Reverse osmosis system for realizing on-line backwashing utilizing reverse osmosis system cleaning device

A cleaning device and reverse osmosis technology, applied in the field of reverse osmosis systems, can solve problems such as inconvenient installation, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

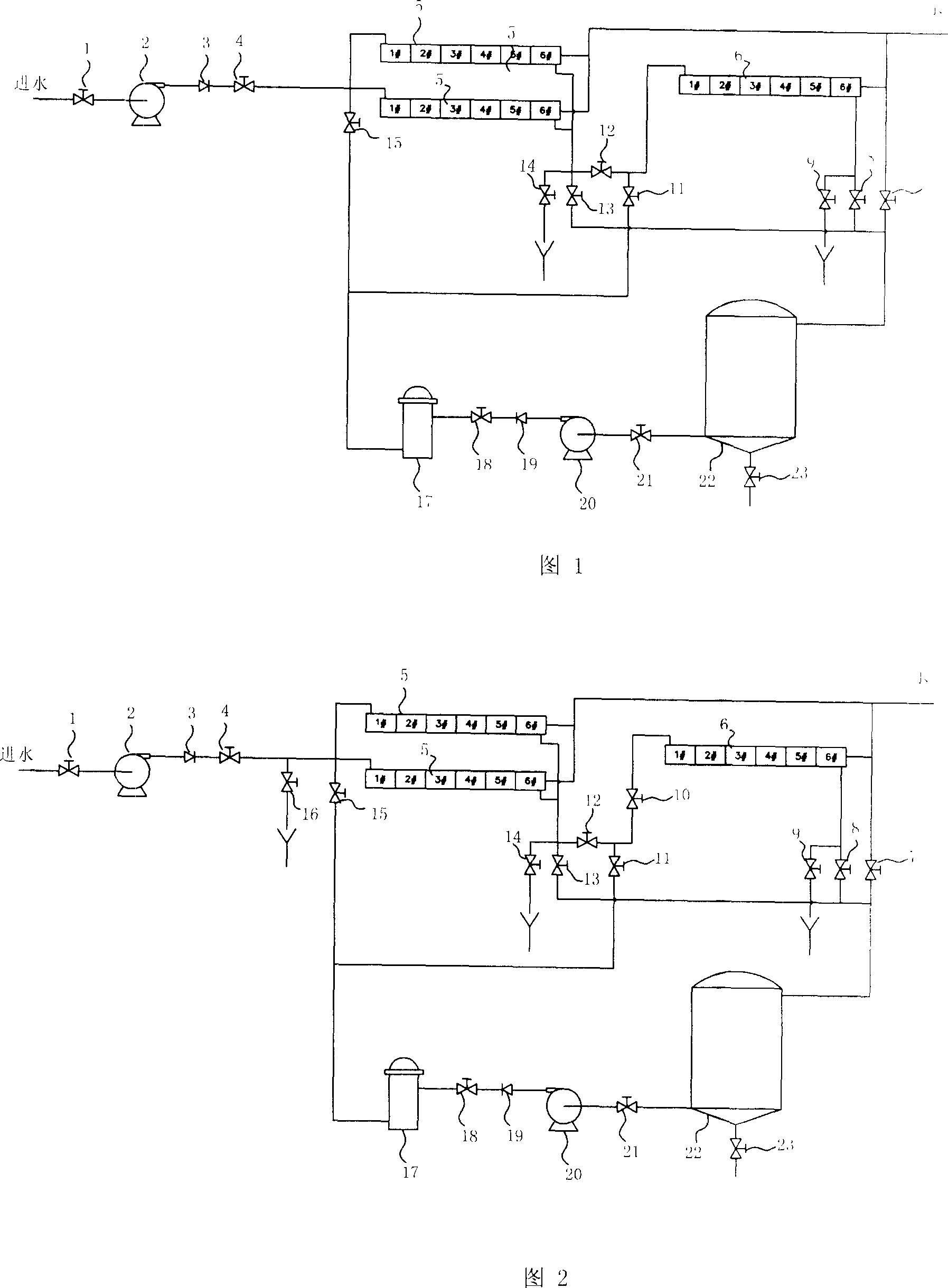

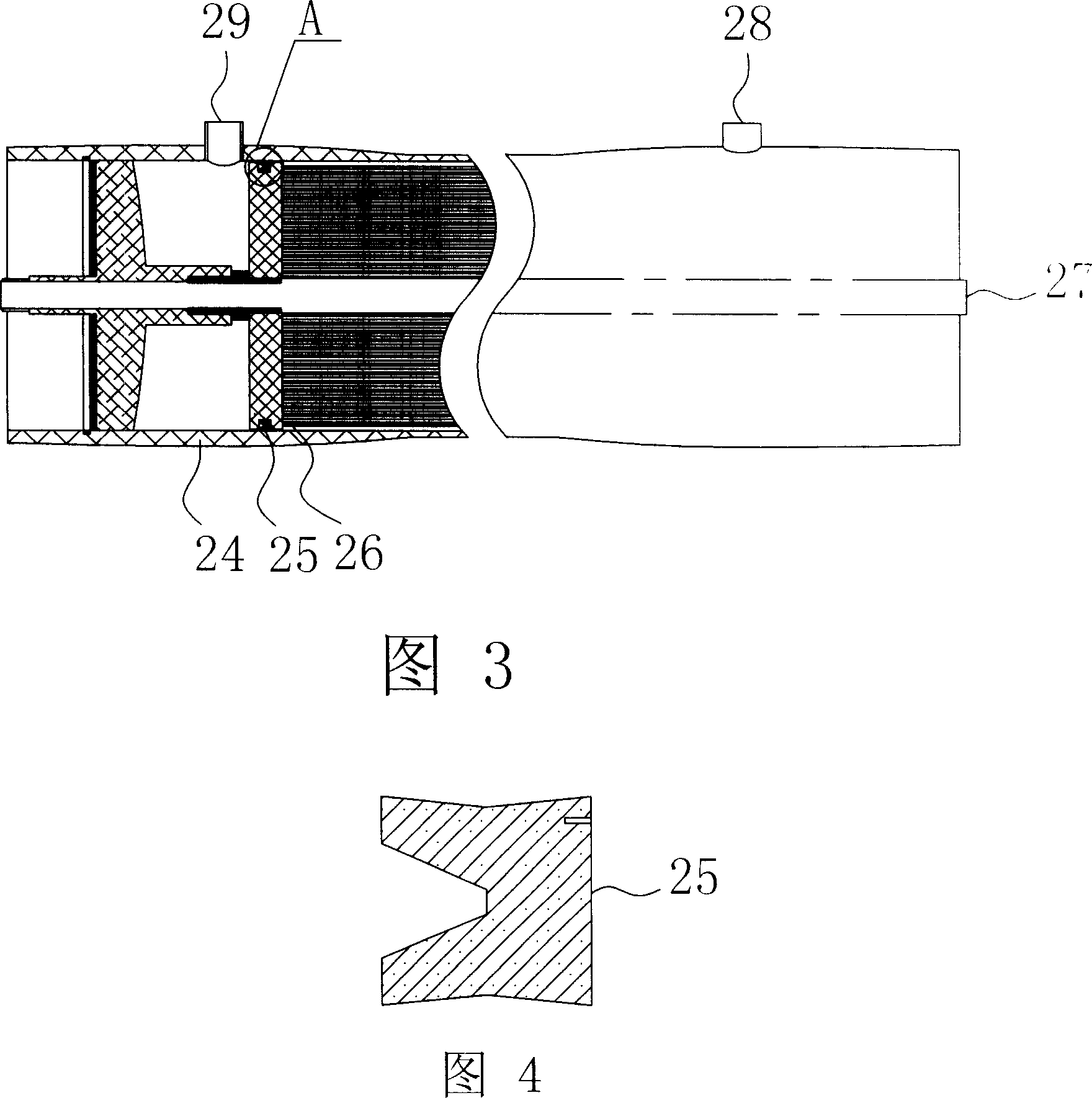

[0015] A preferred embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0016] Referring to Fig. 1, the existing forward cleaning reverse osmosis system includes two or more reverse osmosis membrane modules, here is a second reverse osmosis membrane module, and the first reverse osmosis membrane module 5 is composed of two groups of reverse osmosis membrane modules. Membrane modules are connected in parallel, and the reverse osmosis membrane module 6 in the last stage is composed of a group of reverse osmosis membrane modules; The raw water inlet of the membrane module 5, the concentrated water outlet of the first reverse osmosis membrane module 5 is connected to the raw water inlet of the last reverse osmosis membrane module 6 through the concentrated water inter-stage valve 12; the fresh water outlet of the first and last two reverse osmosis membrane modules Connected to the water production port, the other is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com