Cement interface shearing in annulus supersonic ultrasonic testing method

A testing method and technology of cement sheath, applied in the directions of surveying, earthwork drilling, wellbore/well components, etc., can solve the problem of not revealing the relationship of various parameters downhole, not revealing the hydraulic bonding strength and shear bonding strength of the cement sheath. Problems with compressive strength of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

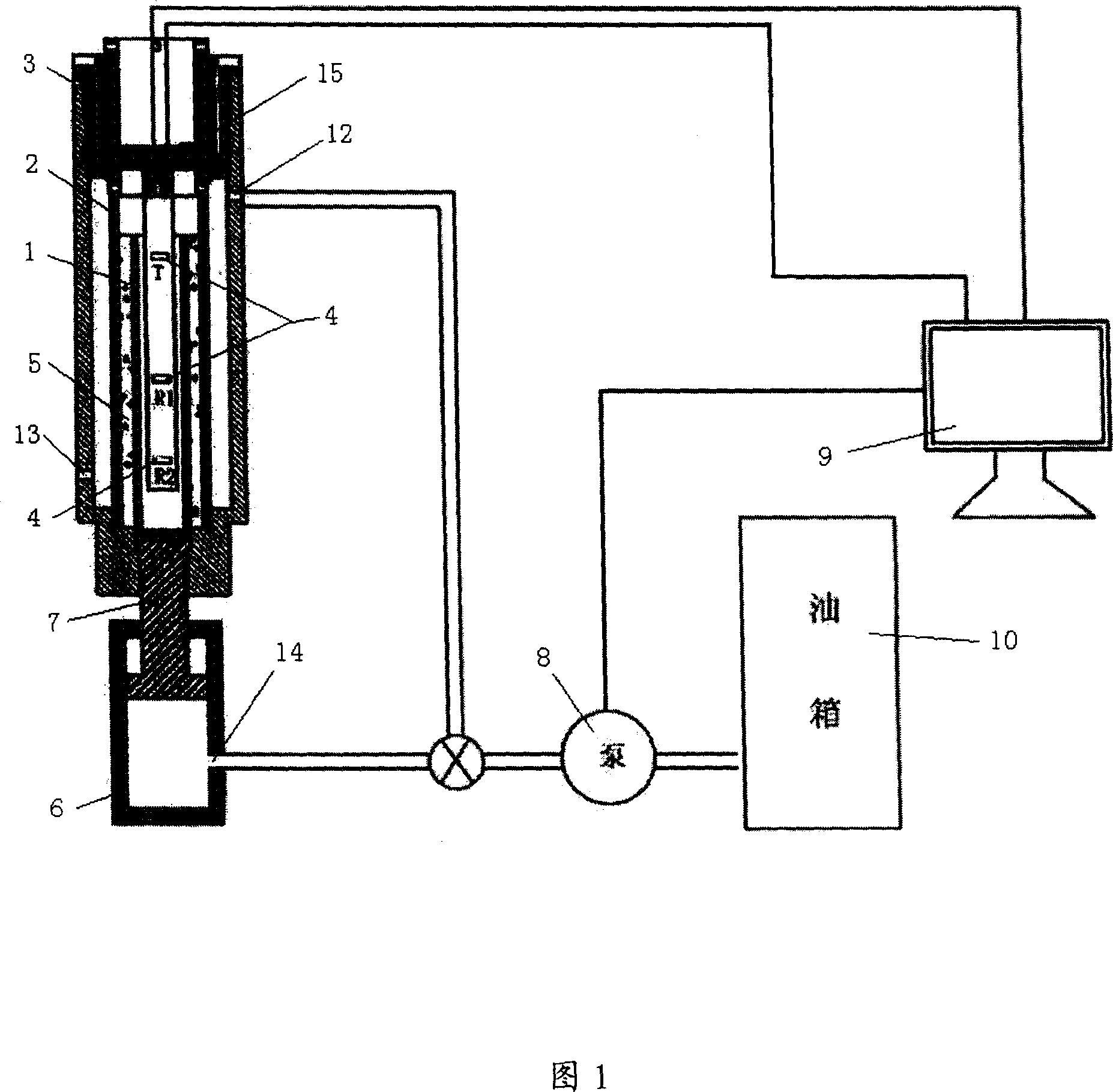

[0043] As shown in FIG. 1 , a preferred embodiment of the cement sheath interface shear ultrasonic tester includes an oil tank 10 and an oil pump 8 , and the oil tank 10 and the oil pump 8 are connected through pipelines. An upper cover 3 is arranged on the upper part of the pressure vessel 11 , and the upper cover 3 is provided with an upper cover through hole 15 . The pressure vessel 11 is provided with an outer casing 2 inside, and an inner casing 1 is arranged inside the outer casing 2 , and the height of the inner casing 1 is lower than that of the outer casing 2 . The lower part of the pressure vessel 11 is provided with a piston 7, the upper part of the piston 7 is in contact with the lower part of the inner casing 1, and the lower part of the piston 7 is provided with a thrust cylinder 6, and the piston obtains upward thrust through the thrust cylinder 6. Thrust oil cylinder 6 is provided with thrust oil cylinder hole 14 on the side, and this thrust oil cylinder hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com