Weather-resistant hydrogel roadbed operation period water content and dense state regulation and control method

A hydrogel roadbed, hydrogel technology, applied in roads, roads, infrastructure engineering and other directions, can solve problems such as inconvenient automatic moisture regulation of roadbed, improve bearing capacity and slope stability, reduce damage, reduce water effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

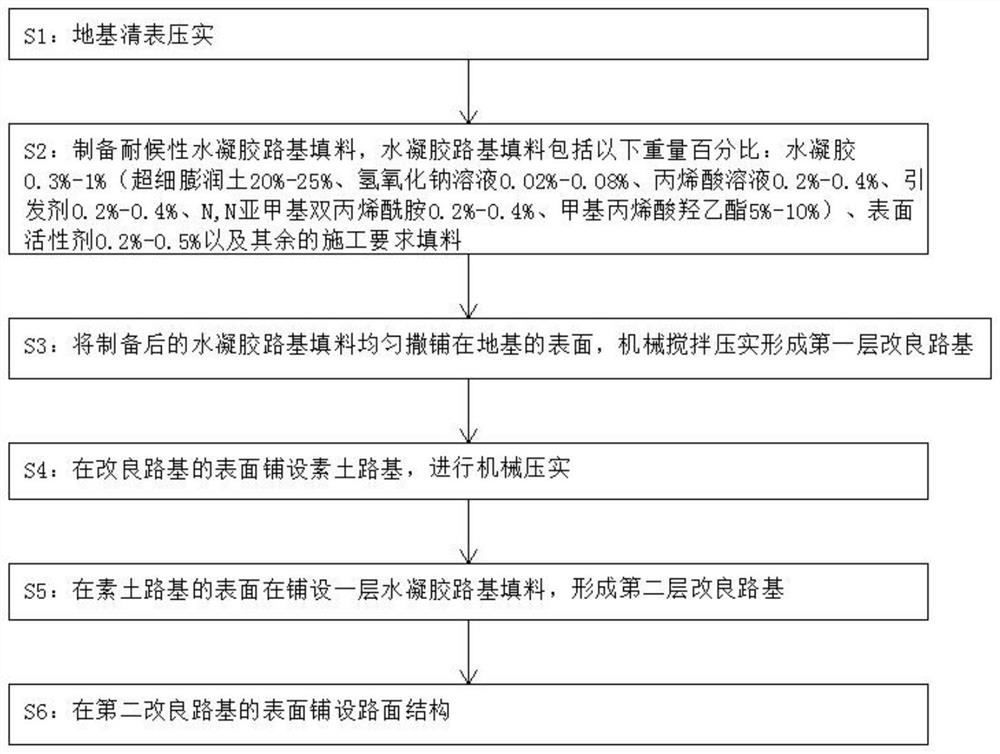

[0036] refer to figure 1 , based on the weather-resistant hydrogel roadbed moisture content and compact state control method during the operation period, including the following steps:

[0037] S1: Foundation cleaning and compaction;

[0038] S2: Preparation of hydrogel roadbed raw materials. The hydrogel roadbed raw materials include the following percentages by weight: 0.3% hydrogel (20% ultrafine bentonite, 0.02% sodium hydroxide solution, 0.2% acrylic acid solution, 0.2% initiator, N, N methylene bisacrylamide 0.2%, hydroxyethyl methacrylate 5%), surfactant 0.2% and the rest required construction materials:

[0039] S3: laying the prepared hydrogel roadbed raw material on the surface of the foundation to form the first layer of improved roadbed;

[0040] S4: lay plain soil roadbed on the surface of the improved roadbed, and carry out mechanical compaction;

[0041] S5: Lay a layer of hydrogel roadbed raw material on the surface of plain soil roadbed to form a second lay...

Embodiment 2

[0057] refer to figure 1 , based on the weather-resistant hydrogel roadbed moisture content and compact state control method during the operation period, including the following steps:

[0058] S1: Foundation cleaning and compaction;

[0059] S2: Preparation of hydrogel roadbed raw materials. The hydrogel roadbed raw materials include the following percentages by weight: 0.4% hydrogel (21% superfine bentonite, 0.03% sodium hydroxide solution, 0.22% acrylic acid solution, 0.22% initiator, N, N methylenebisacrylamide 0.22%, hydroxyethyl methacrylate 6%), surfactant 0.3% and the rest required construction materials:

[0060] S3: laying the prepared hydrogel roadbed raw material on the surface of the foundation to form the first layer of improved roadbed;

[0061] S4: lay plain soil roadbed on the surface of the improved roadbed, and carry out mechanical compaction;

[0062] S5: Lay a layer of hydrogel roadbed raw material on the surface of plain soil roadbed to form a second l...

Embodiment 3

[0078] refer to figure 1 , based on the weather-resistant hydrogel roadbed moisture content and compact state control method during the operation period, including the following steps:

[0079] S1: Foundation cleaning and compaction;

[0080] S2: Preparation of hydrogel roadbed raw materials. The hydrogel roadbed raw materials include the following percentages by weight: 0.5% hydrogel (23% ultrafine bentonite, 0.04% sodium hydroxide solution, 0.3% acrylic acid solution, 0.3% initiator, N, N methylenebisacrylamide 0.3%, hydroxyethyl methacrylate 7%), surfactant 0.23% and the rest required construction materials:

[0081] S3: laying the prepared hydrogel roadbed raw material on the surface of the foundation to form the first layer of improved roadbed;

[0082] S4: lay plain soil roadbed on the surface of the improved roadbed, and carry out mechanical compaction;

[0083] S5: Lay a layer of hydrogel roadbed raw material on the surface of plain soil roadbed to form a second lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com