Clamping apparatus

A clamping device and clamping bolt technology, applied in the direction of positioning device, clamping, tool clamp, etc., can solve the problems of increasing the total cost of the clamping system, mechanical damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

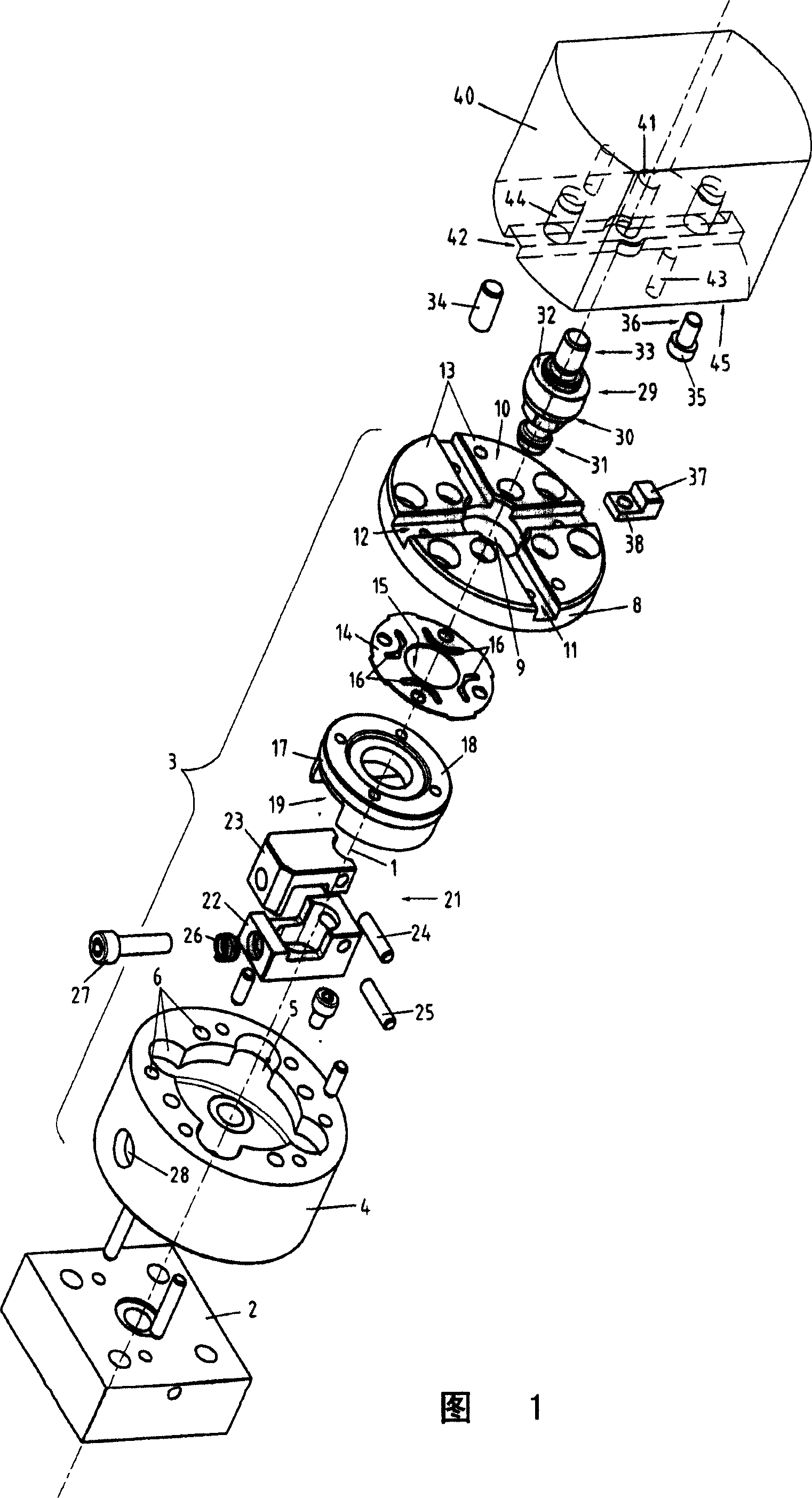

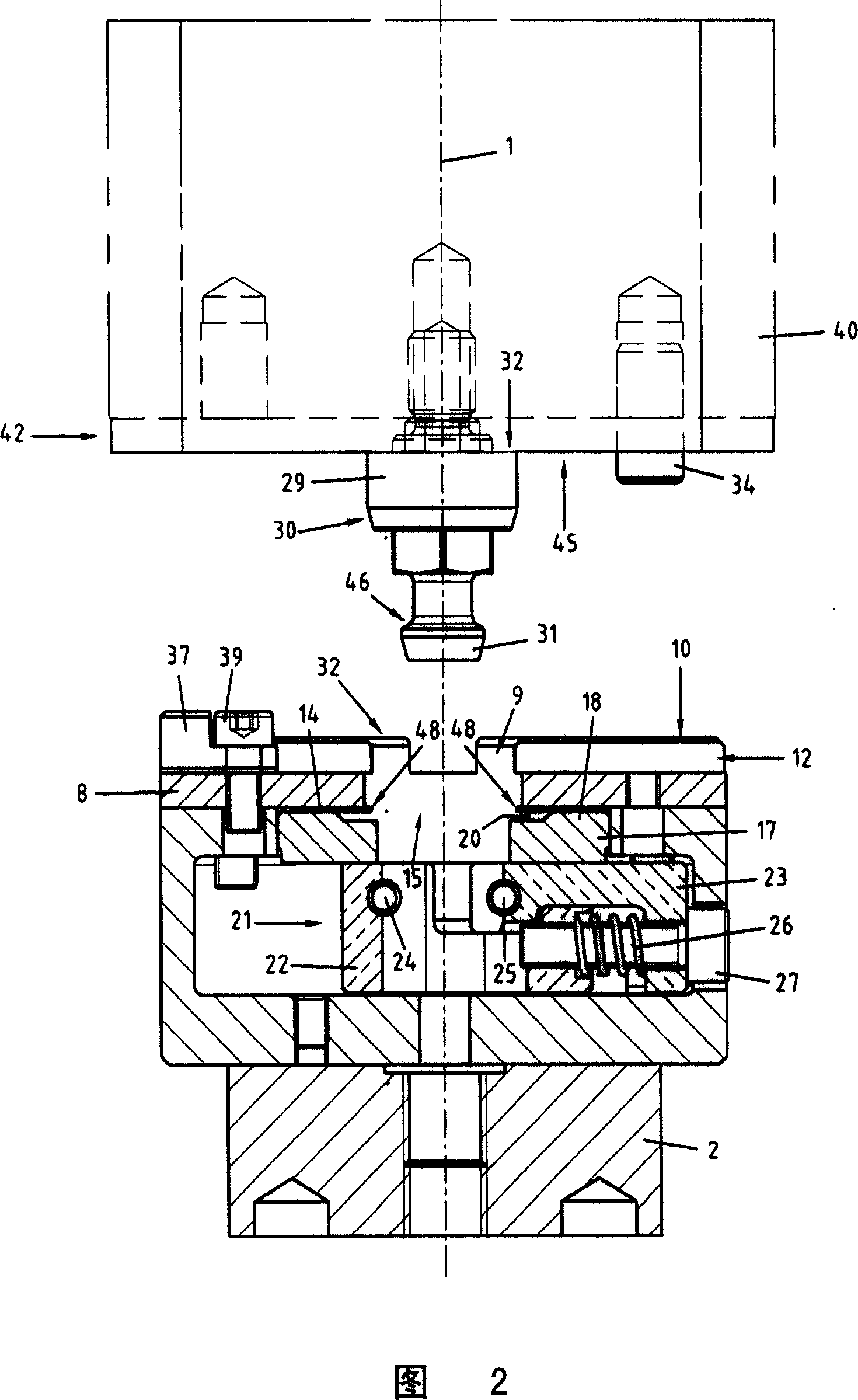

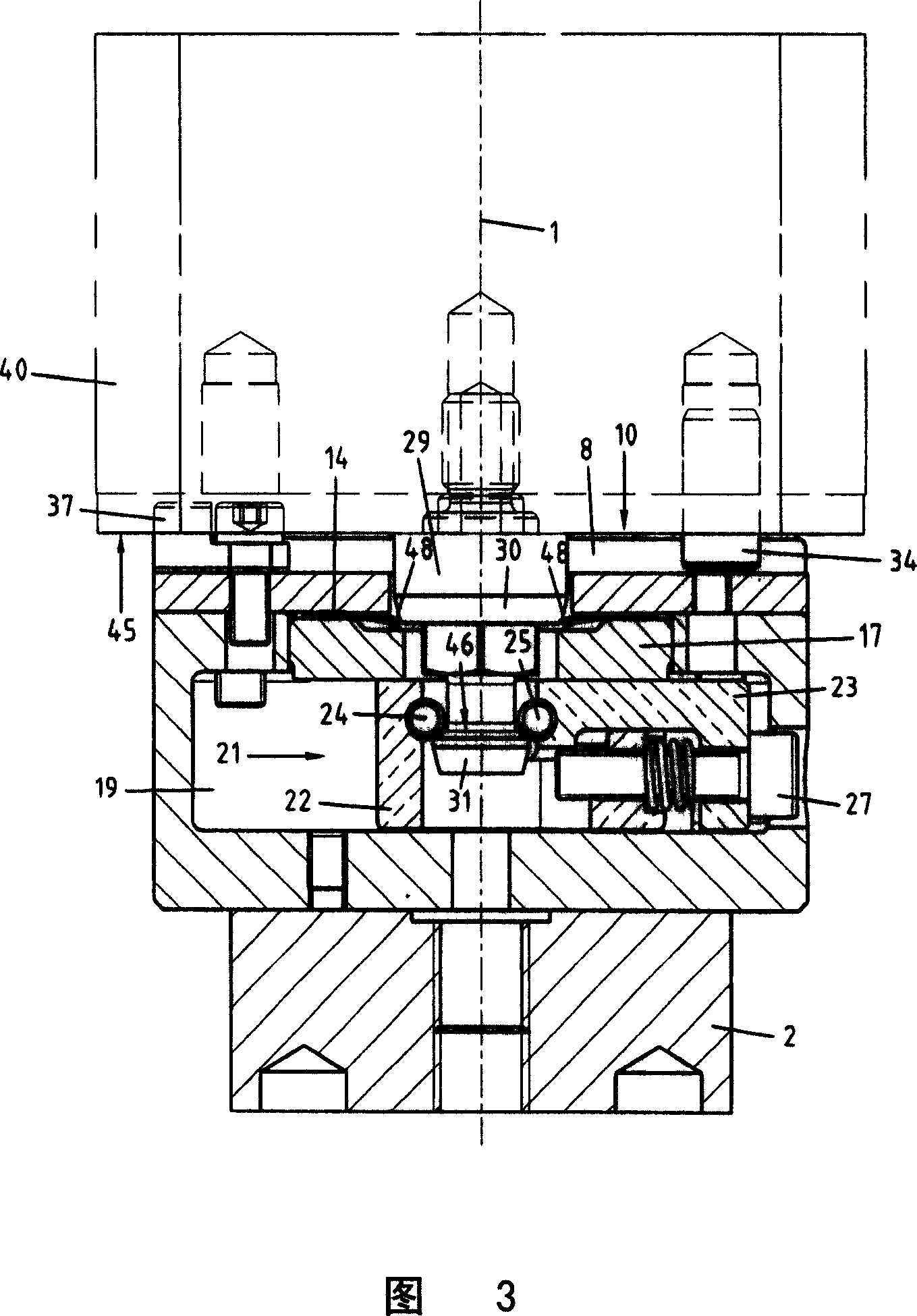

[0014] FIG. 1 shows an exploded perspective view of a clamping device suitable for clamping, for example, a component 40 on a chuck element 3 . The expression "member" should be understood as a general expression for the various parts that may be connected to the chuck element 3; in particular, the member 40 may be a workpiece, a tool or a pallet. Furthermore, it should be noted that members required to connect the chuck parts, such as screws, are not shown in the figures.

[0015] A longitudinal central axis extending through the center of the chuck 3 and of the clamping member 40 and coincident with the Z-axis is indicated generally by reference numeral 1 . It can be seen in FIG. 1 that the plate element 2 to which the chuck can be attached is situated below the chuck 3 . The plate element 2 is an example of a support device provided on a machine tool in which the device is used; in particular, the support device may be a machine tool platform or a casing of the machine too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com