Heat resistance network model and method for calculating junction temperature of microelectronics using same

A technology for microelectronic devices and network models, which is applied in computing, instrumentation, electrical digital data processing, etc., and can solve problems such as poor thermal resistance prediction accuracy of simple thermal model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

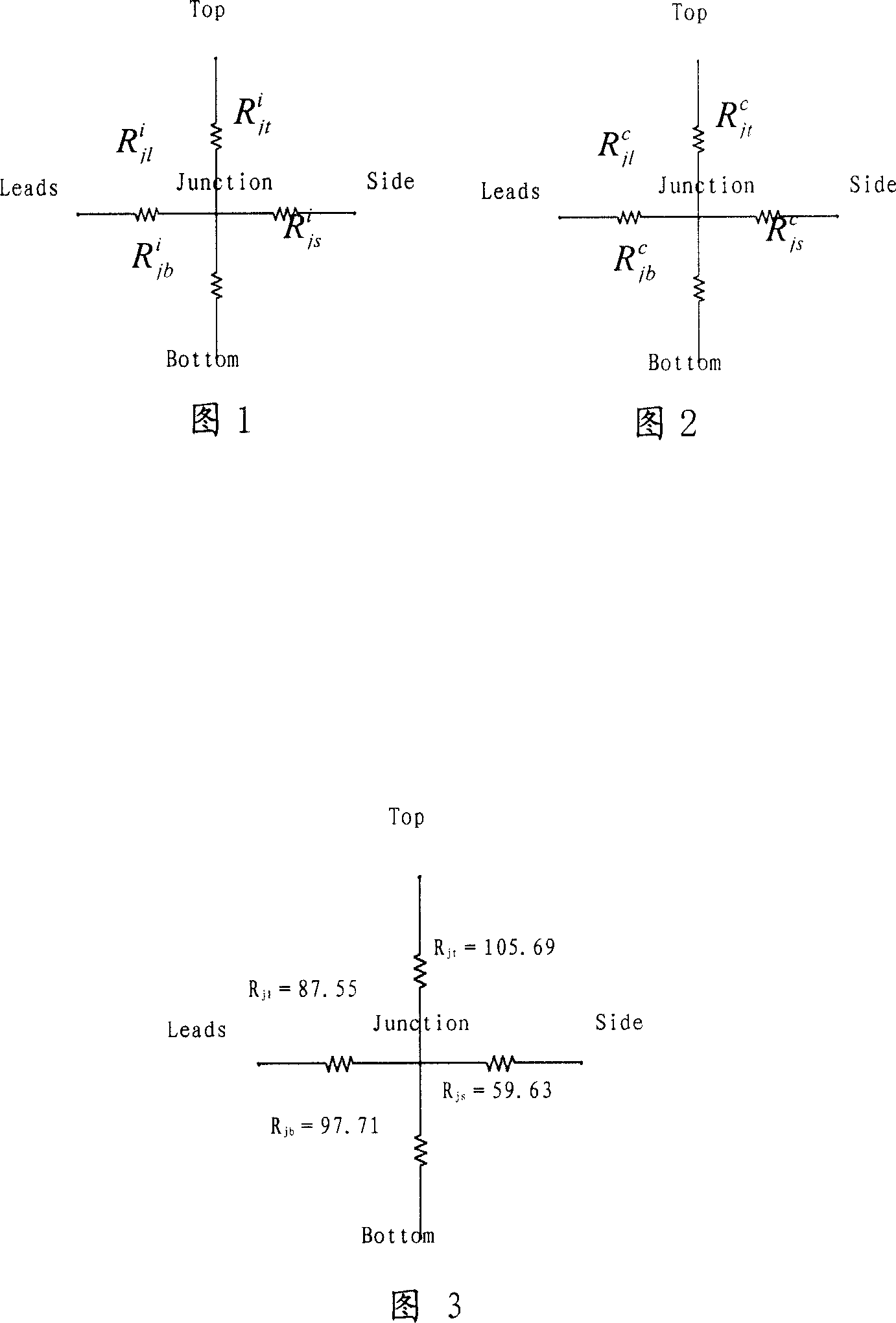

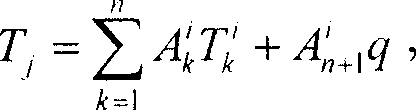

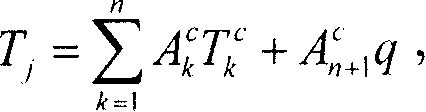

[0027] Please refer to Fig. 1 and Fig. 2, the thermal resistance network of the present invention adopts star structure representation, constitutes with the four nodes that represent top surface, side, bottom surface and pin that are connected with junction, pass branch road between each node and junction The thermal resistances are connected, and the thermal resistances of each branch respectively represent the effect of the top surface, side surface, bottom surface and pins on the heat dissipation of the device. The intrinsic thermal resistance network and the nominal thermal resistance network use the same structure, the intrinsic thermal resistance network is used for isothermal boundary conditions, and the nominal thermal resistance network is used for convective boundary conditions.

[0028] The following is the modeling and junction temperature calculation process of microelectronic devices:

[0029] (1) Improve the existing definition of thermal resistance, and propose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com