Making method of connector jack

A technology of a connector socket and a manufacturing method, which is applied to the connection, the parts of the connection device, the contact parts, etc., can solve the problems such as the inability to eliminate terminal processing errors and slight deformation, high after-sales service costs, and unstable product quality. Reduce the cost of after-sales service, solve the problem of unstable quality, and achieve good product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

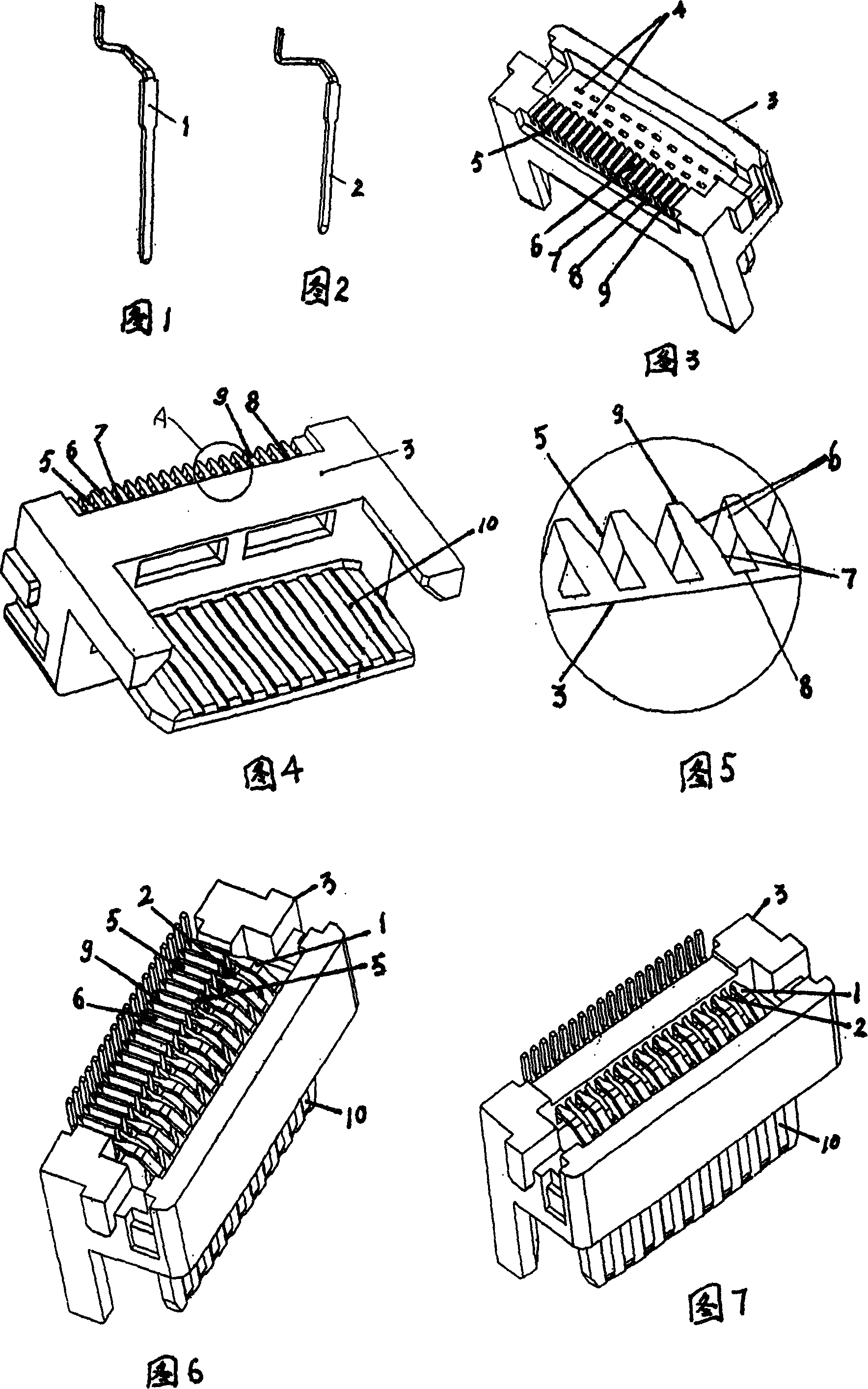

[0014] Referring to Figures 1-7, a method for manufacturing a connector socket, the connector socket is composed of a shell, a base 3 and terminals, part of the terminal has a gold-plated contact surface, and a part is a welding foot, the base 3 is fixed in the shell, and the base Mounting groove 10 is formed in 3, and base 3 rear portion is shaped on a row of grooves 5, and both sides of front portion in this groove 5 are inclined planes 6, both sides of rear portion are side planes 7, the bottom is bottom plane 8, and a row of grooves Corresponding to the slot 5, two rows of mounting holes 4 are made at the rear of the base 3, the terminals are made into a "ㄅ" shape, the terminals are made into terminal one 1 and terminal two 2, the lower part of the terminal has a gold-plated contact surface, and the upper part of the terminal is a soldering foot , the lower part of the terminal is inserted into the mounting hole 4 of the base 3 and protrudes from the mounting hole 4 to be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com