Drive system and drive method of ISG type whole wheel driven hybrid power automobile

A hybrid electric vehicle and drive system technology, applied to the layout of multiple different prime movers, power devices, and electric power devices of general power devices, can solve problems such as high cost, poor performance, and complex structure, and achieve low cost , The transmission scheme is simple and effective, and the effect is easy to realize in engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

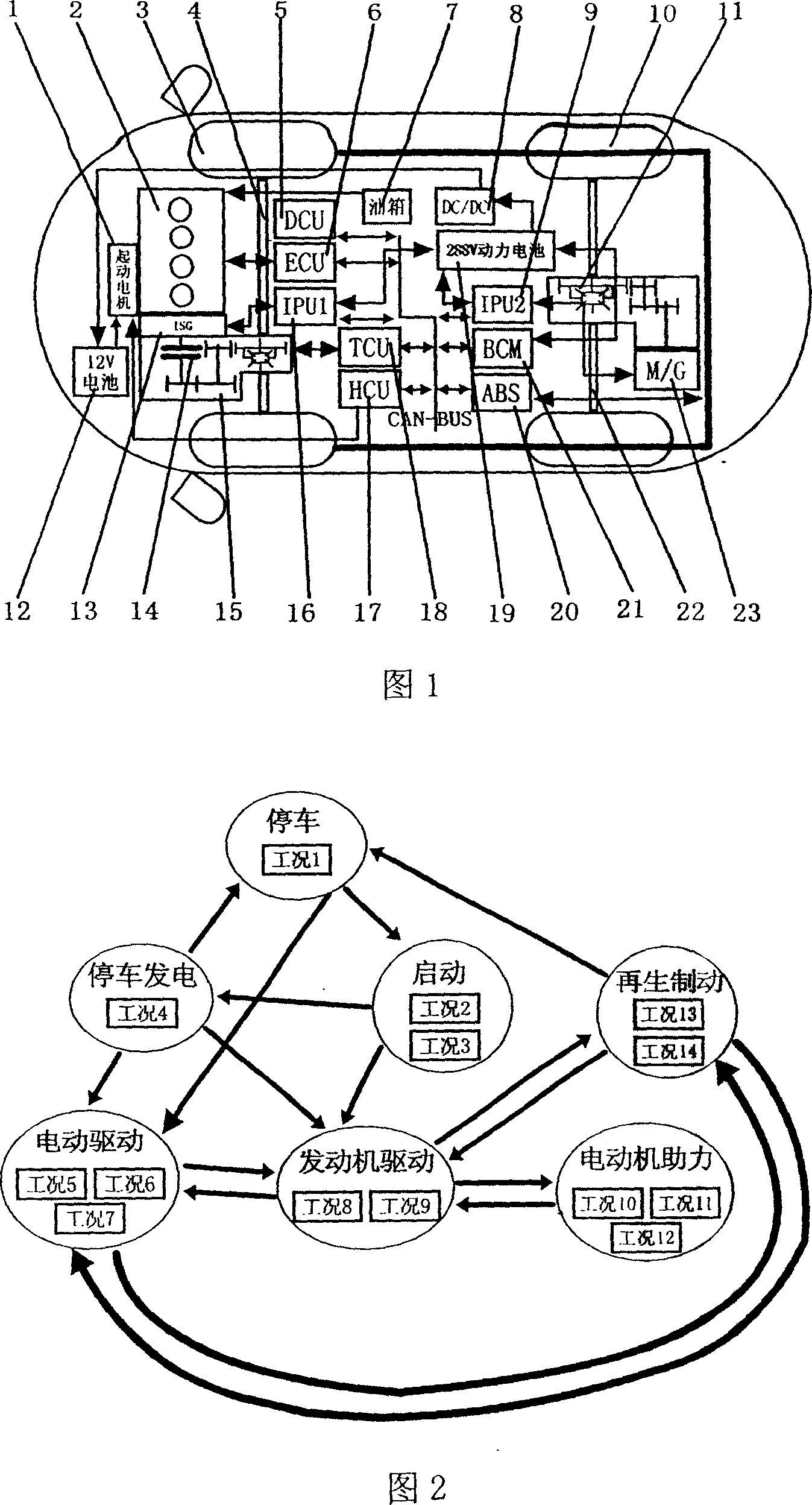

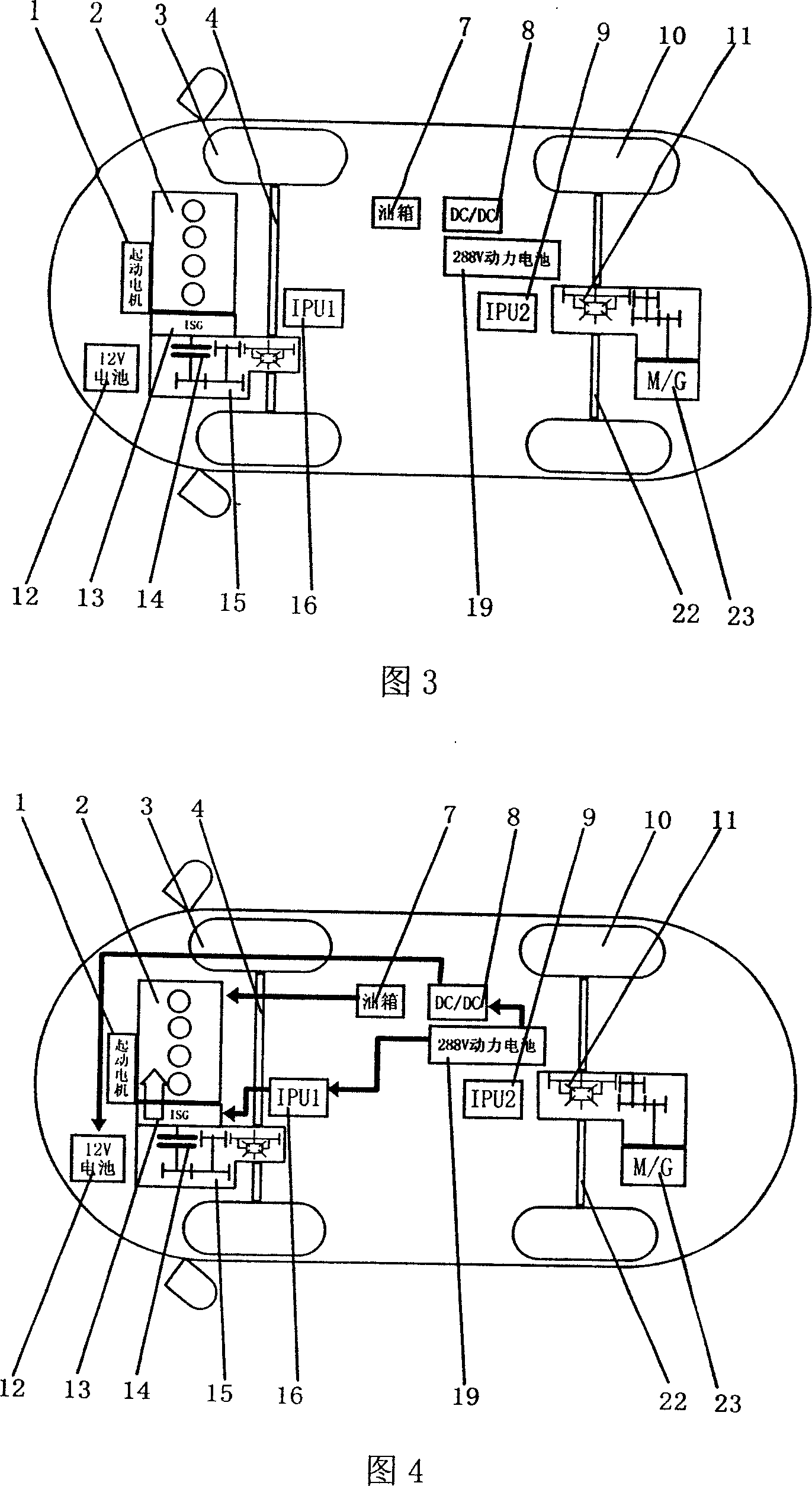

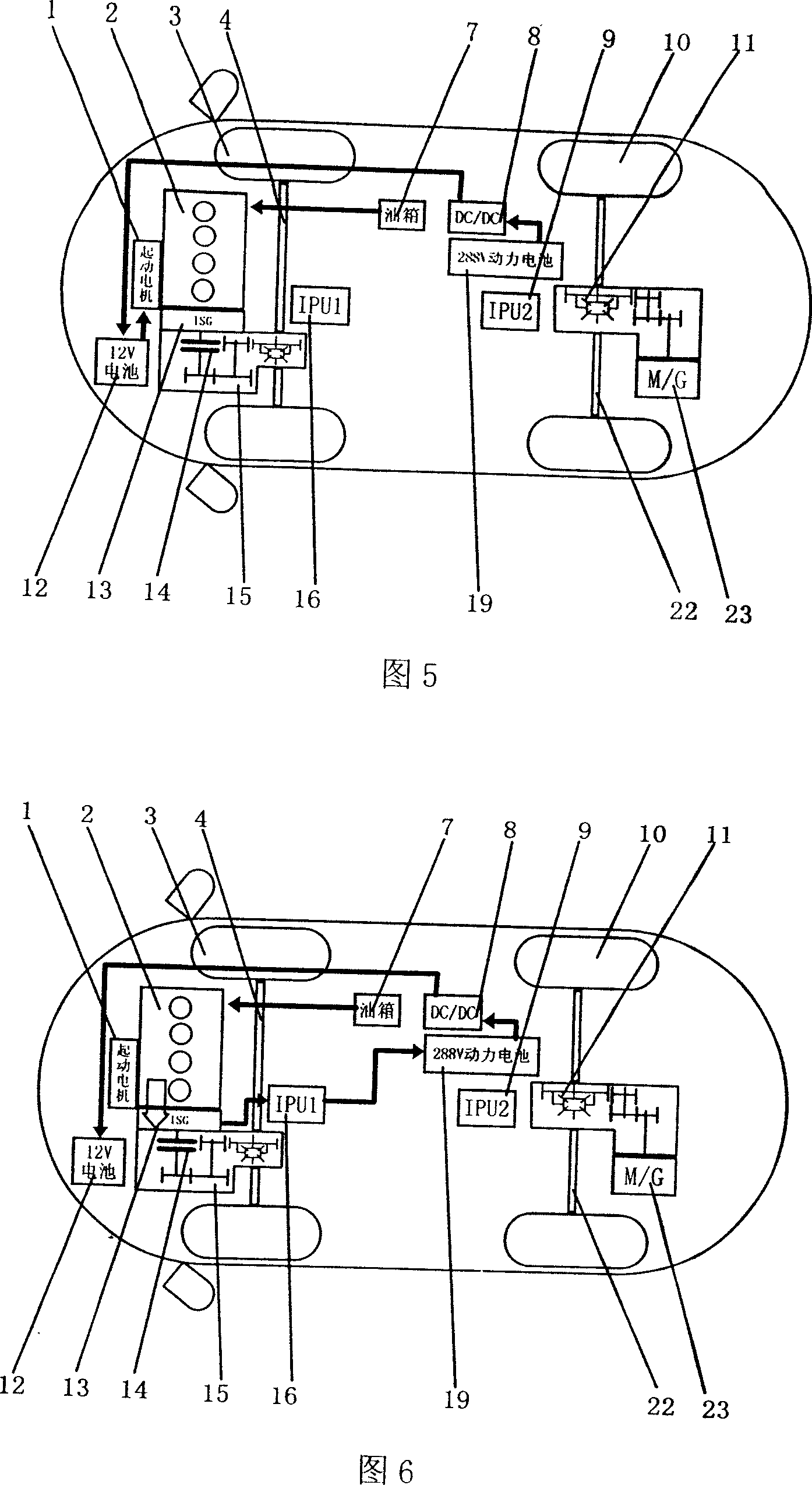

[0026] Figure 1 shows the schematic diagram of the drive system of the all-wheel drive hybrid power system. The drive system is mainly composed of a starter motor 1, a 12V lead-acid battery 12, an engine 2, an ECU engine controller 6, a disc-type ISG motor 13, and an IPU1 front Wheel ISG motor controller 16, automatic clutch 14, transmission 15, TCU automatic clutch / AMT automatic transmission controller 18, front drive shaft 4, front wheel 3, rear wheel drive motor 23, IPU2 rear wheel drive motor controller 9, 288V Ni-MH power battery 19, BCM battery management system 21, rear axle speed reducer / differential 11, rear drive shaft 22, rear wheels 10, HCU hybrid system controller 17, drive system and DCU vehicle information display 5, fuel tank 7. The DC / DC converter 8 and the ABS anti-lock brake controller 20 constitute a matching hybrid power system. .

[0027] Wherein the disc type ISG motor 13 is located between the engine 2 and the automatic clutch 14 / AMT automatic transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com