Friction roller type controllable sliding oil-saving clutch

A sliding device and clutch technology, which is applied in the direction of friction clutches, clutches, one-way clutches, etc., and can solve problems such as vehicle forward and backward, joints are not smooth, and gears cannot be shifted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

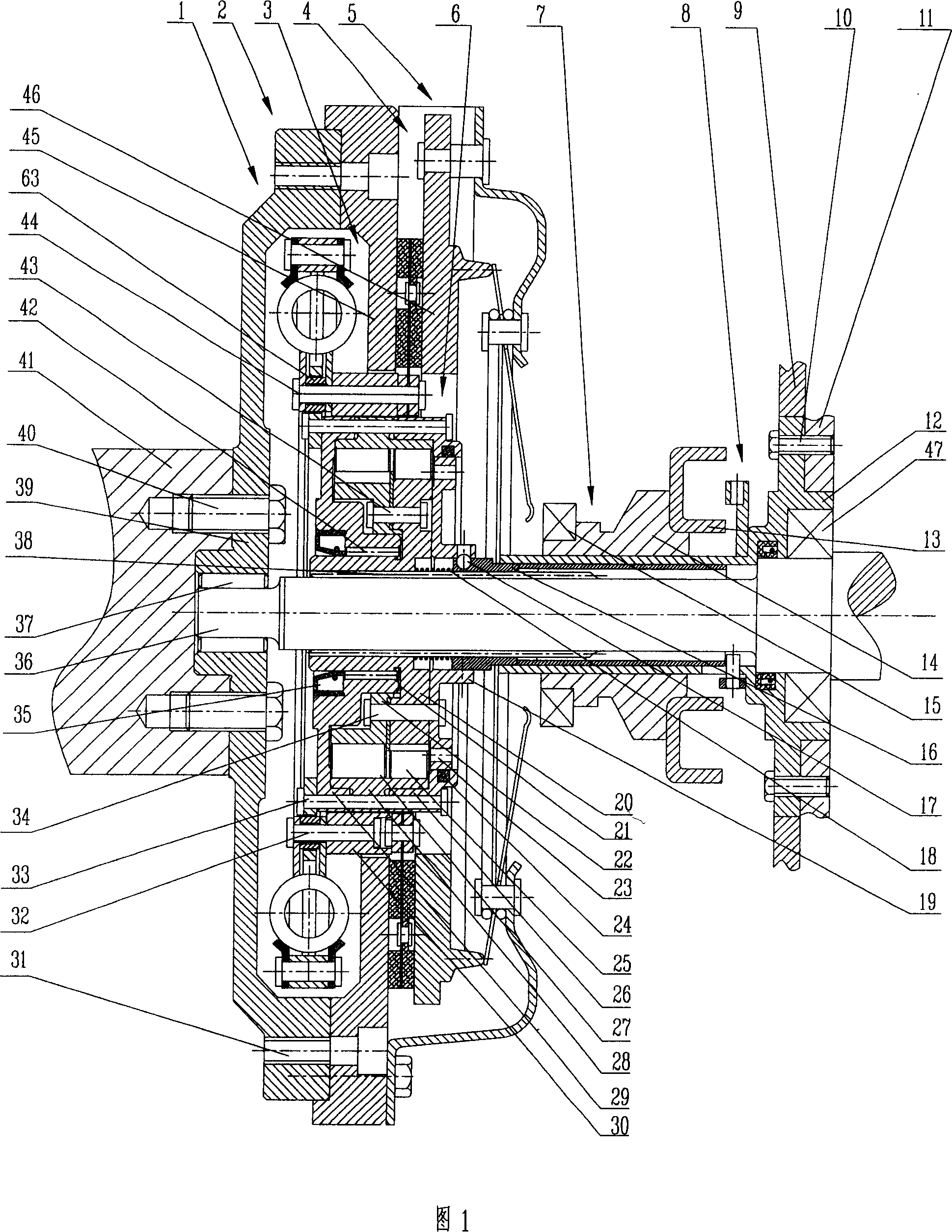

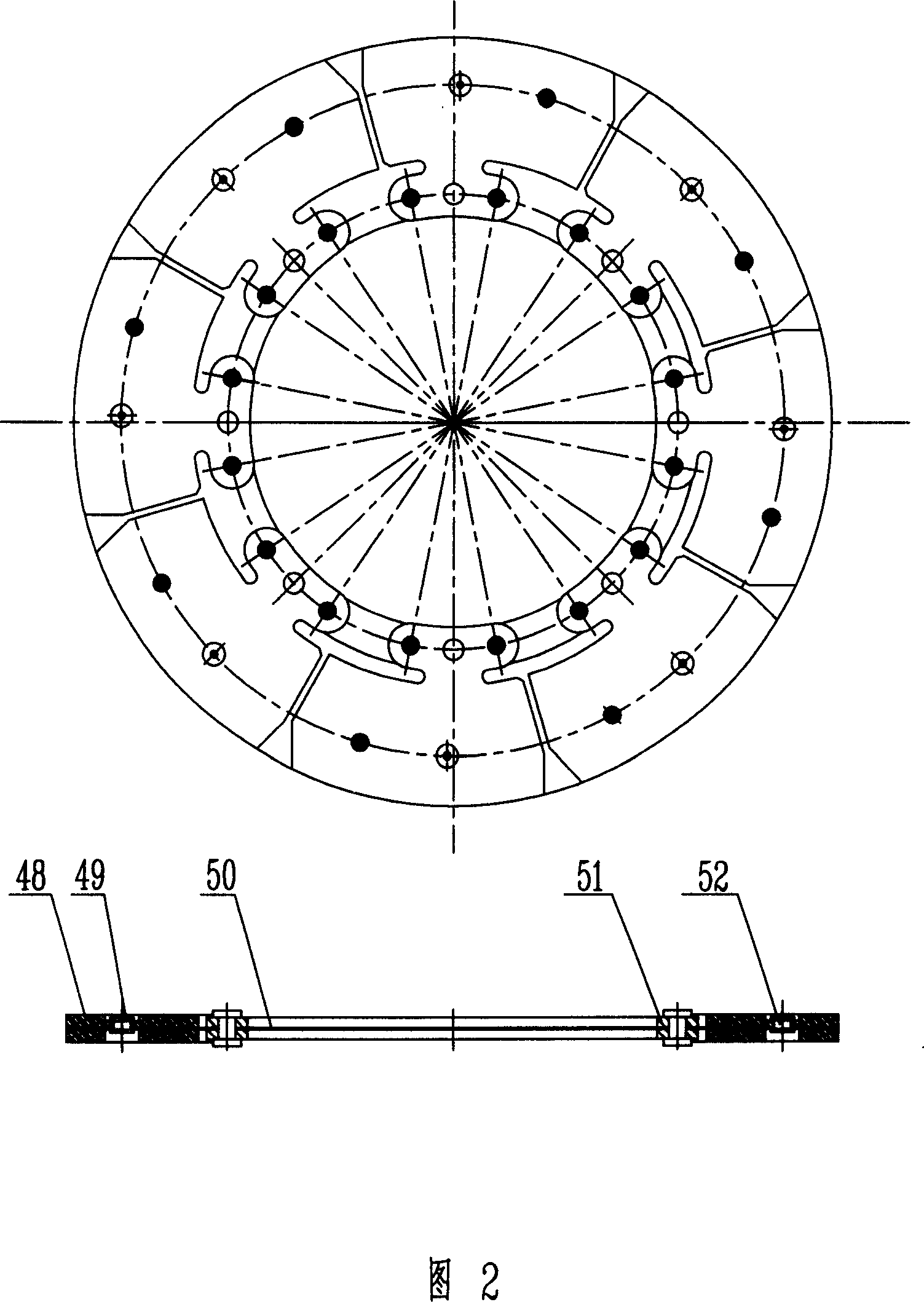

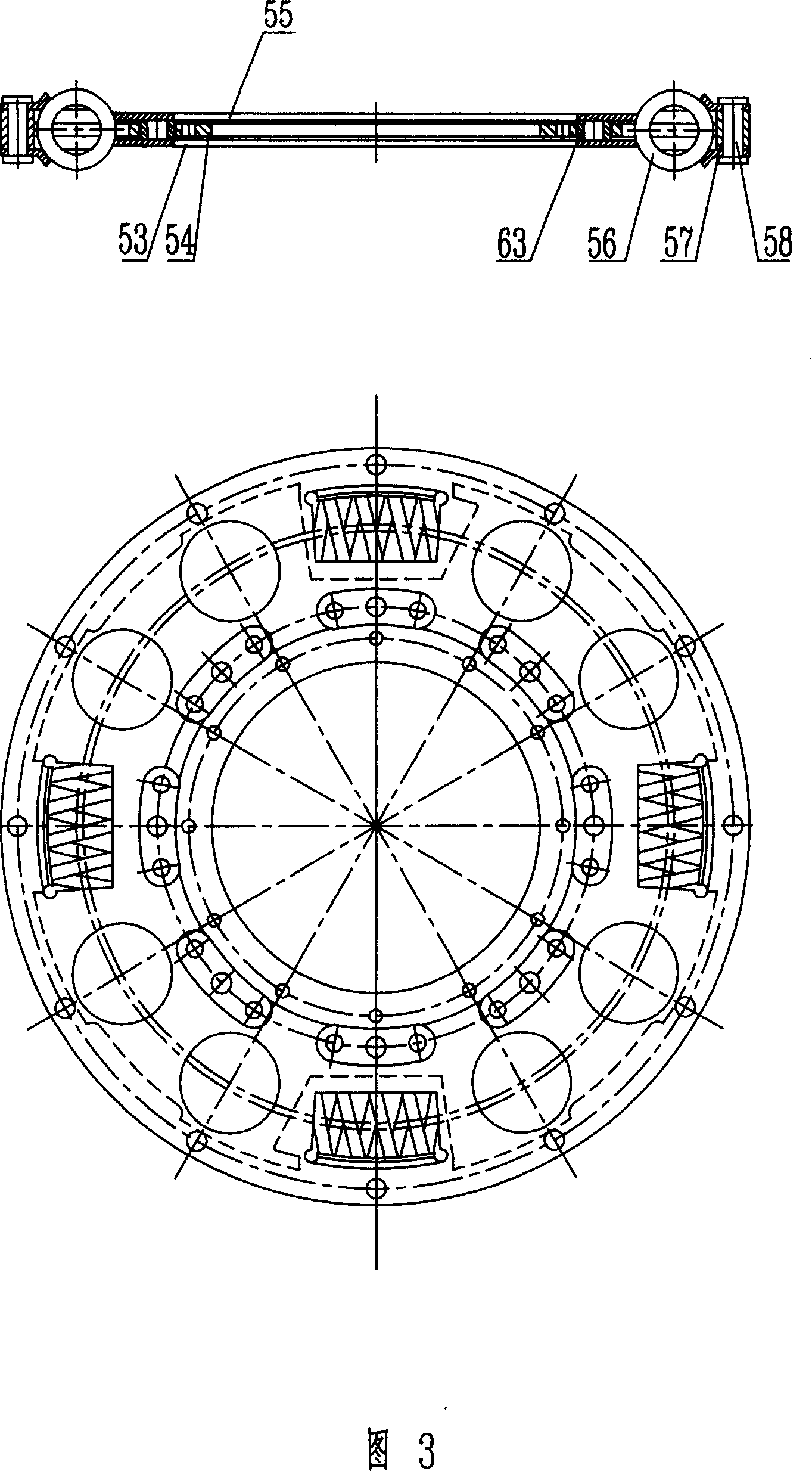

[0014] Embodiments of the present invention are described below according to the accompanying drawings. In this description, "front" refers to the side close to the engine, and "rear" refers to the side away from the engine and close to the transmission. What Fig. 1 shows is the longitudinal sectional view of the friction roller type controllable slip fuel-saving clutch 1 of Embodiment 1 of the present invention, Fig. 2 is the longitudinal sectional view of the clutch driven disc assembly 4 of Embodiment 1, and Fig. 3 is the longitudinal sectional view of Embodiment 1 The side view and sectional view of the torsional shock absorber, Fig. 4 is the driving of the two-way overrunning clutch assembly 6 of embodiment 1 and the longitudinal view of the sliding overrunning clutch when driving, Fig. 5 is the two-way overrunning clutch assembly of embodiment 1 6 is a longitudinal sectional view of the drive and coasting overrunning clutch when coasting, and Fig. 6 is a longitudinal cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com