Double suction microminiature type vane pump with no spindle drive

An ultra-small vane pump technology, which is applied to the components, pumps, and pump devices of pumping devices for elastic fluids. It can solve the problems of reduced hydraulic efficiency and difficulty in optimizing and controlling the flow of ultra-small vane pumps. Axial load, elimination of stagnation zone, reduction of the effect of axial water thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

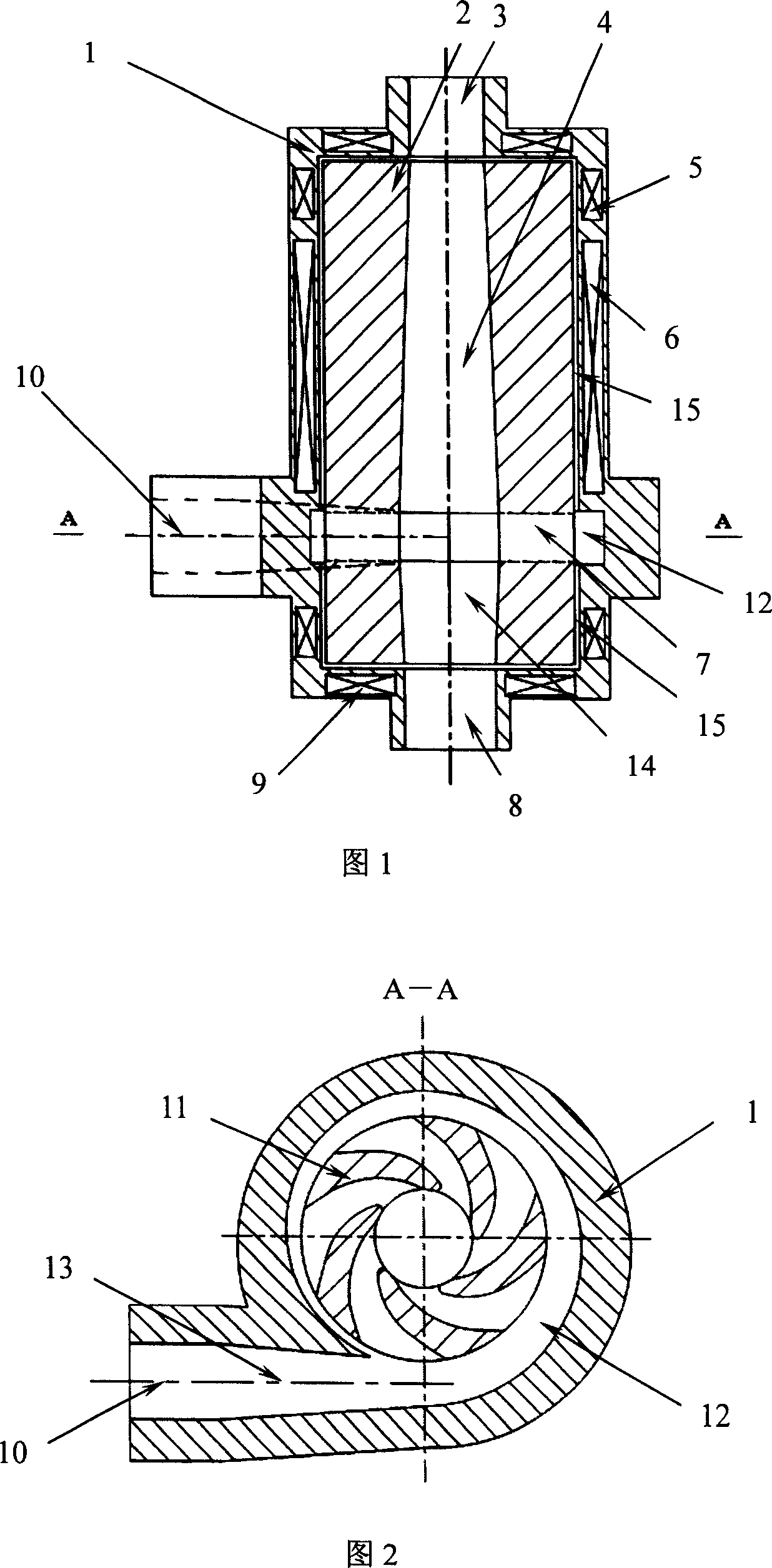

[0014] Principle of the present invention, structure are further described below in conjunction with accompanying drawing

[0015] Figure 1 is a main sectional view of a double-suction shaftless driven ultra-small vane pump. The ultra-small vane pump includes a pump body 1 , a pump first suction port 3 , a pump second suction port 8 , a pump impeller 7 , a motor rotor 2 , a motor stator 6 , a pressurized water chamber 12 and a pump outlet 10 .

[0016] The pump impeller 7 is integrated with the motor rotor 2, and the center of the motor rotor 2 is provided with a first impeller inlet 4 and a second impeller inlet 14, which communicate with the first pump suction port 3 and the second pump suction port 8 respectively. A pressurized water chamber 12 is provided on the outer periphery of the pump impeller, and a diffusion section 13 is provided between the pump outlet 10 and the pressurized water chamber 12 . Wherein the first suction port 3 of the pump, the second suction port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com