Pressurizing machine

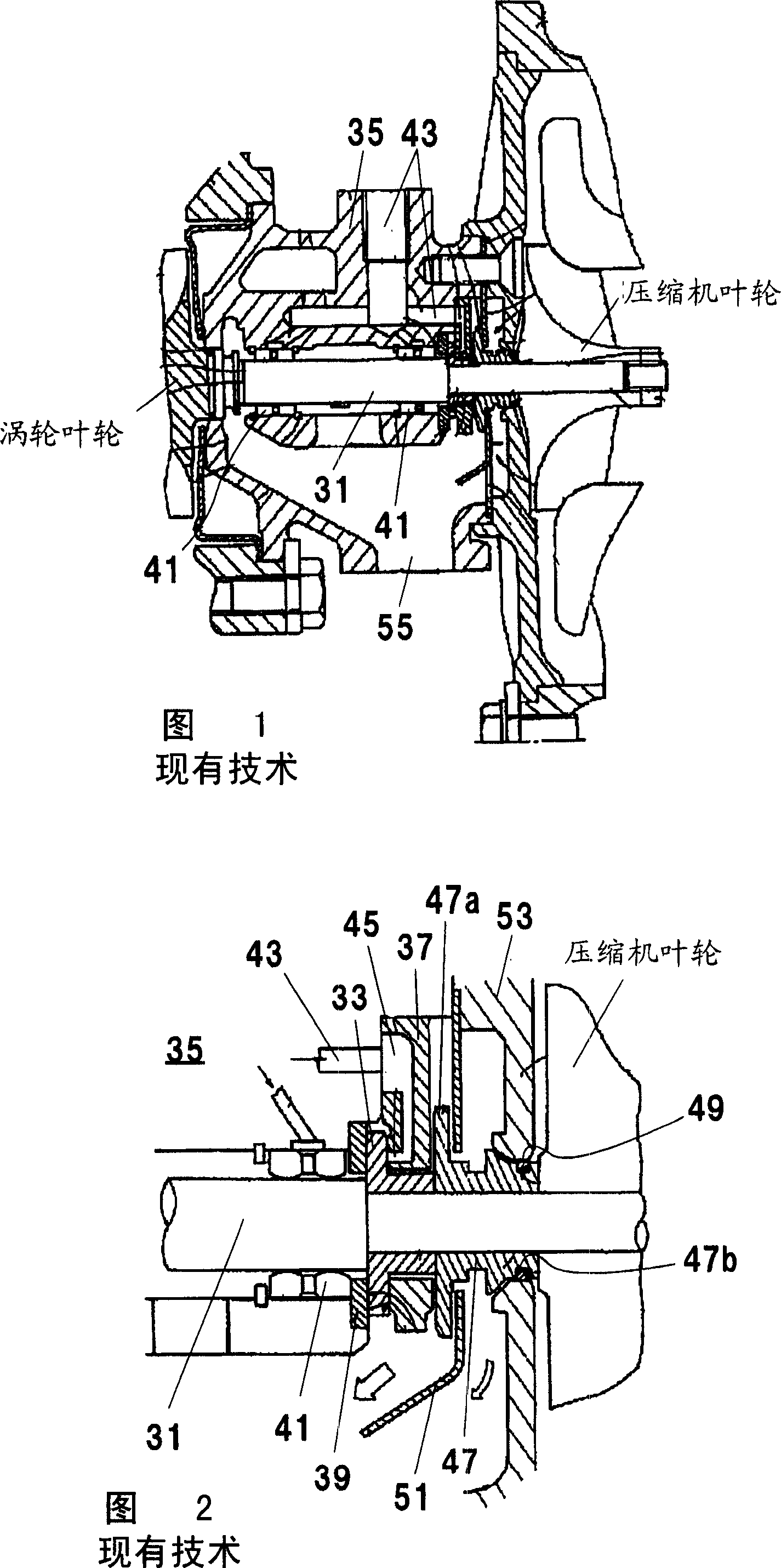

一种增压机、压缩机的技术,应用在机械设备、发动机元件、燃气轮机装置等方向,能够解决密封部件作业性差、不方便等问题,达到提高密封性、简单安装作业的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

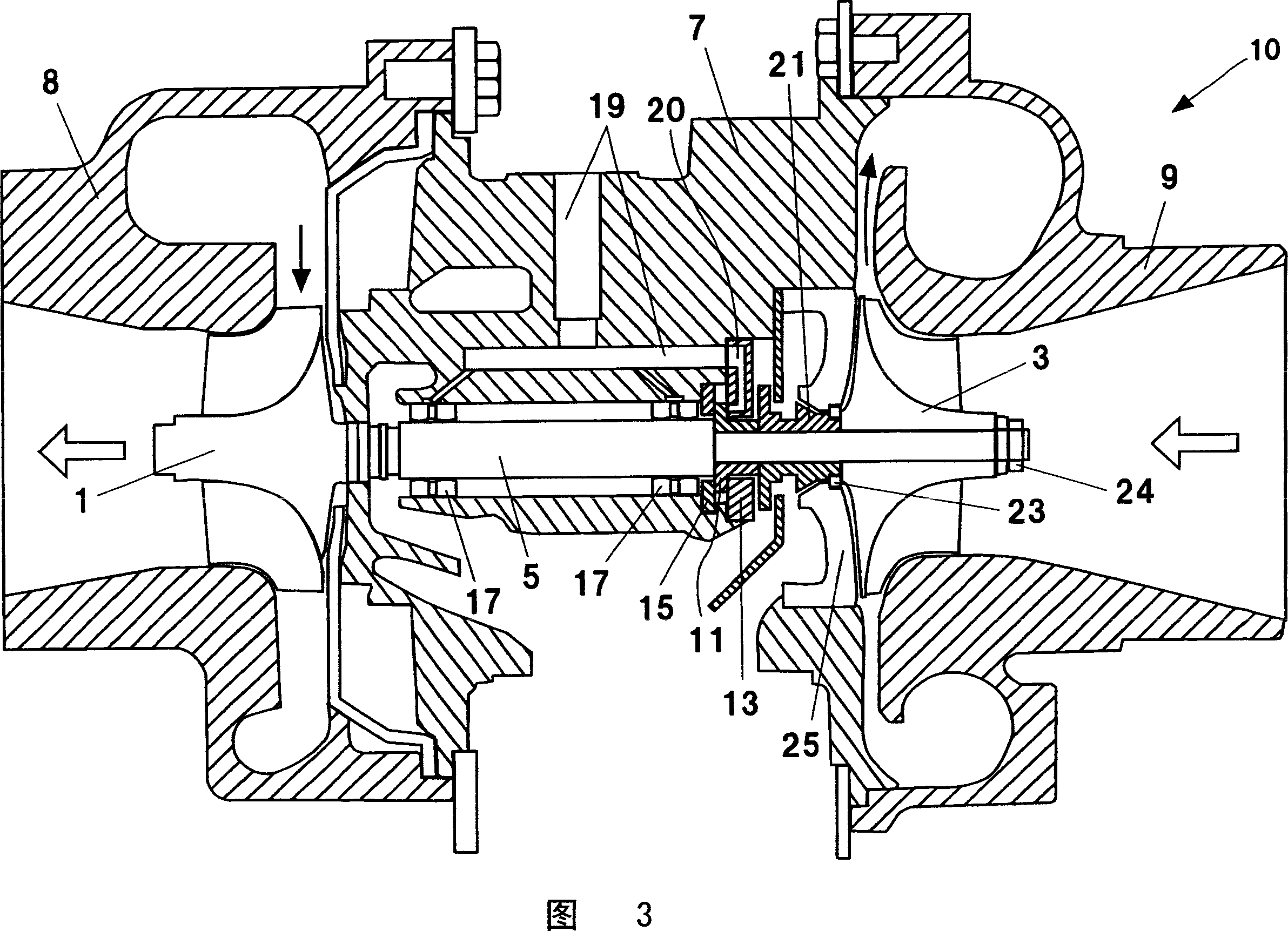

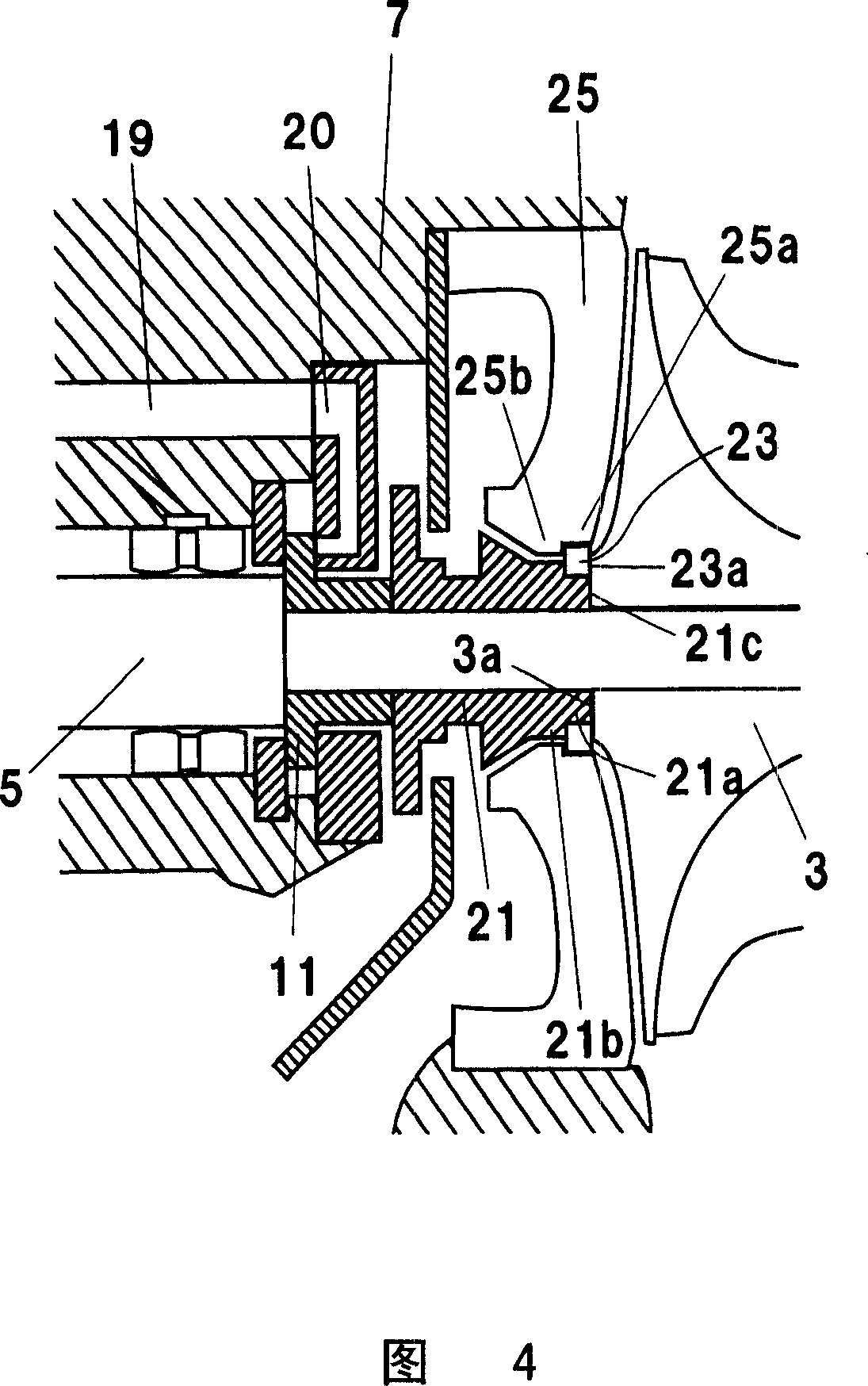

[0053] Preferred embodiments of the present invention are described with reference to the drawings. In addition, the same code|symbol is used for the common part in each figure, and a repeated description is abbreviate|omitted.

[0054] 3 is a longitudinal sectional view of the supercharger according to the embodiment of the present invention cut along the axial direction, showing the overall configuration of the supercharger. As shown in FIG. 3 , the supercharger 10 according to the present embodiment includes: a turbine impeller 1 driven to rotate by exhaust gas; a compressor impeller 3 driven to compress air by rotation of the turbine impeller 1; connected to the turbine impeller 1 and the rotating shaft 5 of the compressor impeller 3; the housing 7 of the bearing structure that rotatably supports the rotating shaft 5 is assembled inside.

[0055] In the example of FIG. 3 , the housing 7 is a bearing housing separated from the turbine housing 8 housing the turbine wheel 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com