Combined type dust collecting anode board

An anode plate, combined technology, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems of low adsorption capacity of charged soot particles, can not meet the ideal requirements, large electrostatic precipitator, etc., to reduce vibration and dust removal. Effects of period, volume reduction, and collection capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

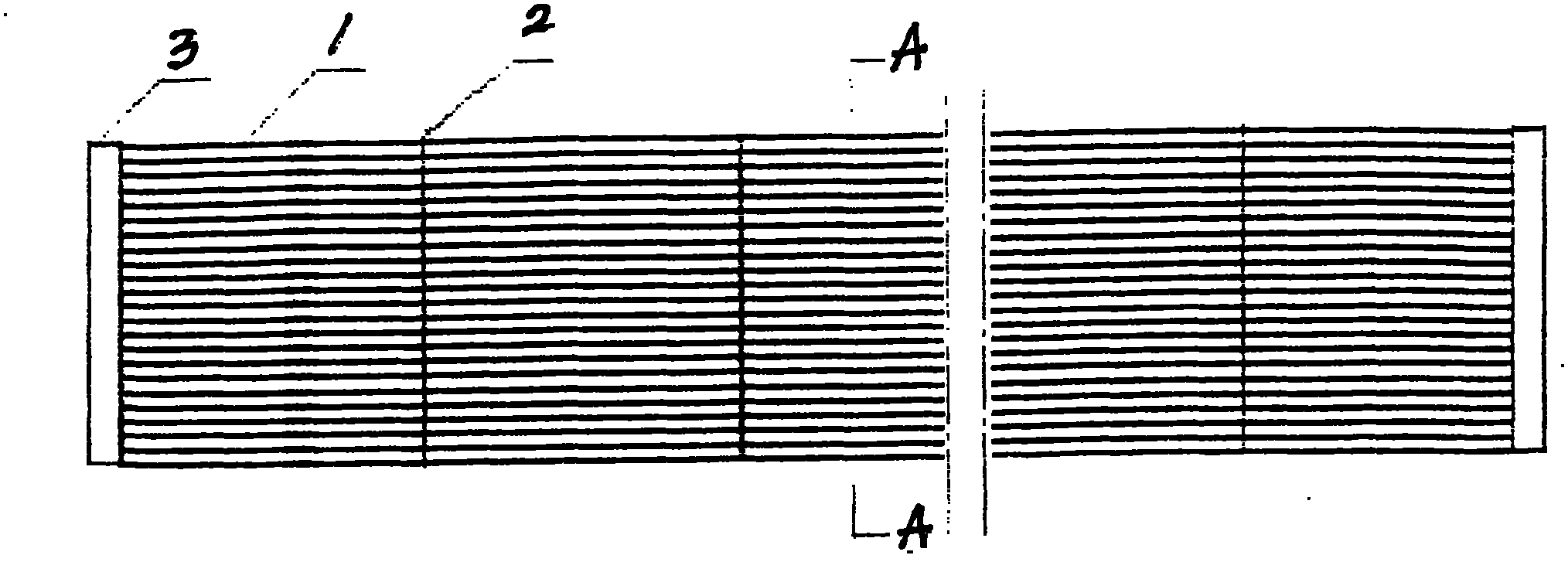

[0015] exist figure 1 Among them, the metal dust-collecting pole strips with equal length, equal width, and the same geometric shape are arranged at equal intervals and parallel, and their two ends are respectively fixed by metal end plates, and the middle sections are connected and fixed by metal positioning strips. Made into a combined dust-collecting anode plate.

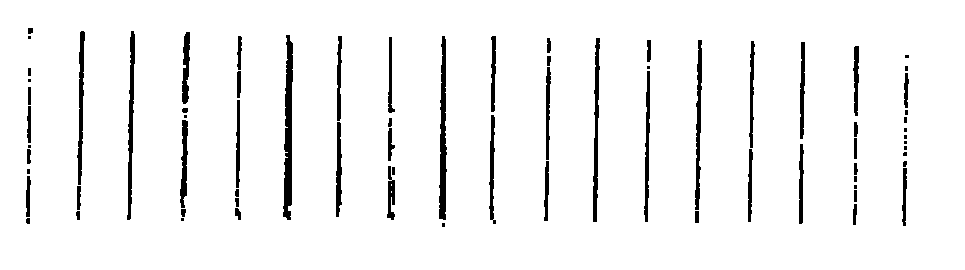

[0016] exist figure 2 In the middle is the A-A sectional view of the implementation example of using slat-shaped dust-collecting pole slats, which are equally spaced and arranged in parallel.

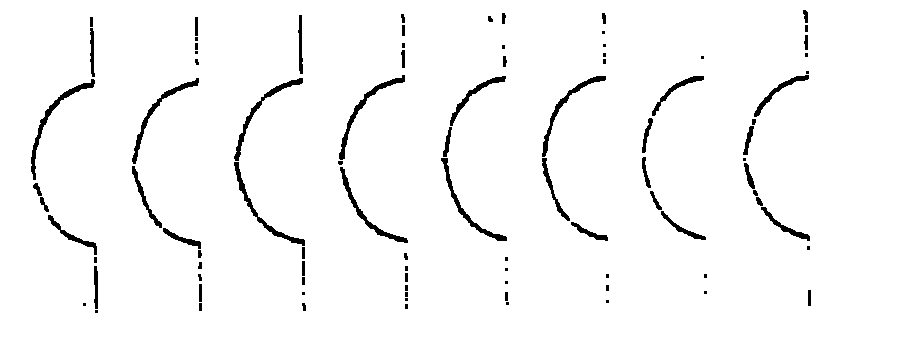

[0017] exist image 3 In the middle is the A-A sectional view of the implementation example of U-shaped dust-collecting pole strips, which are equally spaced and arranged in parallel.

[0018] exist Figure 4 In the middle is the A-A sectional view of the implementation example of V-shaped dust-collecting pole strips, which are equally spaced and arranged in parallel.

[0019] exist Figure 5 In the middle is the A-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com