Conoid stator longitudinal and bending combination ultrasonic linear motor

A linear motor, composite technology, applied in the directions of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem that the longitudinal vibration frequency of the stator and the bending vibration frequency are difficult to achieve. , The structure is not compact enough, the work efficiency is not high, the positioning and adjustment control is simple, the structure is simple, and the work efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

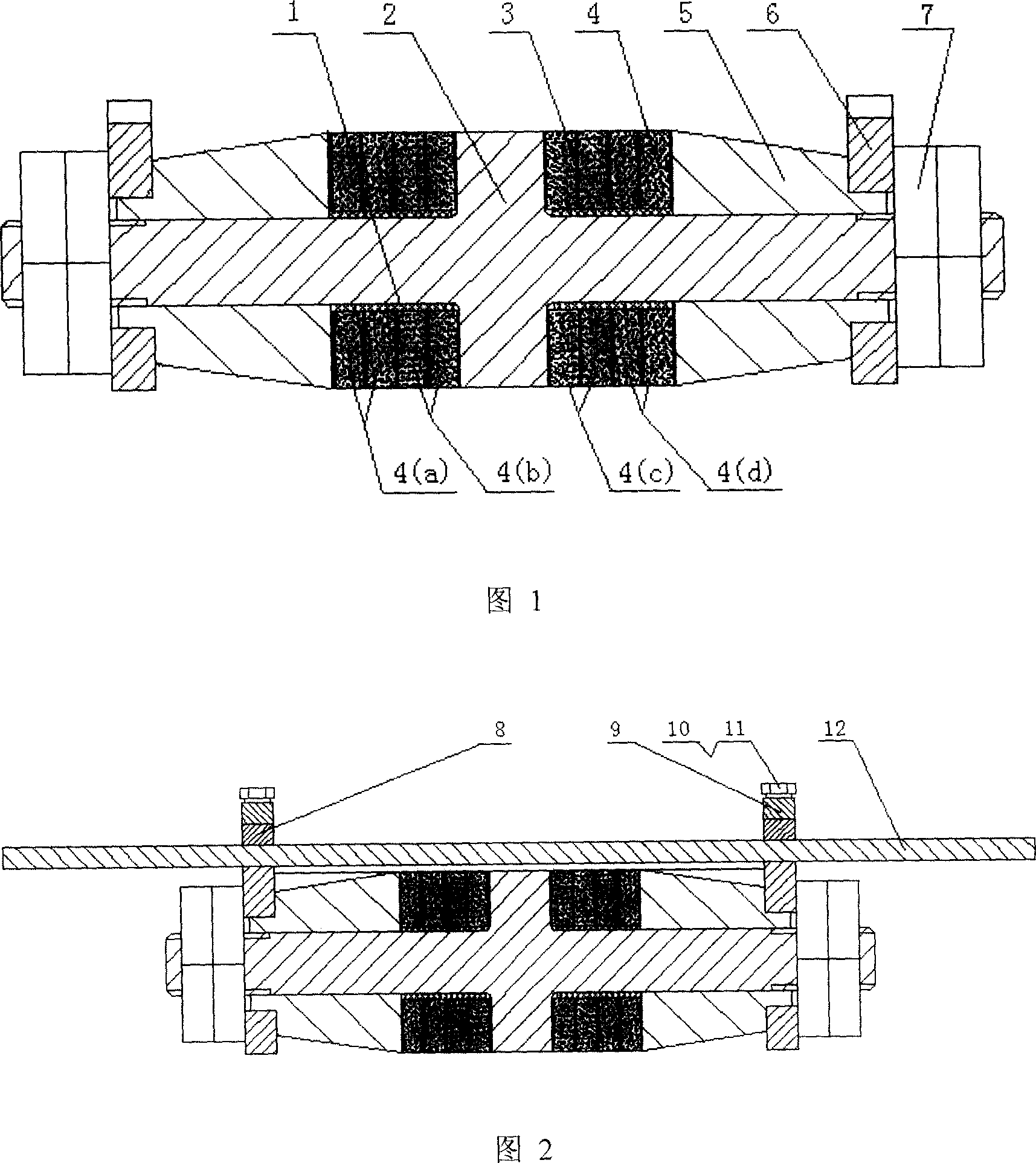

[0015] The invention is a longitudinal-bending composite ultrasonic linear motor developed based on the use of the piezoelectric effect of the piezoelectric ceramic sheet to excite the longitudinal and bending vibration modes of the stator. It is mainly composed of stator and mover. It can be seen from the figure that the longitudinal bending composite ultrasonic linear motor of the present invention adopts a stator with a conical structure, and the stator is composed of eight symmetrically distributed piezoelectric ceramic gaskets 4 acting on the shifting teeth 6 through the double nuts 7 at both ends of the stator and then passing through the pressure shaft sleeve 5 Press the piezoelectric ceramic gasket 4 onto the stud shaft 2. The double nut 7 structure is adopted to ensure the anti-loosening and locking of the ultrasonic linear motor during operation. The shifting tooth 4 adopts a structure in which both sides are convex-shaped and slotted in the middle for the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com