Yellow rice wine heat filling method

A technology of hot filling and rice wine, applied in the field of rice wine production, can solve the problems of long sterilization time, difficult operation, large energy consumption, etc., and achieve the effects of simple operation, energy saving and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

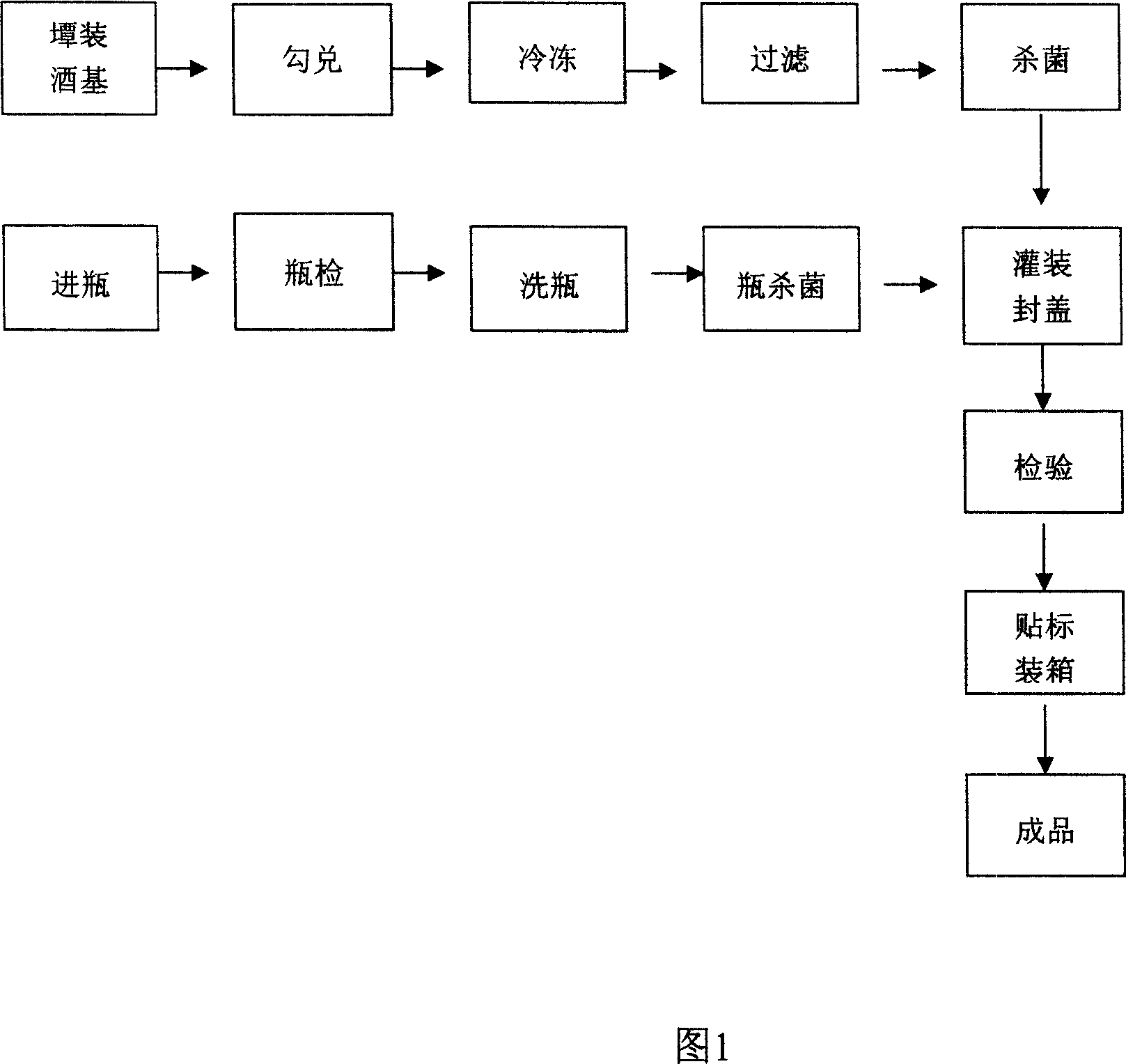

Image

Examples

Embodiment 1

[0014] Freeze the blended rice wine sample 1 from normal temperature to -3°C, and store it in an insulated wine storage tank for 3-5 days; then filter the wine at low temperature with a diatomite filter and fine membrane filter. Filtration; then the wine is heated to 80°C through a thin-plate heat exchanger, and it enters the high-level tank to keep warm for 2 minutes; finally, the sterilized high-temperature wine is put into the sterilized packaging bottle through the filling machine, and the cap is sealed in time.

[0015] Table 1 shows the bactericidal effect of the wine sample 1 after hot-filling. Through the inspection of the number of microorganisms remaining in the wine sample, it was found that the hot-filled wine sample met the hygienic standard.

[0016] Table 1 The number of bacterial colonies in wine sample 1 before and after hot filling

[0017] Before hot filling

after hot filling

Bacterial colony count (unit / ml)

2.3×10 6

...

Embodiment 2

[0022] After the blended rice wine sample 2 was frozen from normal temperature to -2°C, it was stored in an insulated wine storage tank for 4 days; then the wine was filtered with a diatomaceous earth filter and a membrane fine filter at a low temperature; Then the wine is heated to 82°C through a thin-plate heat exchanger, and it enters the high-level tank to keep warm for 3 minutes; finally, the sterilized high-temperature wine is put into the sterilized packaging bottle through the filling machine, and the cap is sealed in time.

[0023] Table 3 shows the number of microbes remaining in the wine sample after the hot filling of the wine sample 2, and it was found that the hot filled wine sample 2 met the hygienic standard.

[0024] Table 3 The number of bacterial colonies in wine sample 2 before and after hot filling

[0025] Before hot filling

after hot filling

Bacterial colony count (unit / ml)

2.4×10 6

4

[0026] The...

Embodiment 3

[0030] After the blended rice wine sample 3 was frozen from normal temperature to 0°C, it was stored in an insulated wine storage tank for 4 days; then the wine was filtered with a diatomaceous earth filter and a membrane fine filter at a low temperature; then The wine is heated to 83°C by a thin-plate heat exchanger, and it is kept in a high-level tank for 2.5 minutes; finally, the sterilized high-temperature wine is put into a sterilized packaging bottle through a filling machine, and the cap is sealed in time.

[0031] Table 5 shows that after the wine sample was hot-filled, the number of microorganisms remaining in wine sample 3 was inspected, and it was found that the wine sample 3 after hot filling met the hygienic standard.

[0032] Table 5 Number of bacterial colonies in wine sample 3 before and after hot filling

[0033] Before hot filling

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com