Luminescence module and surface light source device

A technology for light-emitting modules and surface light sources, which is applied in identification devices, optics, optical components, etc., and can solve problems such as high cost, large mixing space, and poor luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

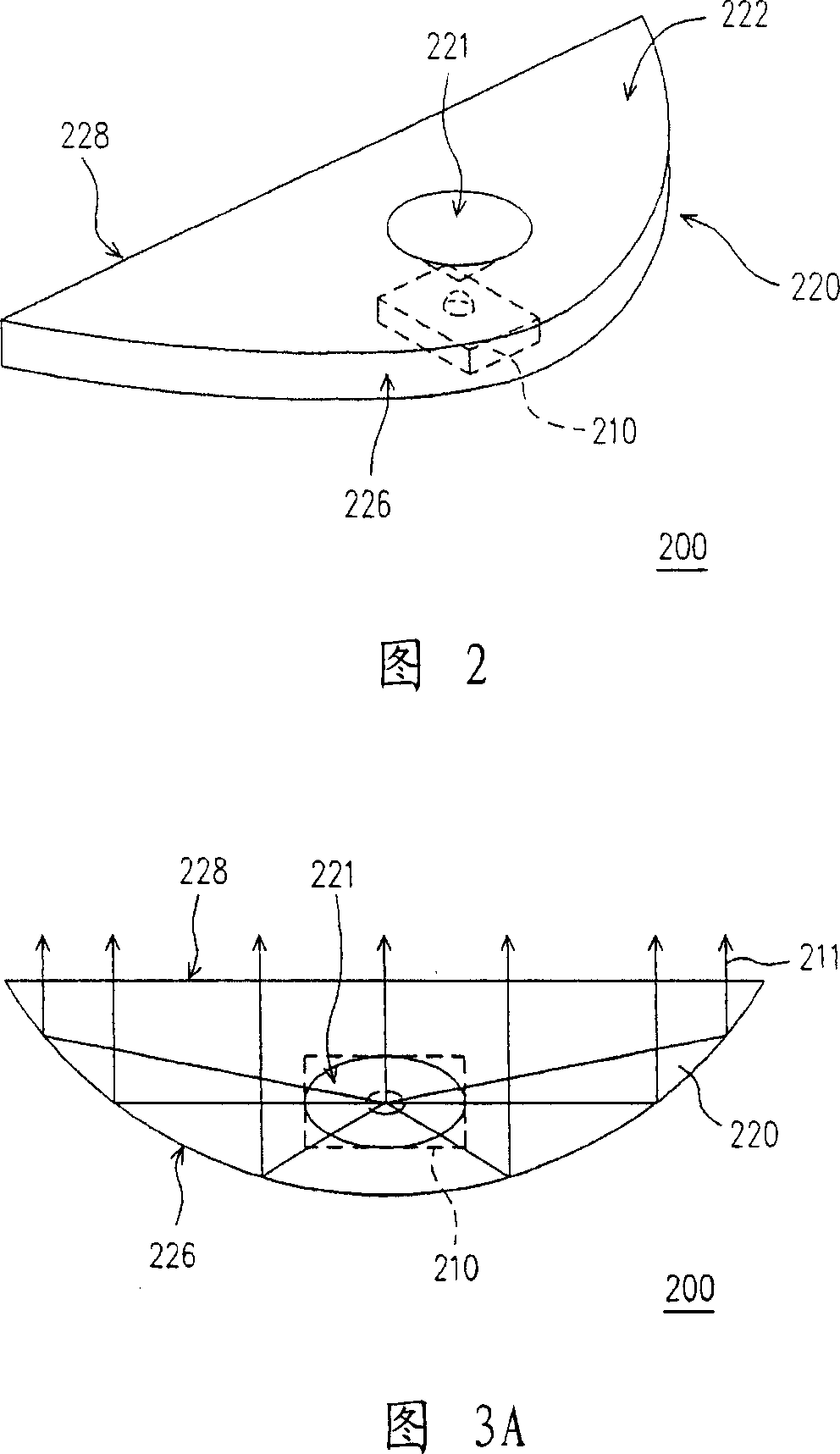

[0053] Please refer to FIG. 2 , FIG. 3A and FIG. 3B , FIG. 2 is a perspective view of the light emitting module according to the first embodiment of the present invention, FIG. 3A is a top view, and FIG. 3B is a structural cross-sectional view. The light emitting module 200 of the first embodiment of the present invention includes a light source group 210 and a light guide 220 . The light source group 210 is suitable for providing a light 211 , and the light guide 220 is disposed above the light source group 210 . Wherein, the light guide 220 has a top surface 222 and a light incident surface 224 opposite to each other, and a first reflective surface 226 and a light exit surface 228 opposite to each other, and the first reflective surface 226 and a light exit surface 228 are respectively connected to Between the top surface 222 and the light incident surface 224 , the two ends of the first reflective surface 226 are, for example, connected to the two ends of the light exit sur...

no. 2 example

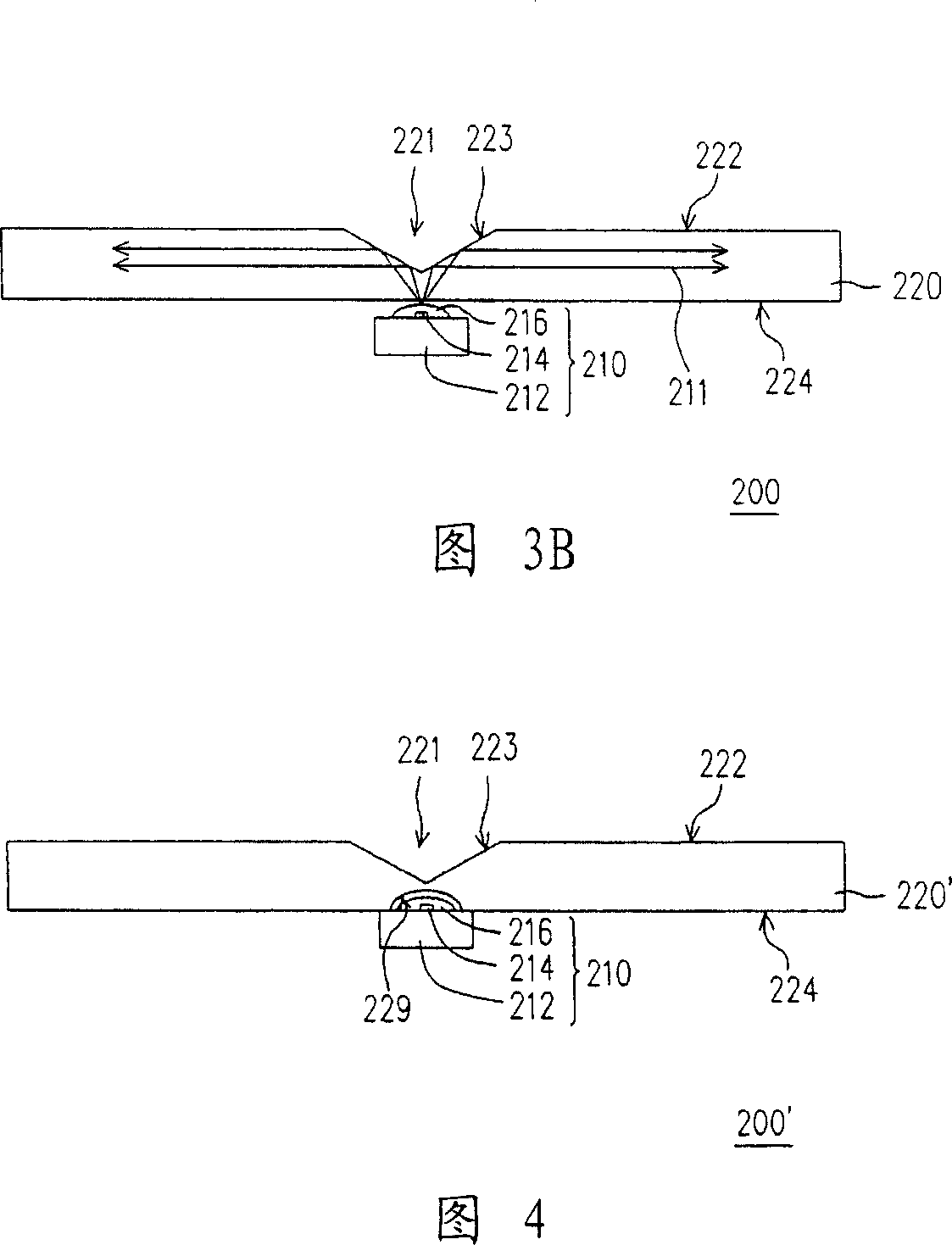

[0061] Please refer to FIG. 4 , which is a structural sectional view of a light emitting module according to a second embodiment of the present invention. The light emitting module 200' of the second embodiment is similar to the above light emitting module 200, except that the light incident surface 224 of the light guide member 220' of the light emitting module 200' has a second recess 229, which is opposite to the first recess 221, The light source group 210 is embedded in the second recess 229 , so that the alignment between the light source group 210 and the light guide member 220 ′ is facilitated, and the assembly time is reduced.

no. 3 example

[0063] In this embodiment, the above-mentioned light emitting modules 200, 200' of the first embodiment and the second embodiment are applied to a surface light source device, and the surface light source device 300 includes a light guide plate 310 and a plurality of the above light emitting modules 200. The light emitting modules 200 are disposed on one side (as shown in FIG. 5 ) or both sides (as shown in FIG. 6 ) of the light guide plate 310, and the light 211 emitted from the light exit surface of the light guide member 220 of each light emitting module 200 is incident on the light guide plate. 310, and the light guide plate 310 is suitable for converting these light rays 211 into a surface light source with uniform brightness. The light guide 220 of each light emitting module 200 can be a separate part or integrally formed, and the light guide 220 and the light guide plate 310 of each light emitting module 200 can also be a separate part or integrally formed, when the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com