Arc spring cradles on shoulders

A spring hanger, arc-shaped technology, applied in the direction of pipe supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

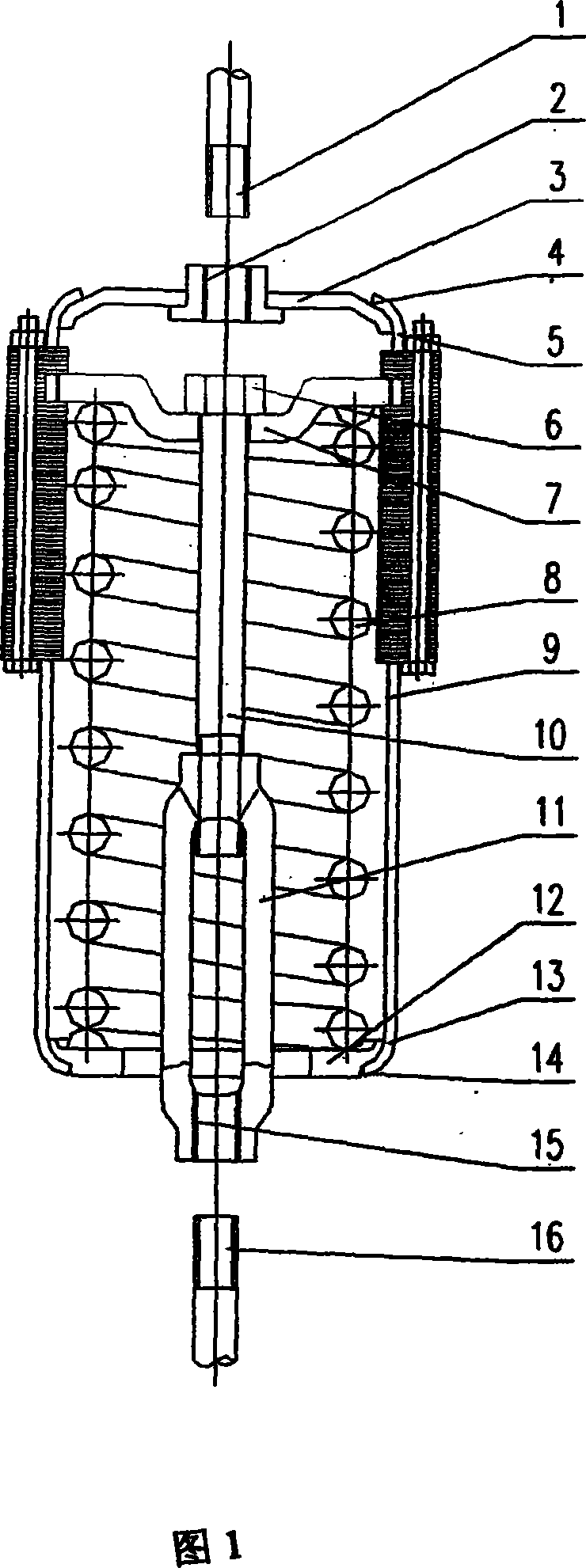

[0010] Embodiment 1: The shell is suspended, and the threaded hanging hole is connected to the curved spring hanger of the shoulder

[0011] Referring to Fig. 1, Fig. 1 is a spring hanger with a threaded hanging hole connected to a curved shoulder. It mainly consists of a cylinder body 9, a spring 8, a spring pressing plate 7, a top plate 3 and a bottom plate 12. The spring 8 and the spring pressing plate 7 are enclosed in the cavity surrounded by the cylinder body 9 , the top plate 3 and the bottom plate 12 . Spring pressing plate 7 places spring 8 tops. A suspender 10 with a bolt head 6 at one end is hung on the spring pressure plate 7, the spring 8 passes through the middle of the suspender 10, and the other end of the suspender 10 is connected with a screw 11 with a threaded hole 15 and can be connected with the lower screw 16, The lower end of the turnbuckle screw 11 passes through the bottom plate 12 . The center of the top plate 3 is provided with a threaded hole 2, ...

Embodiment 2

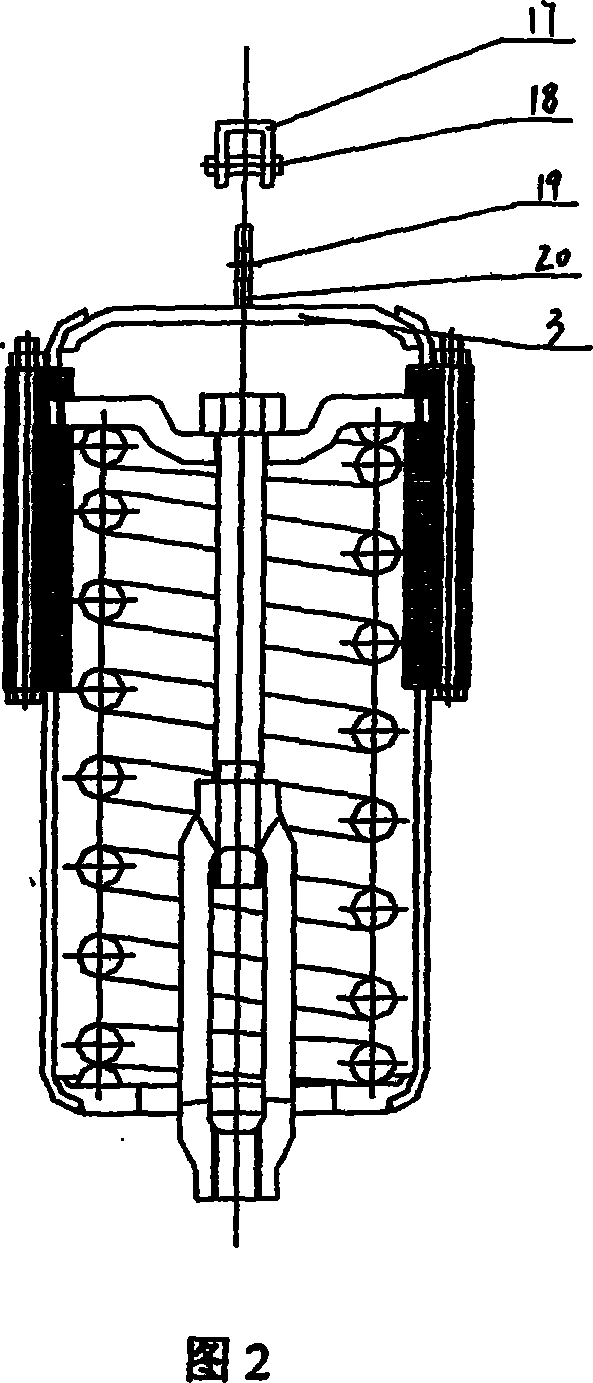

[0016] Embodiment 2: Shell suspension, single-ear suspension plate connected to a spring hanger with arc-shaped shoulders

[0017] Referring to FIG. 2 , the difference between the structure of FIG. 2 and FIG. 1 is that the top plate 3 is provided with a lifting lug 20 with a hole 19 to facilitate connection with the double lifting lug 17 with a pin shaft 18 .

Embodiment 3

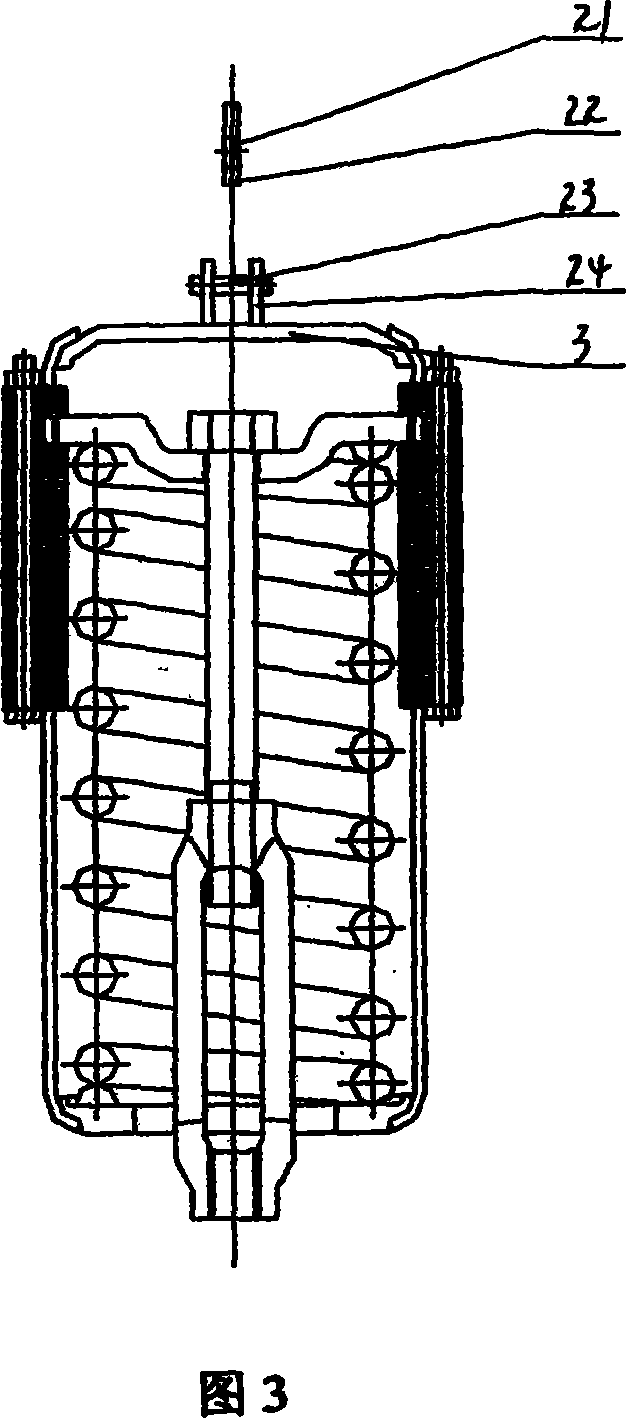

[0018] Embodiment 3: The shell is suspended, the double-ear hanging plate is connected to the spring hanger with arc-shaped shoulders

[0019] Referring to FIG. 3 , the difference between the structure of FIG. 3 and FIG. 1 is that the top plate 3 is provided with double lugs 24 with pins 23 to facilitate the connection of the lugs 22 with holes 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com