Automatic decting method and device for wheel hub casting fault based on image understanding

A technology for automatic detection of casting defects, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems that do not involve wheel interactive communication and mechanism action control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

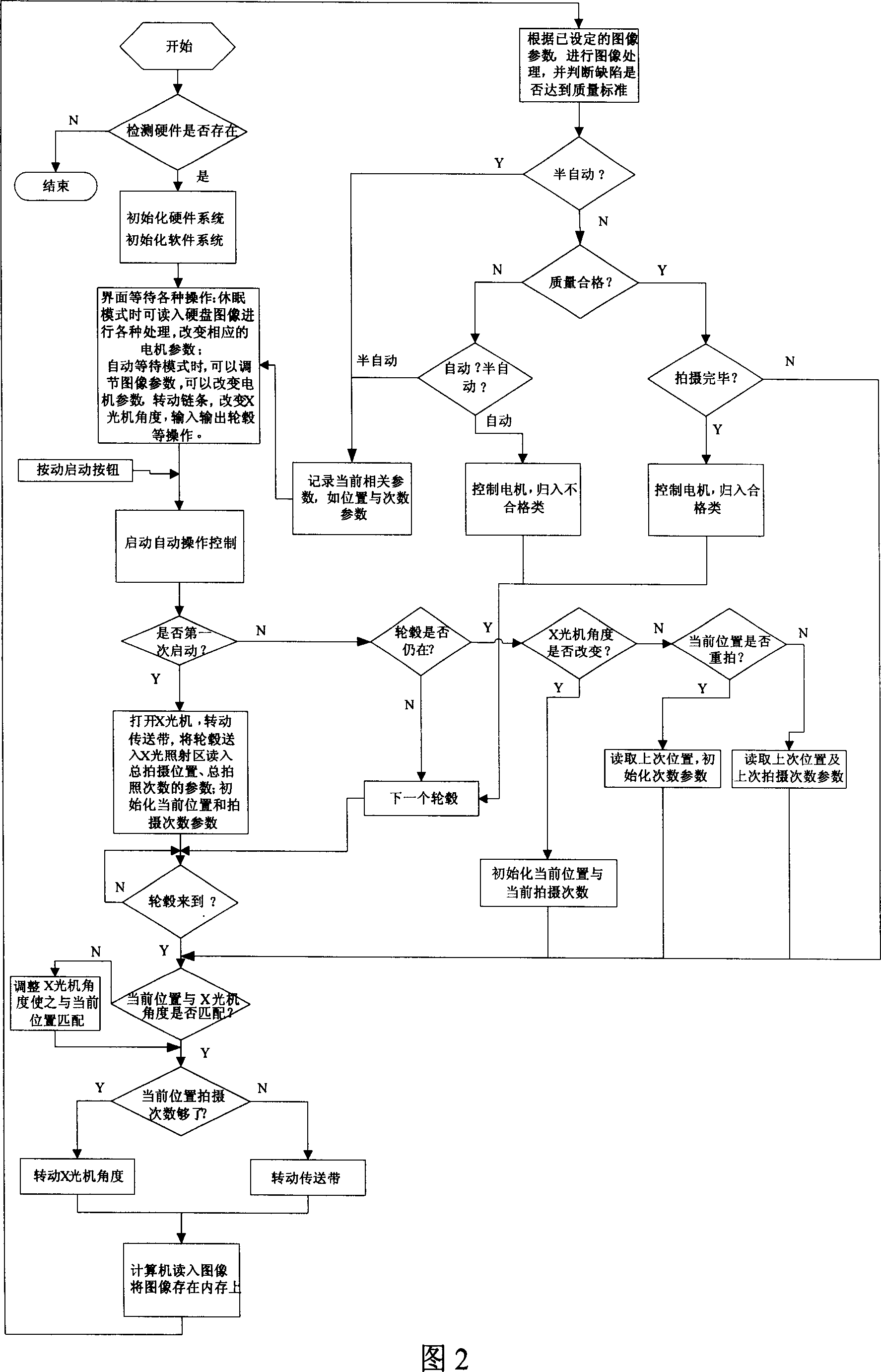

[0085] The automatic detection method and device for wheel hub casting defects based on image understanding of the present invention are realized by combining software and hardware, and can detect both surface defects and internal defects. The software part is written in Fortran or C language on a general-purpose computer.

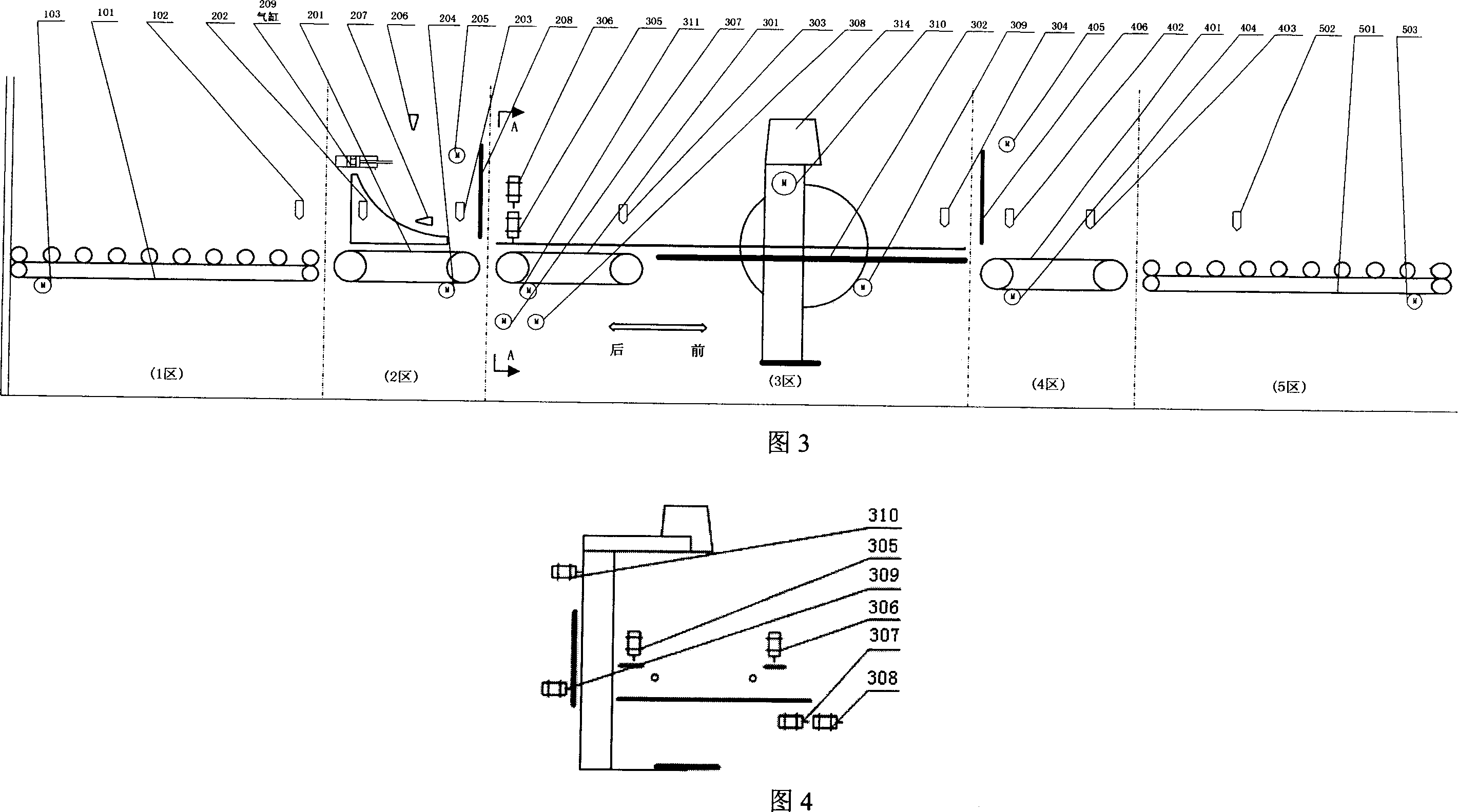

[0086] The method and system of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted here that the shapes and sizes in the drawings are only used for clearer explanation, rather than for expressing strict proportional relationship.

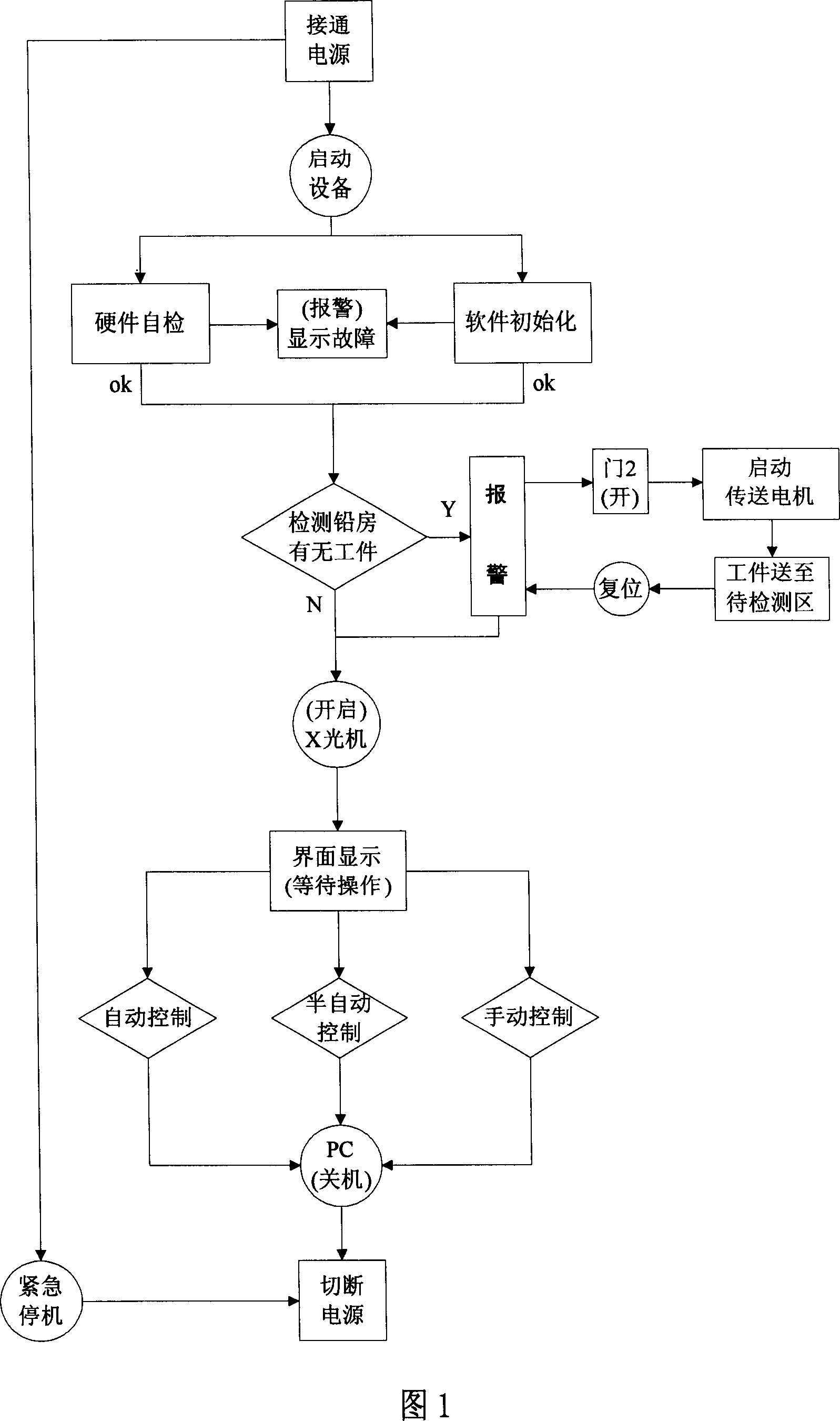

[0087] Fig. 1 is the overall work flowchart of the device of the present invention. There is an emergency stop button in the device. If you need an emergency stop after the power is turned on, you can press the emergency stop button to cut off the power supply. The normal working process is as follows:

[0088] (1) Turn on the power and start the device.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com