Flow guiding bevel-type pure smokless combustion device

A smokeless combustion and diversion cone technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of extremely serious energy waste, environmental pollution, etc., achieve significant economic and social benefits, save coal resources, and structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

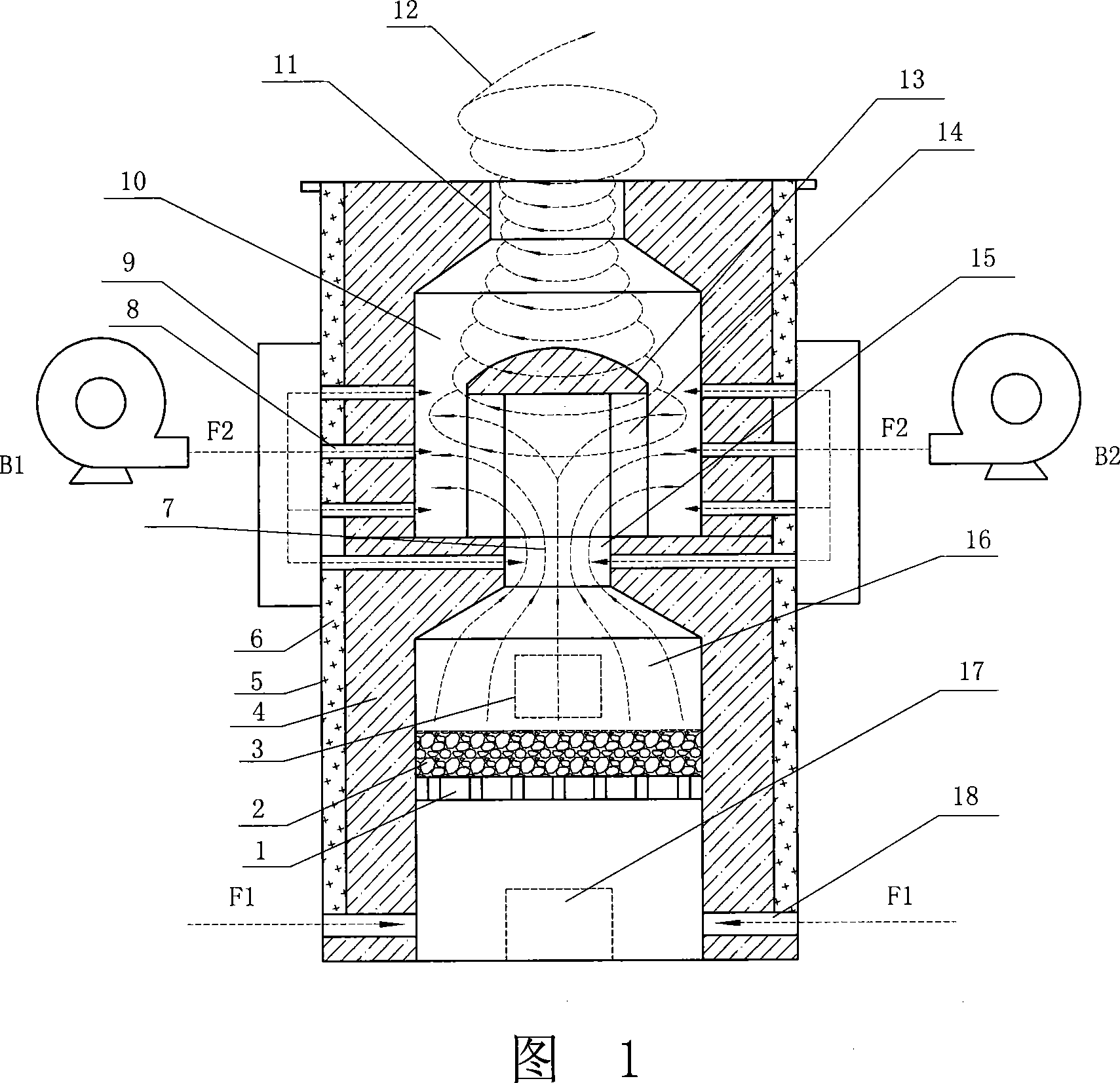

[0029] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

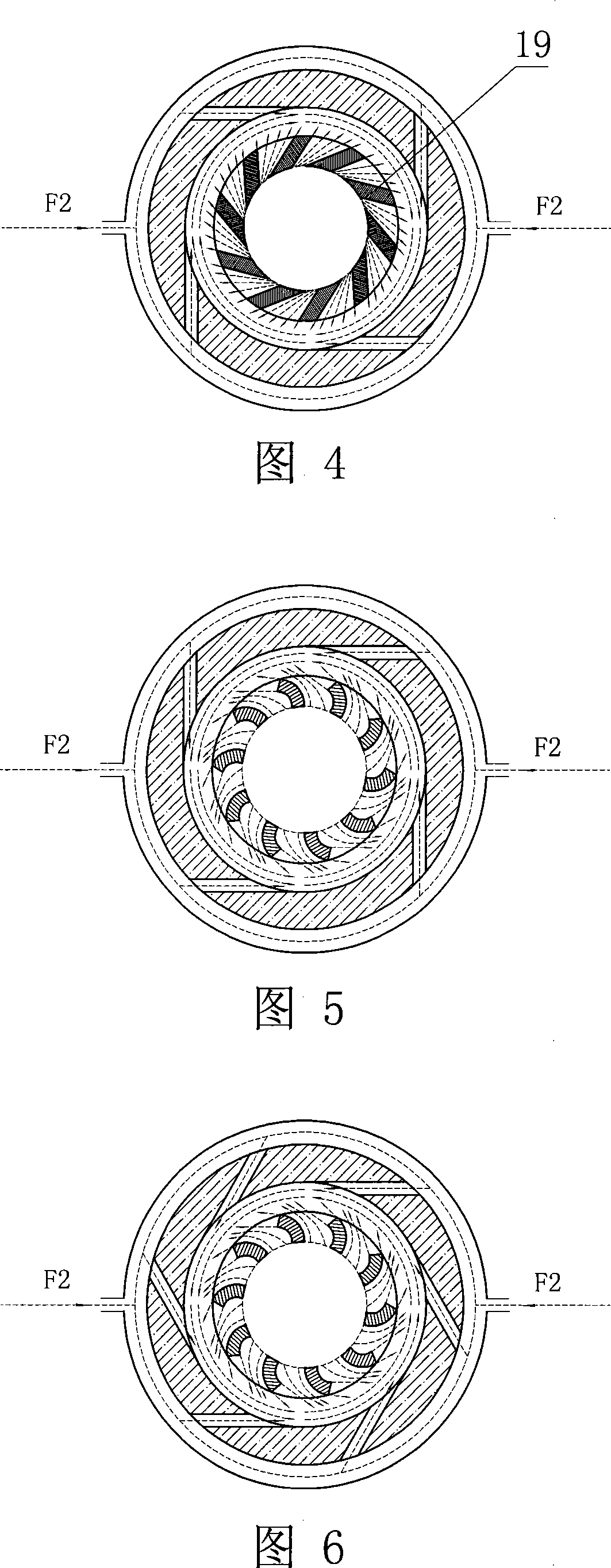

[0030] What Fig. 1 shows is the embodiment 1 of diversion cone type pure smokeless combustion device of the present invention, the top of fire grate 1 is combustion furnace 16, the bottom of fire grate 1 is ash chamber, and combustion furnace 16 is correspondingly arranged There is a coal stoker door 3, and an ash discharge door 17 is provided corresponding to the ash chamber. The top of the gas outlet 15 is provided with a secondary combustion furnace 10, the cross section of the secondary combustion furnace 10 is circular, and a diversion cone is arranged in the secondary combustion furnace 10 corresponding to the high-temperature flue gas outlet 15, and the diversion cone consists of longitudinal, circumferential The distributed high-temperature flue gas deflector 14 and the top cover 13 on the top of the deflector are composed, the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com