Method for manufacturing titanium ball and titanium ball

A manufacturing method and technology of titanium balls, applied in chemical instruments and methods, titanium oxide/hydroxide, catalyst activation/preparation, etc., can solve problems such as unexpectable effect, difficulty in use, lack of activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The method for manufacturing titanium balls involved in the present invention will be described in more detail below through the following examples. In addition, the method for manufacturing titanium balls involved in the present invention is not limited by the following examples.

[0048]

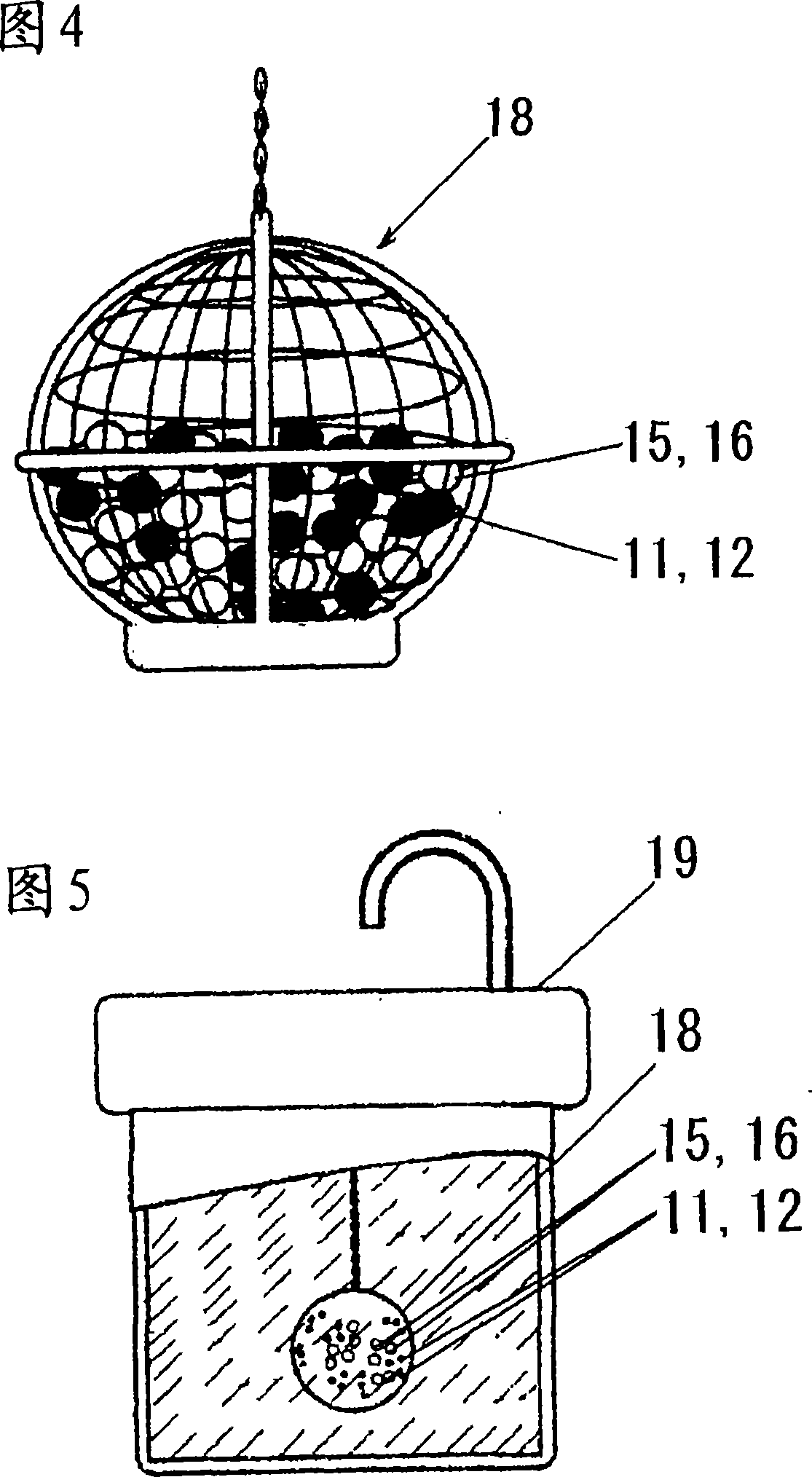

[0049] In the rotating container (capacity: 200 ml) made of metal titanium of the planetary ball mill (manufactured by Gokin Planetaring Co., Ltd.) shown in Fig. 6, put 100 alumina balls with a diameter of 8 mm and many holes on the surface, and put white titanium dioxide at the same time 2 g of powder (manufactured by Ishihara Sangyo Co., Ltd., ST-01, average particle diameter 7 nm) was sealed. Then, the planetary ball mill was operated to rotate the rotary container at 500 rpm. The spin time was 10 minutes, and the implementation sample was obtained.

[0050] The following experimental evaluations were performed on the following experimental samples.

[0051]

[0052] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com