Process and arrangement for filling a high pressure gas container with liquefied gas under hydrostatic pressure

A technology for liquefied gas and gas containers, which is applied to the methods of container discharge, equipment loaded into pressure vessels, and equipment discharged from non-pressure vessels, etc., which can solve problems such as high productivity, complicated methods, and complicated precise measurement of liquefied gases. Problems, to avoid pressure fluctuations, high measurement accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

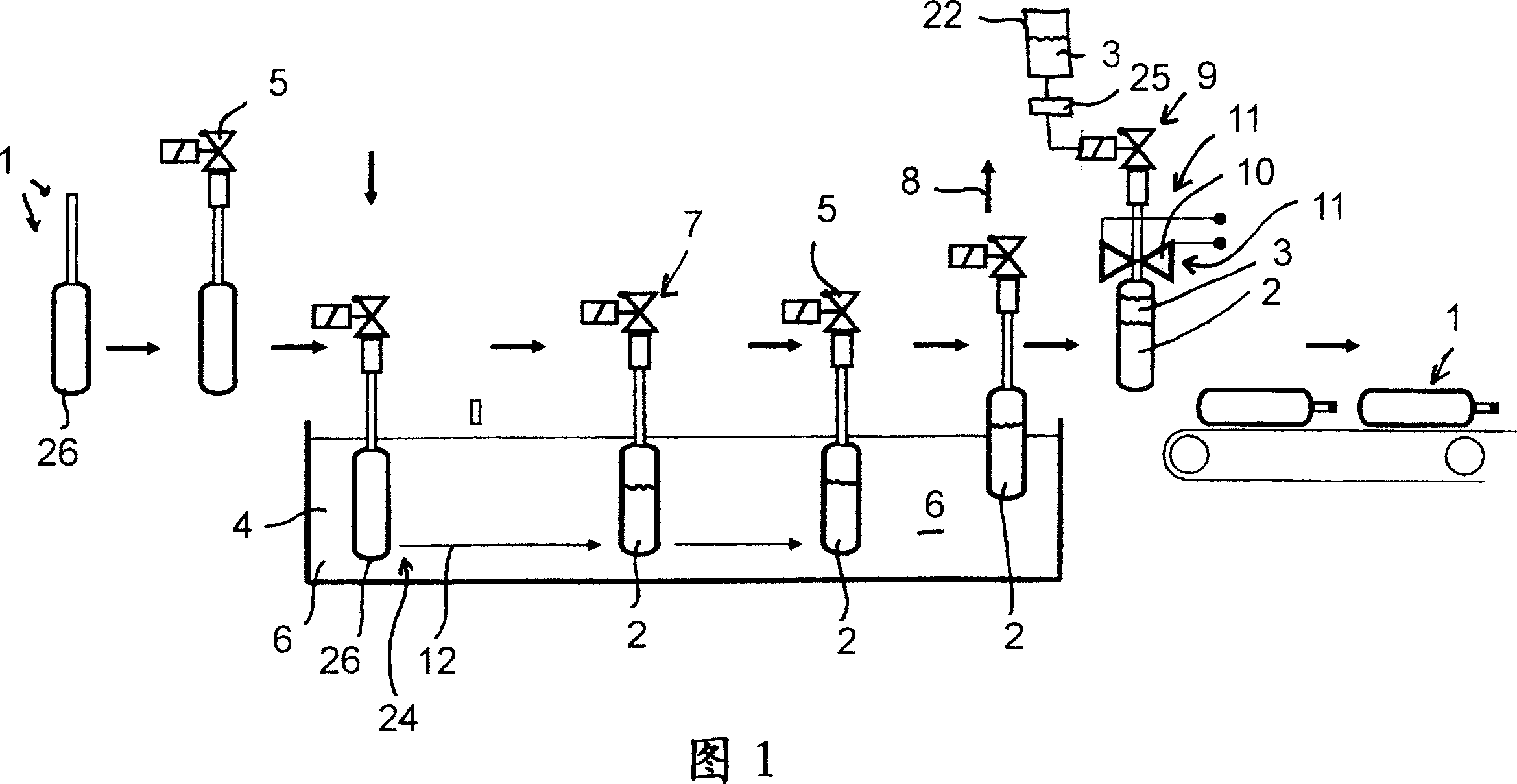

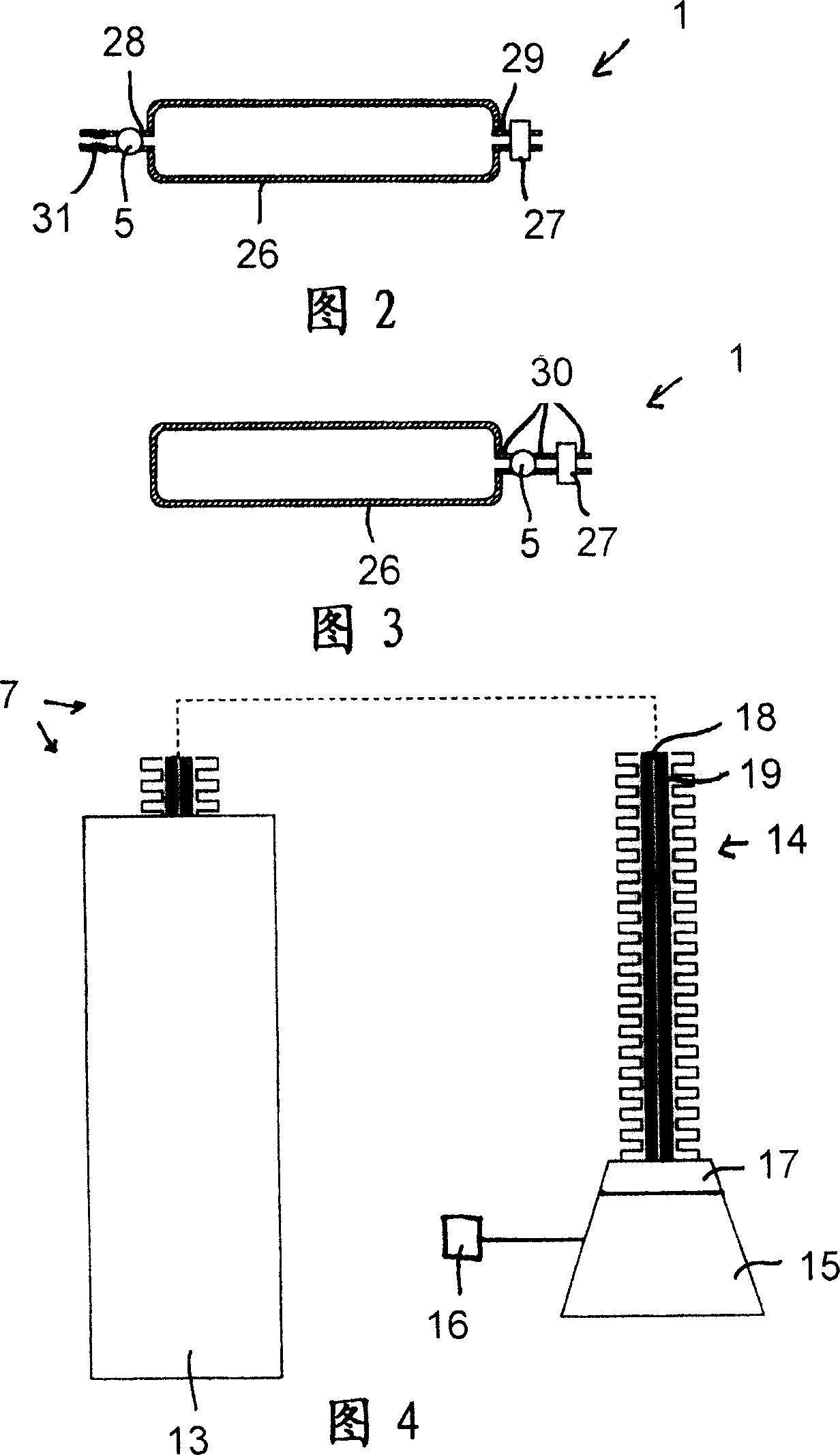

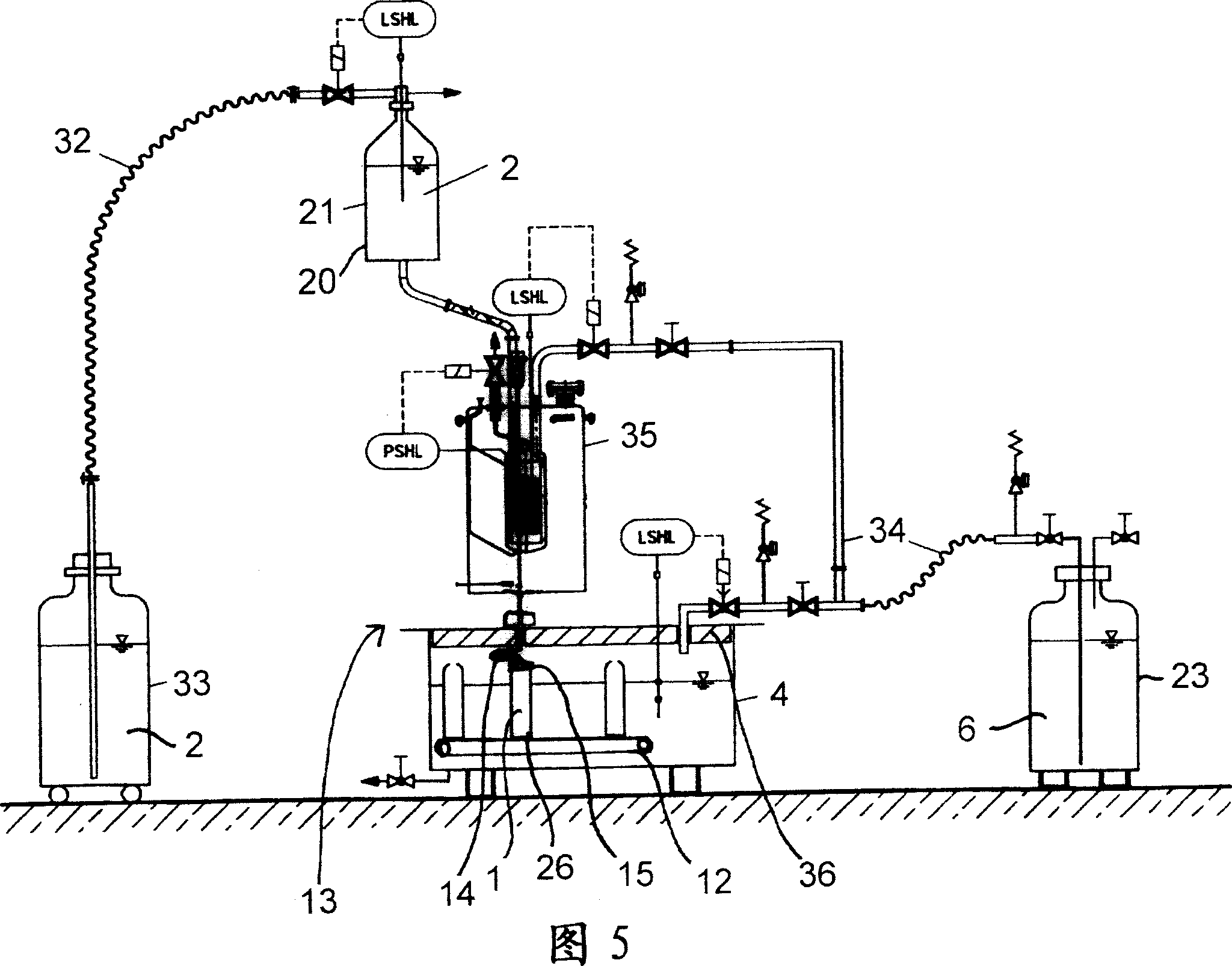

[0066] Figure 1 schematically shows a two-step method for filling a high-pressure gas container 1 with a first gas 2 and a second gas 3 using a supply unit 7 and an introduction unit 9 for supplying the first gas to the gas container 1. The gas 2 is used for introducing the second gas 3 into the gas container 1 by the introduction unit 9. The gas container 1 includes a container body 26 for receiving the first gas 2 and the second gas 3 and connected to the auxiliary valve 5. The gas container 1 is connected to the cooling tank 4 containing the third gas 6, and the third gas is liquefied to pre-cool the gas container 1 to 86°K. The third gas 6 is liquid nitrogen, which is kept at a low pressure in the cooling tank 4 to achieve 86°K in the cooling tank 4. This pre-cooling is performed using a pre-cooling unit 24 that at least partially immerses the gas container 1 in the cooling tank 4. The gas container 1 is then transported to the supply unit 7 by the transport mechanism 12, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap