Bolt falling preventive structure and hold ring

A technology for retaining rings and bolts, applied in the directions of bolts, nuts, connecting components, etc., can solve the problems of increasing particles, increasing production costs, increasing component parts, etc., and achieves the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

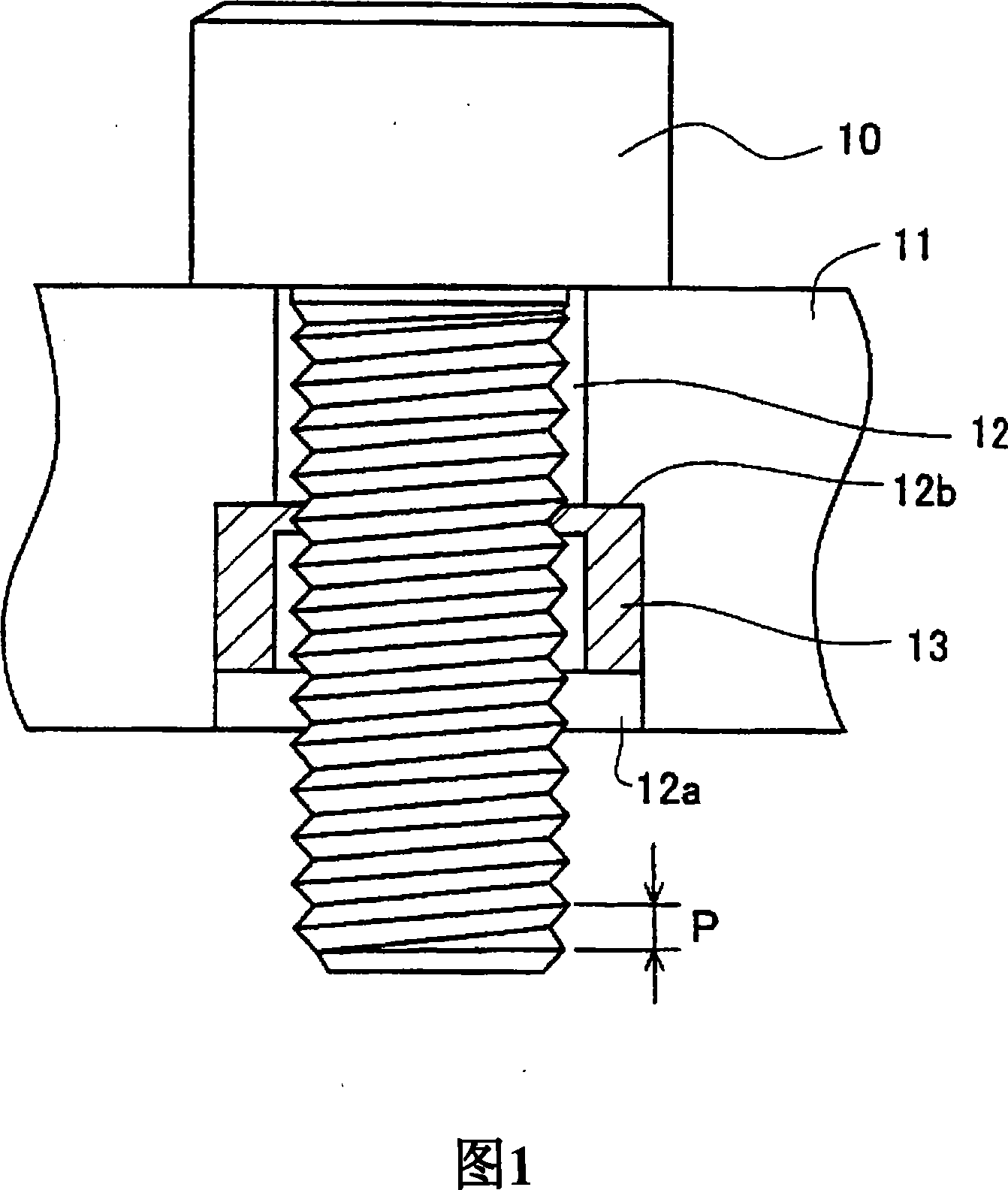

[0087] Fig. 1 is a front partial cross-sectional view of a bolt drop-off prevention mechanism and a retaining ring of the present invention, specifically, a module of a gas integration unit used in a semiconductor manufacturing device, that is, an on-off valve, a flow meter, and a fixed body. A cross-sectional view of a plurality of threaded through-holes 12 serving as mounting holes on a mounting flange portion 11 of a mass flow controller or the like. By inserting the main body fixing bolts 10 into the threaded through holes 12 (hereinafter referred to as the threaded through holes 12 ) serving as mounting holes, the above-mentioned modules are mounted on an unillustrated mounting rail or flow path block.

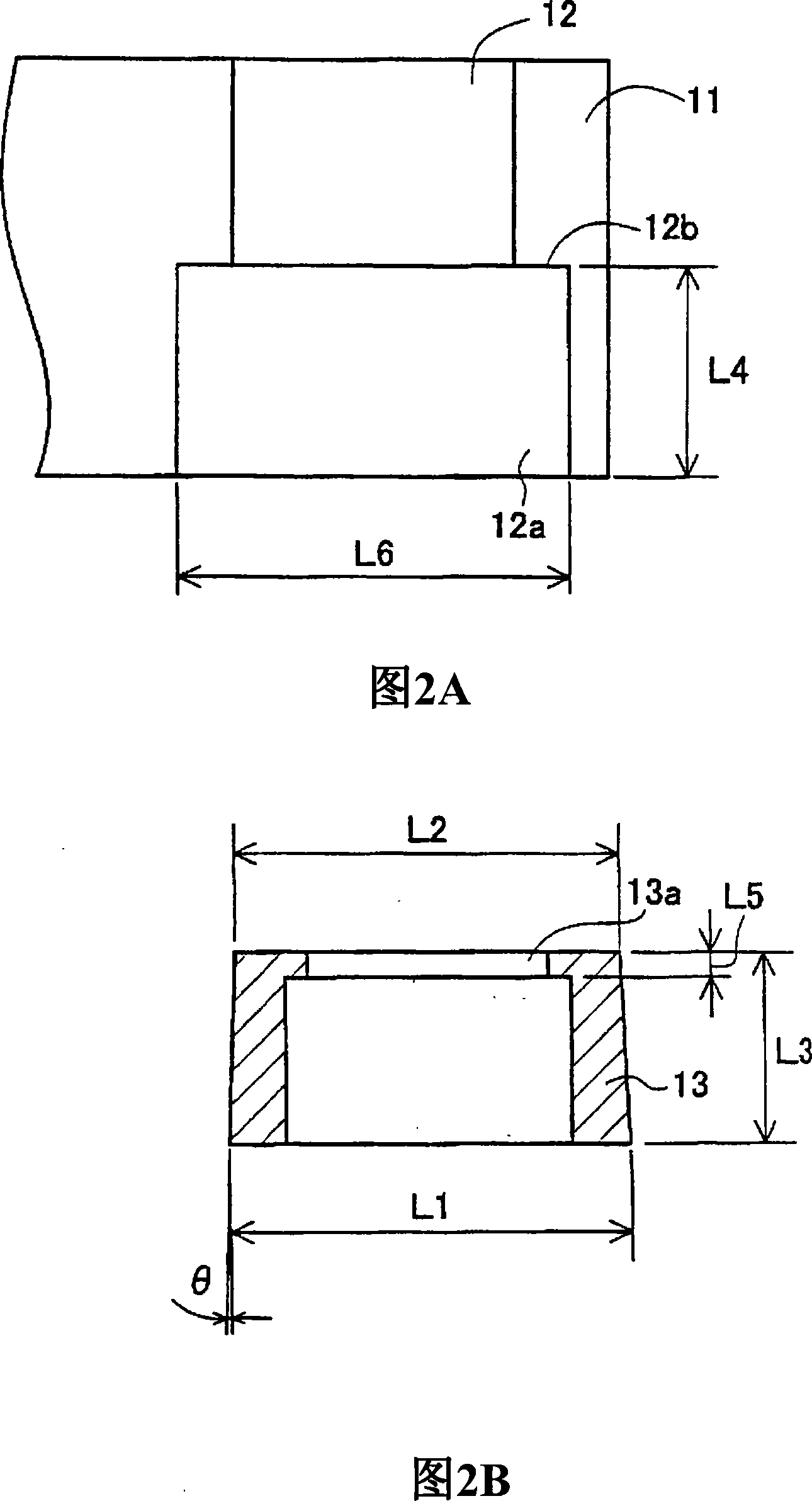

[0088] FIG. 2 is a partial detailed view and a component view thereof. A plurality of threaded through holes 12 as shown in FIG. 2A are provided on the mounting flange 11 of the on-off valve and the mass flow controller of the module as the gas integration unit, and on th...

no. 2 example

[0099] Next, a second embodiment of the present invention will be described.

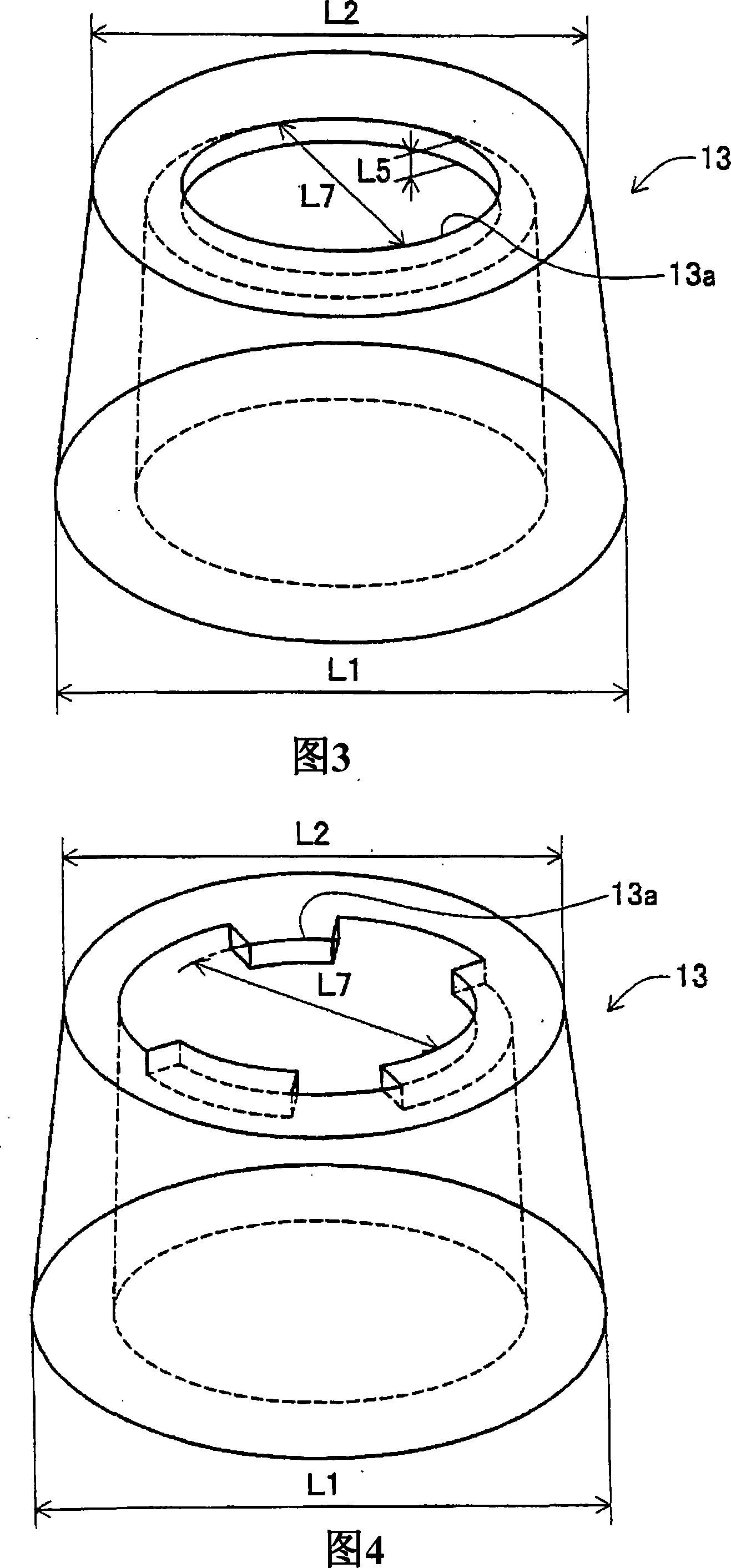

[0100] Figure 3 shows a perspective view of the first embodiment; Figure 4 shows a perspective view of the second embodiment.

[0101] The retaining ring 13 of the second embodiment has substantially the same outer shape as the retaining ring 13 of the first embodiment, but the shape of the portion of the bolt engaging portion 13a is different. The bolt engaging portion 13a of the second embodiment is not a simple circle, but has cutouts at three places, and the contact area between the bolt engaging portion 13a and the main body fixing bolt 10 is reduced. That is, the bolt engaging portion 13 a is constituted by three substantially trapezoidal protrusions, and one side of the substantially trapezoidal protrusions is in diametric contact with the bottom of the external thread portion of the main body fixing bolt 10 . In addition, the thickness L5 of the bolt engaging portion 13a is the same as that...

no. 3 example

[0111] Next, a third embodiment of the present invention will be described.

[0112] FIG. 5 shows a top view of the third embodiment; FIG. 6 shows a cross-sectional view of the third embodiment.

[0113] In the third embodiment, although the holding ring 13 of the first embodiment has substantially the same substantially cylindrical outer shape, the bolt engaging portion 13a serving as a member for holding the main body fixing bolt 10 is different from that of the second embodiment. Unlike the bolt engaging portion 13 a of the example, the width of the thickness L5 is larger than the pitch of the bolts of the main body fixing bolts 10 . In the third embodiment, the thickness L5 of the bolt engaging portion 13 a is set to be at least twice the pitch of the main body fixing bolt 10 .

[0114] The shape of the bolt engaging portion 13a is not a simple circle, but three notches are provided, and the contact area between the bolt engaging portion 13a and the main body fixing bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com