Jet pump

A nozzle and channel technology, applied in jet pumps, pumps, non-displacement pumps, etc., can solve the problems of very sensitive position, blockage of coarse materials, unstable position of cold shock wave, etc., to achieve the effect of optimizing energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The same components are denoted by the same reference numerals in the specification.

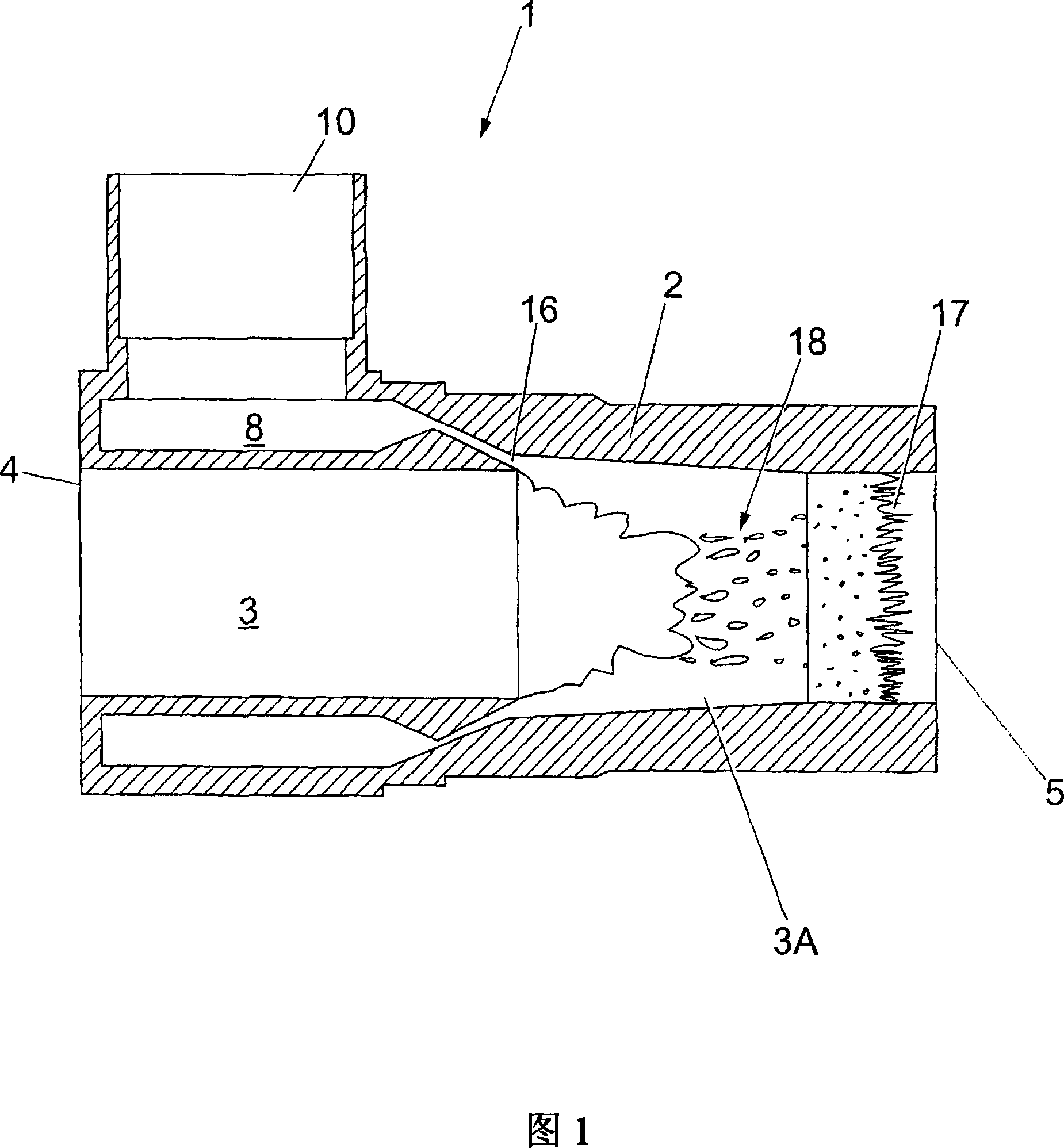

[0080] Referring to Figure 1 , there is shown a fluid mover 1 comprising a housing 2 defining a channel 3 providing an inlet 4 and an outlet 5, the channel 3 having a substantially constant circular cross-section.

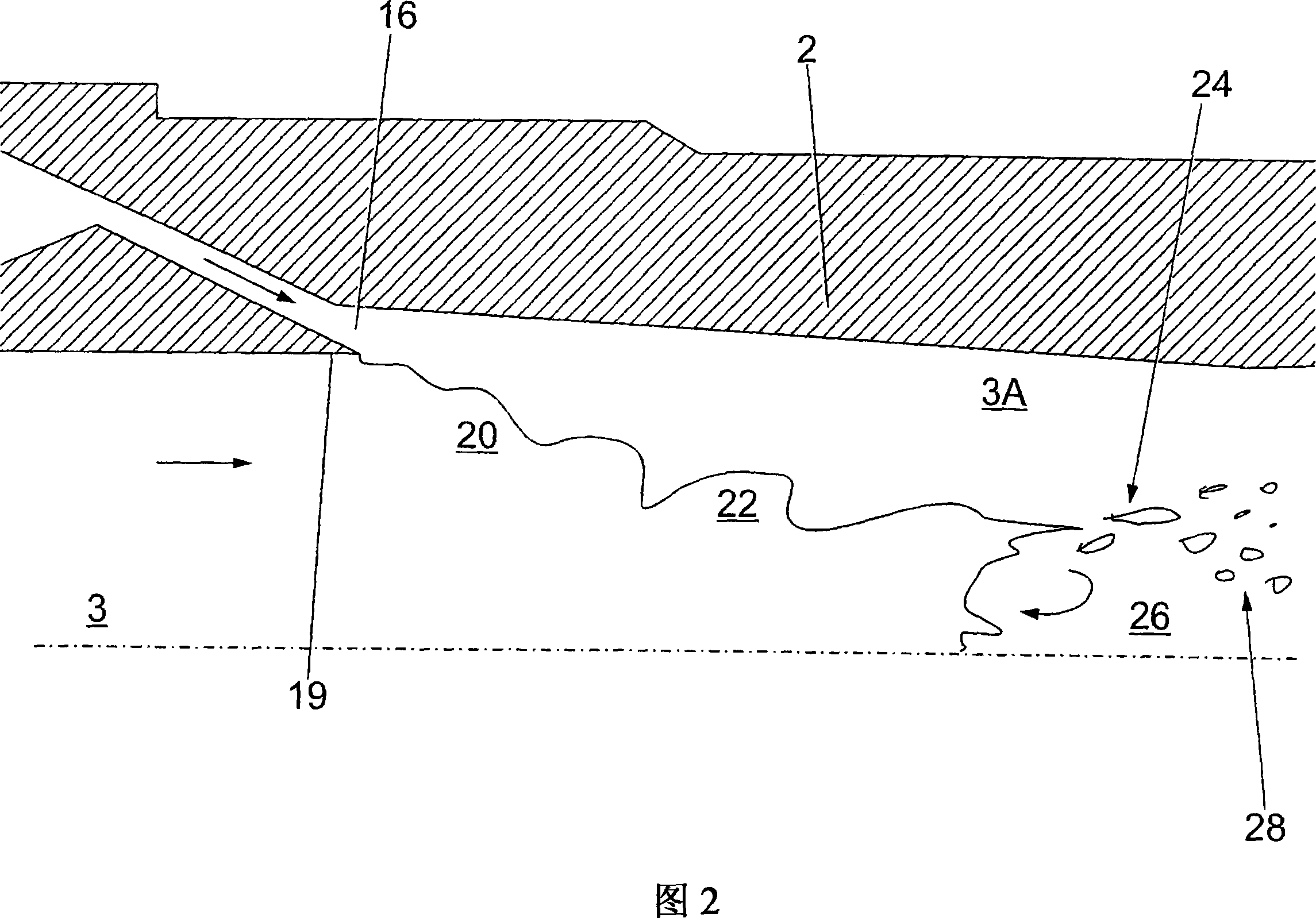

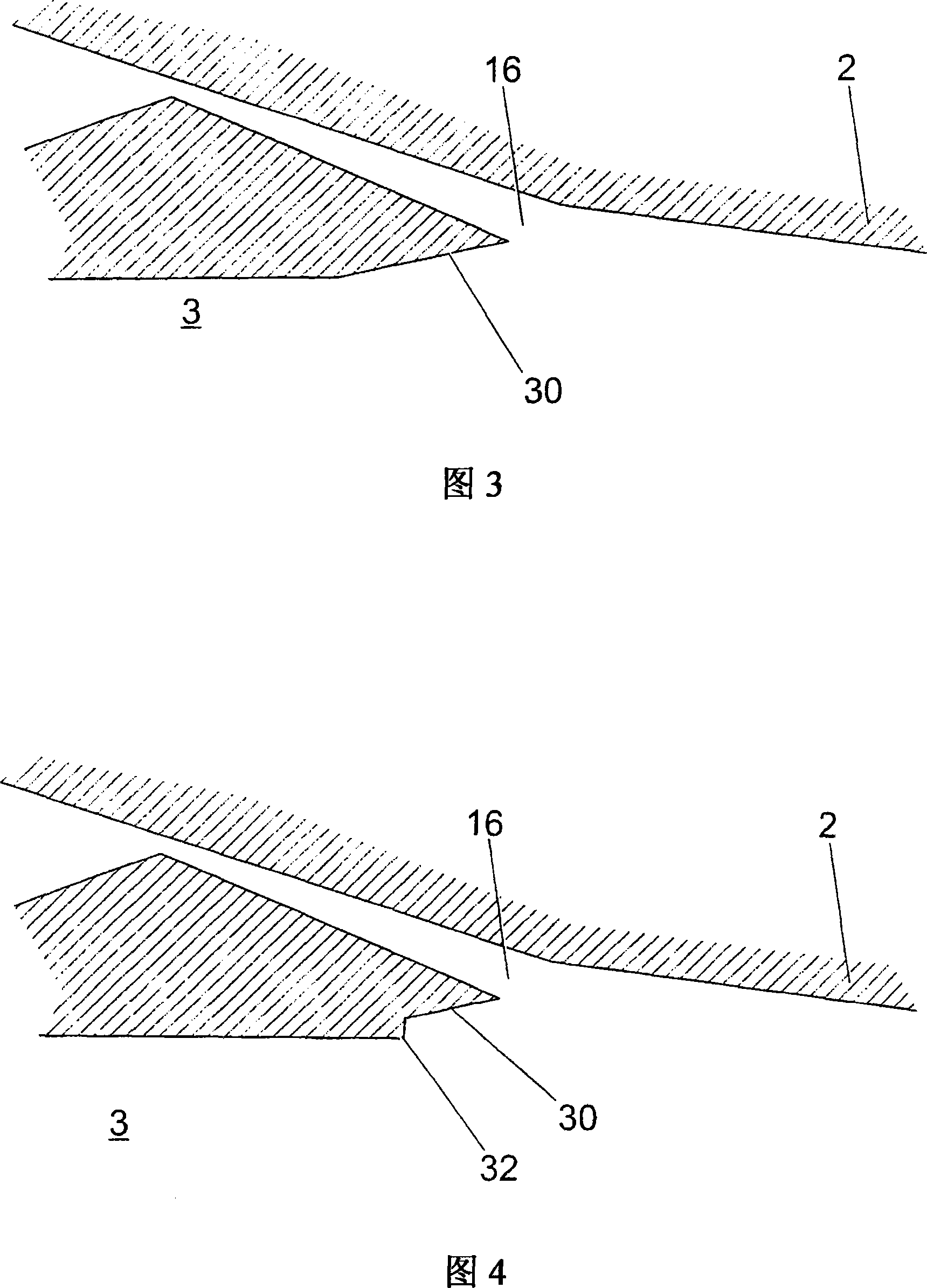

[0081] The housing 2 comprises a plenum 8 for introducing a carrier fluid, the plenum 8 being provided with an inlet 10 . The end of the plenum is tapered and defines an annular nozzle 16 . Nozzle 16 is in fluid communication with plenum 8 . The nozzle 16 is formed to produce a supersonic flow in use.

[0082] In operation, the inlet 4 is connected to a source of process or working fluid. Steam is introduced into the fluid mover 1 through the inlet 10 and the plenum 8 , causing a jet of steam to be ejected forward through the nozzle 16 . The steam ejected from the nozzle 16 interacts with the working fluid in the channel section serving as the mixing chamber (3A). In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com