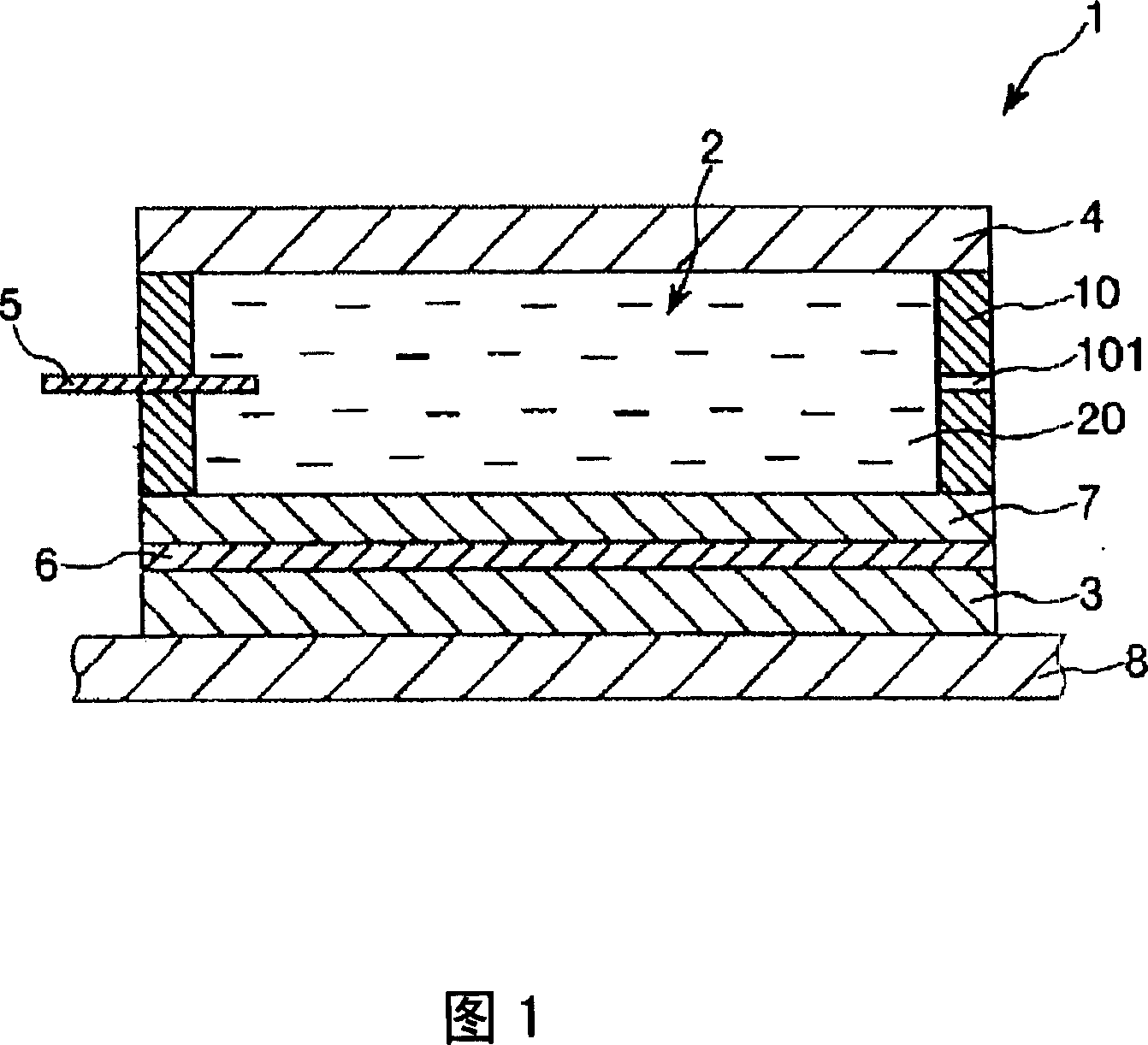

Method for forming film, base plate with film, sensor, and liquid composition

A composition and liquid technology, applied in chemical method analysis, instruments, scientific instruments, etc., can solve the problems of protein physiological activity reduction and inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

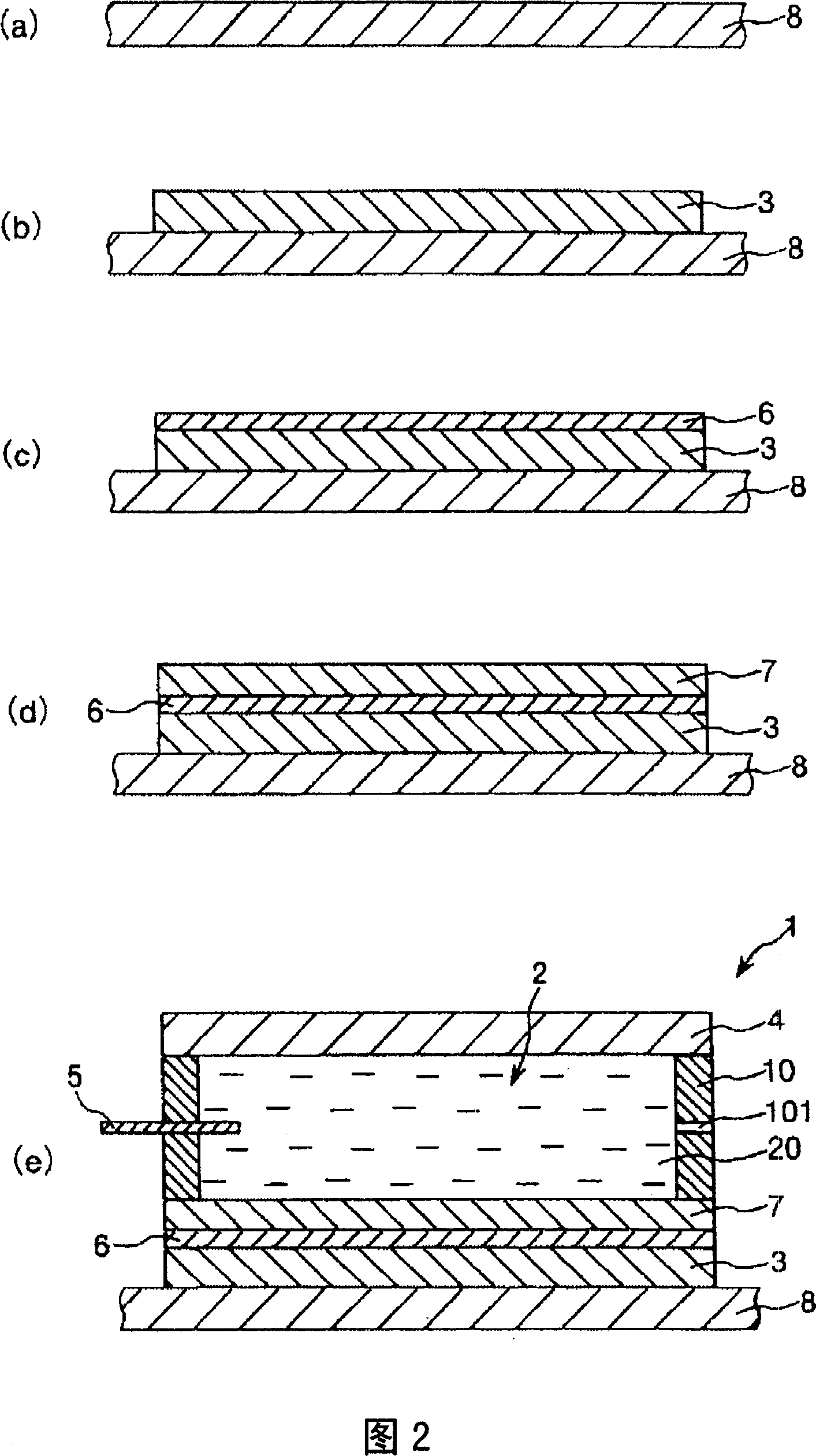

Embodiment 1

[0203] First, a glass substrate was prepared, and an Ag electrode (working electrode) having an average thickness of 200 nm was formed by vacuum deposition.

[0204] Next, albumin, which is a bio-related polymer, was dissolved in pure water to prepare an albumin-containing solution.

[0205] Next, the albumin-containing solution was supplied onto the working electrode by an inkjet method to form a liquid coating, and then dried under the conditions of 60° C.×30 minutes in an atmospheric pressure atmosphere to obtain a base layer.

[0206] Next, the liquid composition of sample No. 1 is supplied to the ink chamber of the inkjet printer (manufactured by Seiko Epson Corporation, "PM700"), and then the piezoelectric element provided in the ink chamber is operated to generate The form of droplets is provided onto the substrate layer. In this way, a liquid film is formed on the base layer. In addition, the viscosity and surface tension of the liquid composition were 3.6 cP and ...

Embodiment 2

[0212] In said process , the sensor was produced similarly to Example 1 except having used sample No. 2 instead of sample No. 1 as a liquid composition.

Embodiment 3

[0214] In said process , the sensor was produced similarly to Example 1 except having used sample No. 3 instead of sample No. 1 as a liquid composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com