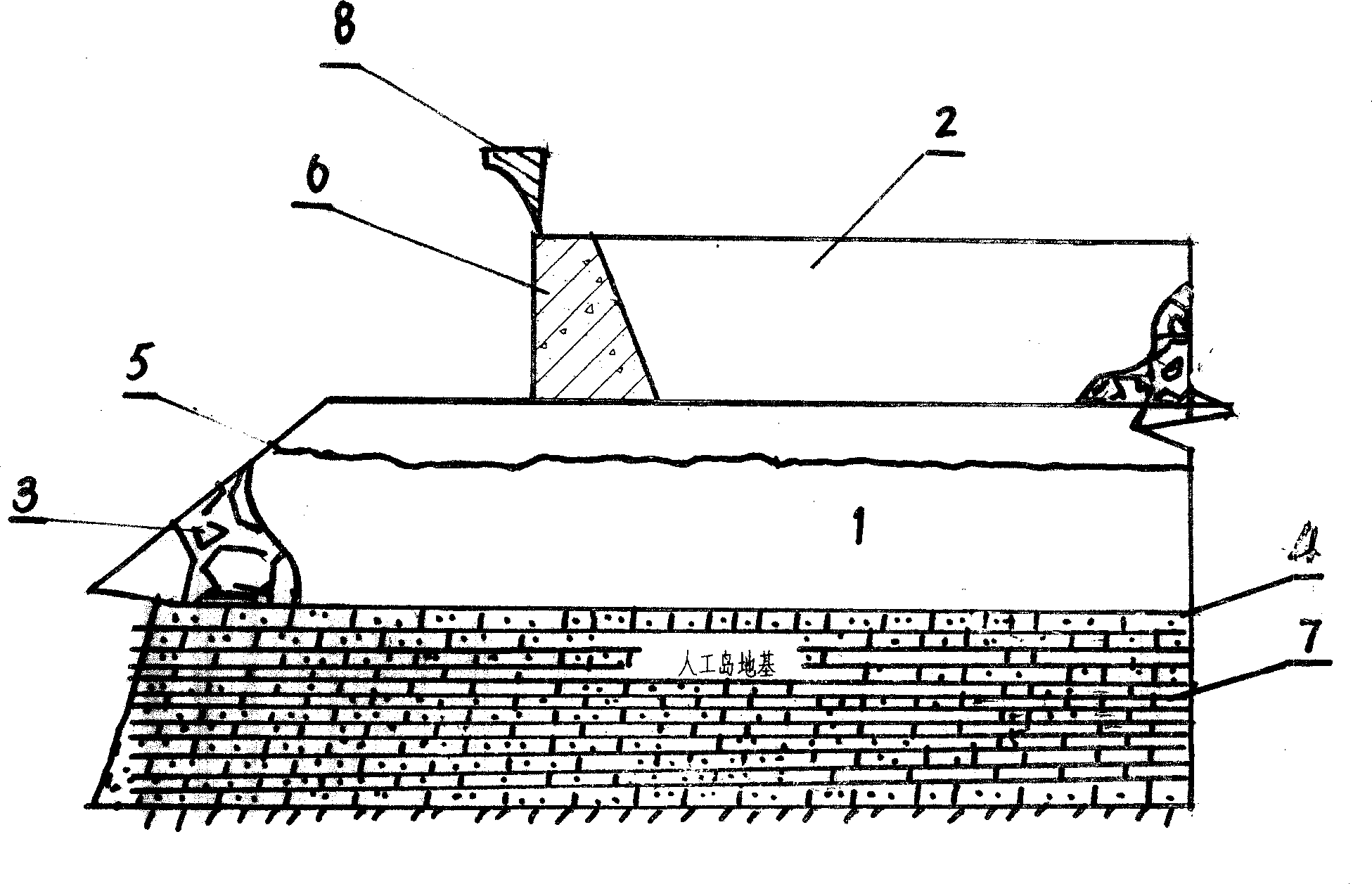

[0016] The height of the island block stone 3 above the foundation treatment surcharge layer 1 is 3.9 meters above the clay layer 7 in the seawater. After opening the sea, fill stones on the foundation treatment surcharge layer 1 and add mountain soil to form a secondary The total thickness of loading layer 2 is 7 meters.

Embodiment 3

[0018] There is an annular cement retaining wall 6 around the secondary loading layer 2, and the top surface of the retaining wall is provided with a wave wall 8 for preventing seawater intrusion and safety requirements.

[0019] After the related construction of the above-mentioned island body foundation, Liaohe Oilfield built 8 oil wells, a two-story living and office building and a well metering room on the island to carry out production and oil production, all of which were successful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com