Universal building-block cast-in-situs gypsum wall antiknock house and its construction

A gypsum wall and block technology, which is applied to walls, roofs, building components, etc., can solve the problem of high construction cost of earthquake-resistant housing, and achieve the effects of strong space work performance, large heat storage performance, and simple construction methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

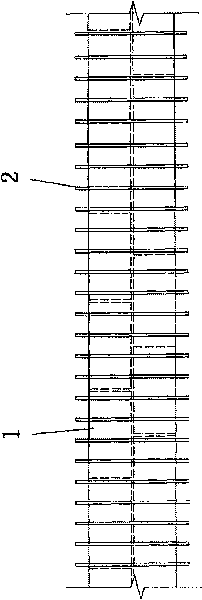

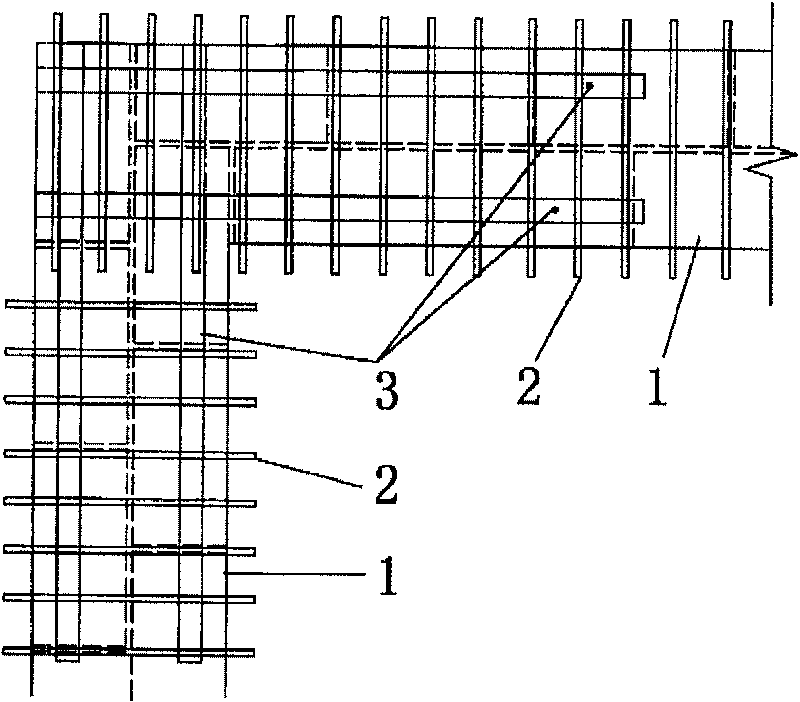

[0040] Embodiment 1, the universal block cast-in-place gypsum wall is a straight wall, including wall, inner wall and outer wall, and the wall is formed by alternating layers of universal blocks 1 and ribs 2. figure 1 As shown, the ribs 2 are vertically placed between the upper universal block 1 and the lower universal block 1 in a vertical direction perpendicular to the wall, and the inner and outer walls inside and outside the wall are cast-in-place made of gypsum slurry. The two ends of the bar 2 are placed in the inner wall and the outer wall, and there is cast-in-place gypsum slurry in the gap between the rib 2, the upper common block 1 and the lower common block 1.

Embodiment 2

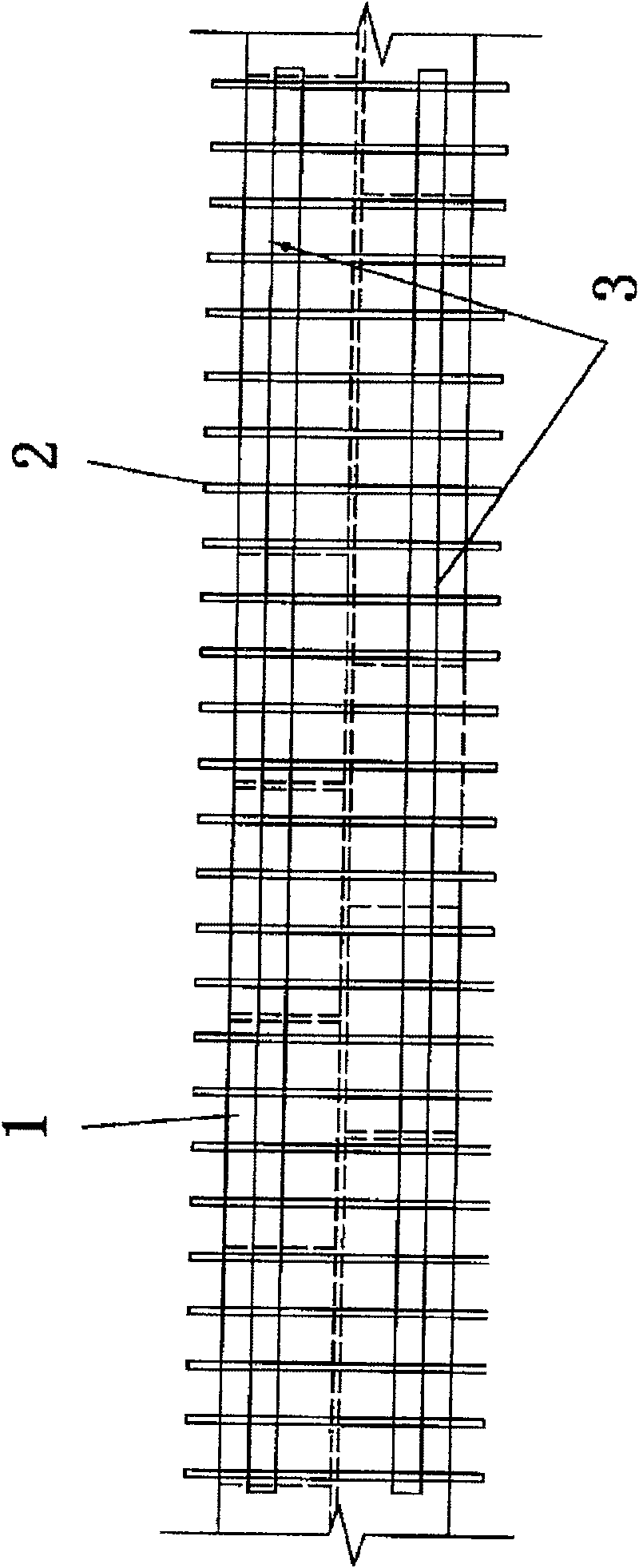

[0041] Embodiment 2, as attached figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that a horizontal tie bar 3 is placed along the wall between the ribs 2 of embodiment 2 and the upper general block 1 or / and the lower general block 1, There is cast-in-place gypsum slurry in the gaps between ribs 2, horizontal tie bars 3, upper common block 1, and lower common block 1, wherein the horizontal tie bars are made of glass fiber cloth, barbed wire, plastic straps and plant More than one of the stems, the plant stems can be plant stems such as cotton stems, reeds, wattles, wooden strips, and bamboo strips.

Embodiment 3

[0042] Embodiment 3, as attached figure 2 As shown, the difference between embodiment 3 and embodiment 2 is that the horizontal tie bar 3 of embodiment 3 adopts steel wire mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com