Magnetization device for saving oil

A technology of magnetic conduction and magnetic concentration, which is applied in the direction of charging system, internal combustion piston engine, engine components, etc., can solve the problems of low magnetic force of magnetized fuel molecules, insufficient use of magnetic field, and inconspicuous accumulation of magnetic force lines, etc., to achieve structural Reasonable, smoke elimination and fuel saving are remarkable, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

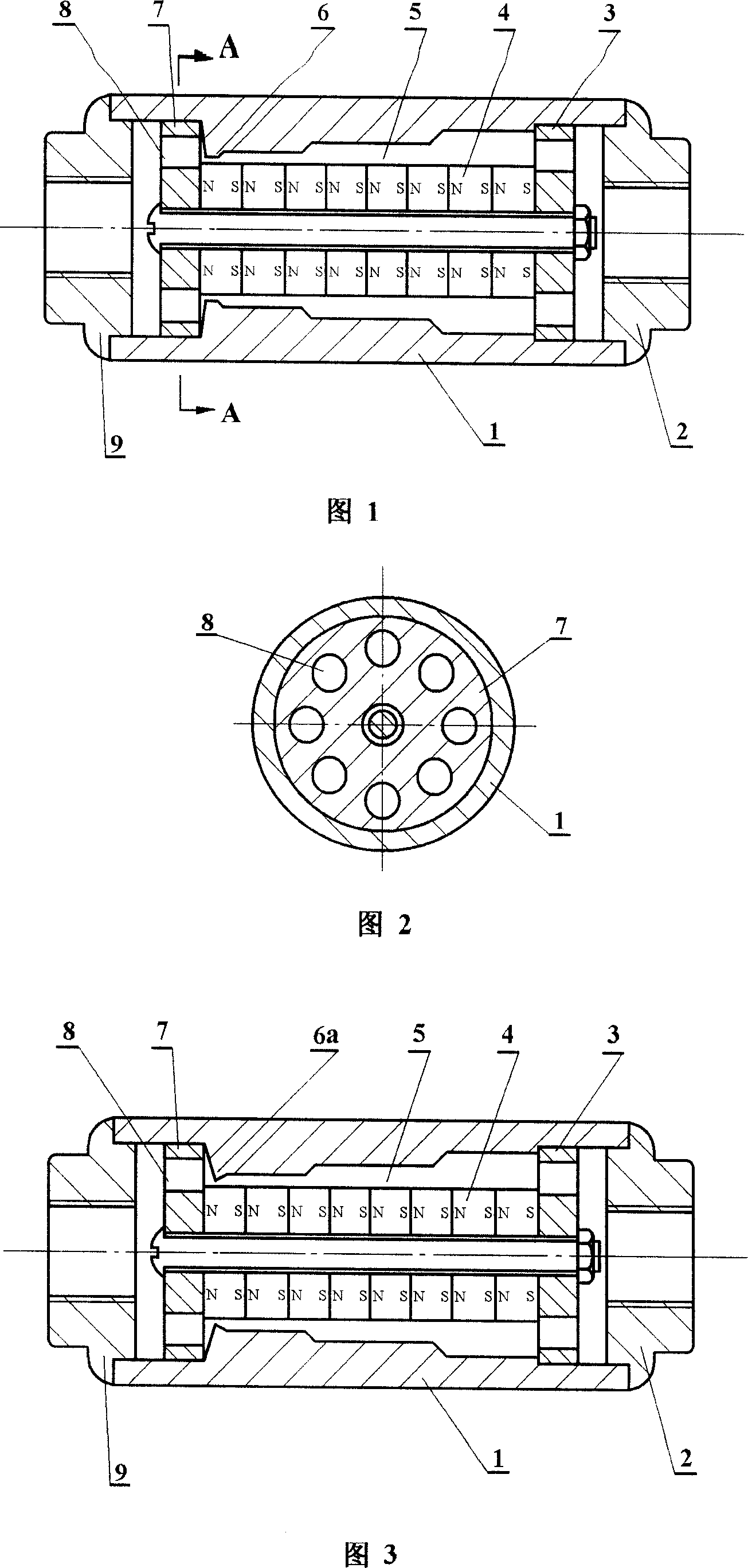

[0034] Embodiment 1: As shown in Fig. 1 and Fig. 2, the present invention is an improvement made on the basis of the existing magnetized fuel-saving device. Cylindrical magnetic conductive jacket 1, permanent magnet 4 fitted in magnetic conductive jacket 1, and ends made of low-carbon steel or industrial pure iron assembled on both ends of magnetic conductive jacket 1 through tight fit (or bonding or welding). Cover joints 2 and 9, in which the permanent magnet 4 is made of sintered NdFeB permanent magnet material into a cylinder and then magnetized in the axial direction, drilled and sliced to form a ring-shaped sheet structure, so that the surface field of each permanent magnet is greater than 3000 gauss. Take 8 pieces of the above-mentioned permanent magnets, and stack the different poles of each piece of permanent magnets, and use a non-magnetic metal bolt, a magnetic plate 7 and a positioning plate 3 to fix the above-mentioned stacked permanent magnets on the magnetic p...

Embodiment 2

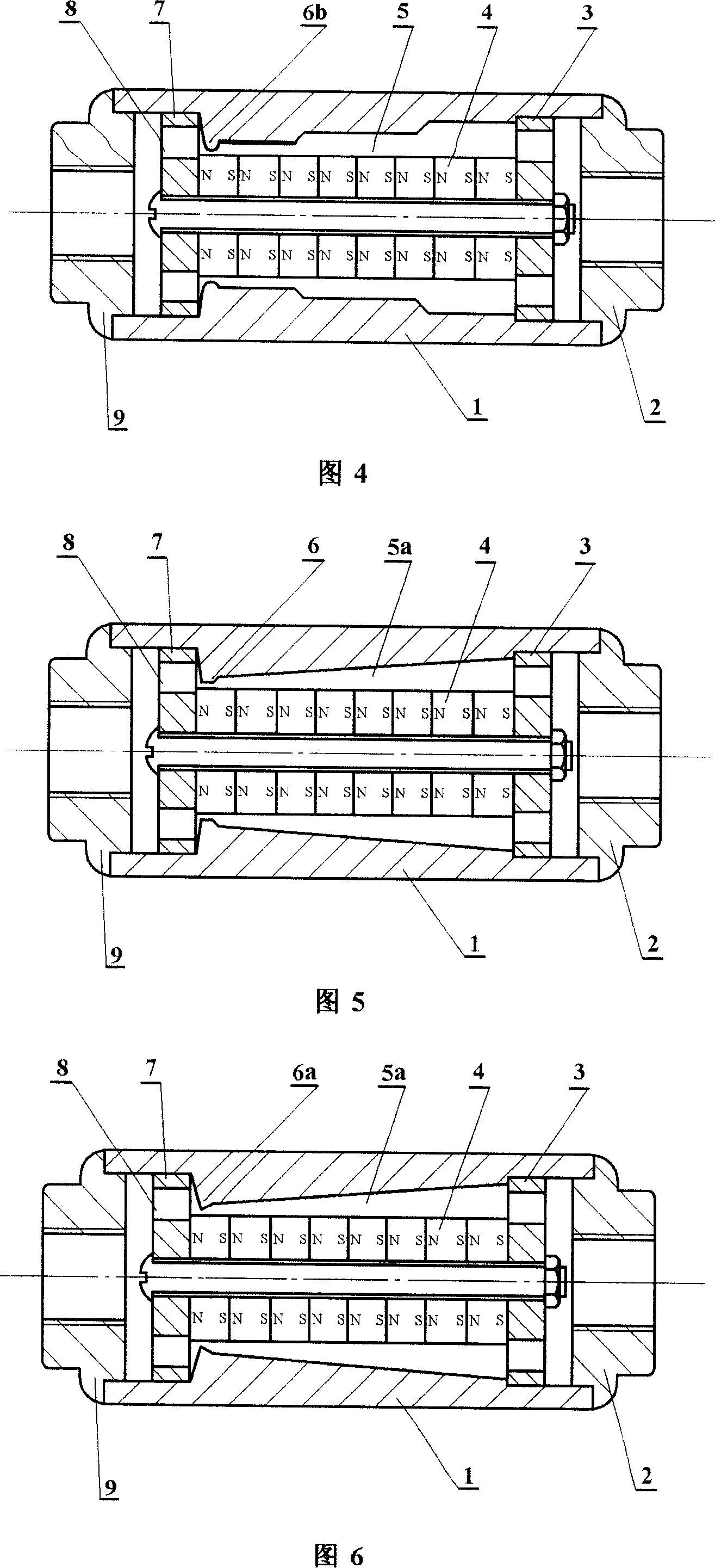

[0035] Embodiment 2: As shown in FIG. 3 , the difference between this embodiment and Embodiment 1 is that the axial cross-sectional shape of the magneto-resistance current ring 6 a is a triangle.

Embodiment 3

[0036] Embodiment 3: As shown in FIG. 4 , the difference between this embodiment and Embodiment 1 is that the cross-sectional shape of the magneto-resistance current ring 6 b is semicircular (irregularly curved).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com