Photosensitive film used for holographic recording and manufacturing method

A technology of thin film materials and photosensitive polymers, which is applied in the field of photosensitive materials, can solve the problems of photosensitive plates that need to be produced on-the-go, low reflection efficiency, and short storage life, and achieve the effects of small impact, high reflection efficiency, and long storage life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Under the red safety light with wavelength greater than 600nm, the film-forming agent polyvinyl acetate butyl acrylate acrylic acid terpolymer, 6 grams (67.3wt%), monomer N-vinyl carbazole 1.2 grams (13.5wt%) %), monomer tricyclodecane dimethanol diacrylate 1.0 gram (11.2wt%), photoinitiator 2,4, 0.2 gram (2.2wt%) of 6-triphenyl imidazolyl doublet, photosensitizer two Ethylamino-benzylidene cyclopentanone 0.05 gram (0.57%), chain transfer agent 2-mercaptobenzothiazole 0.15 gram (1.68wt%), ultraviolet absorber 2-hydroxyl-4-methoxybenzophenone 0.05 gram (0.56wt%), nonionic surfactant Fluorad FC-44300.06 gram (0.67wt%), plasticizer diethyl sebacate 0.2 gram (2.2wt%) adds mixed solution (butanone: dichloro Methane:methanol=5:1:1, weight ratio), the weight solid content is 10%, stirred at room temperature until dissolved, the measured viscosity is 10-12cp (25°C), filtered to obtain photosensitive coating A, ready for use;

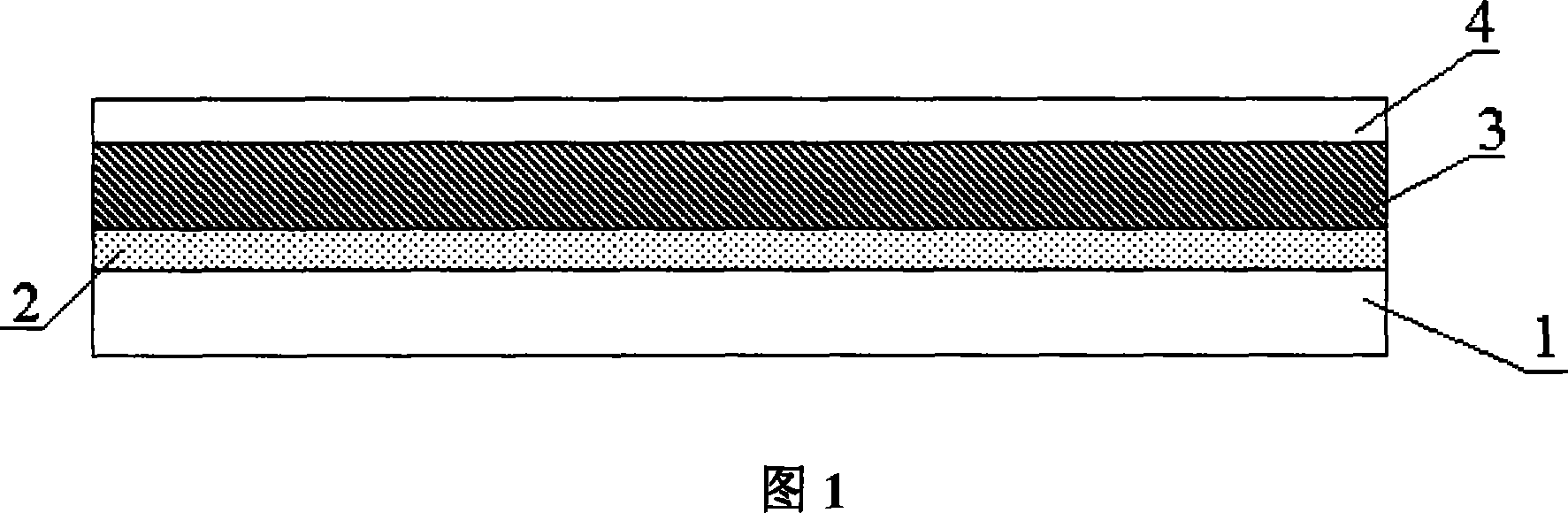

[0053] Choose 50 μm high-transparency PET film as ...

Embodiment 2

[0058] Under the red safety light with wavelength greater than 600nm, the blend of film-forming agent polyvinyl butyral and cellulose acetate, 2.5 grams (30.5wt%), monomer N-vinylcarbazole 2.8 grams (34.1wt%) %), 1.7 grams (20.7wt%) of diacrylate of bisphenol A of monomer ethoxylation, 0.54 grams (6.6wt%) of photoinitiator isobutyl benzoin ether, photosensitizer Michler's ketone 0.12 grams (1.46wt%), chain transfer agent 2-mercaptobenzothiazole 0.23 grams (2.8wt%), UV absorber 2-hydroxyl-4-methoxybenzophenone 0.06 grams (0.73wt%), non-ionic surface Activator methoxypolyethylene glycol 0.06 gram (0.73wt%), plasticizer diethyl sebacate 0.2 gram (2.4wt%) is added to mixed solution (butanone: dichloromethane: methyl alcohol=5: 1 : 1, weight ratio), the weight solid content is 32.4%, stirred at room temperature until dissolved, the measured viscosity is 28.3cp (25°C), filtered to obtain photosensitive coating A, stand-by;

[0059] Select a 36 μm high-transparency PET film as the b...

Embodiment 3

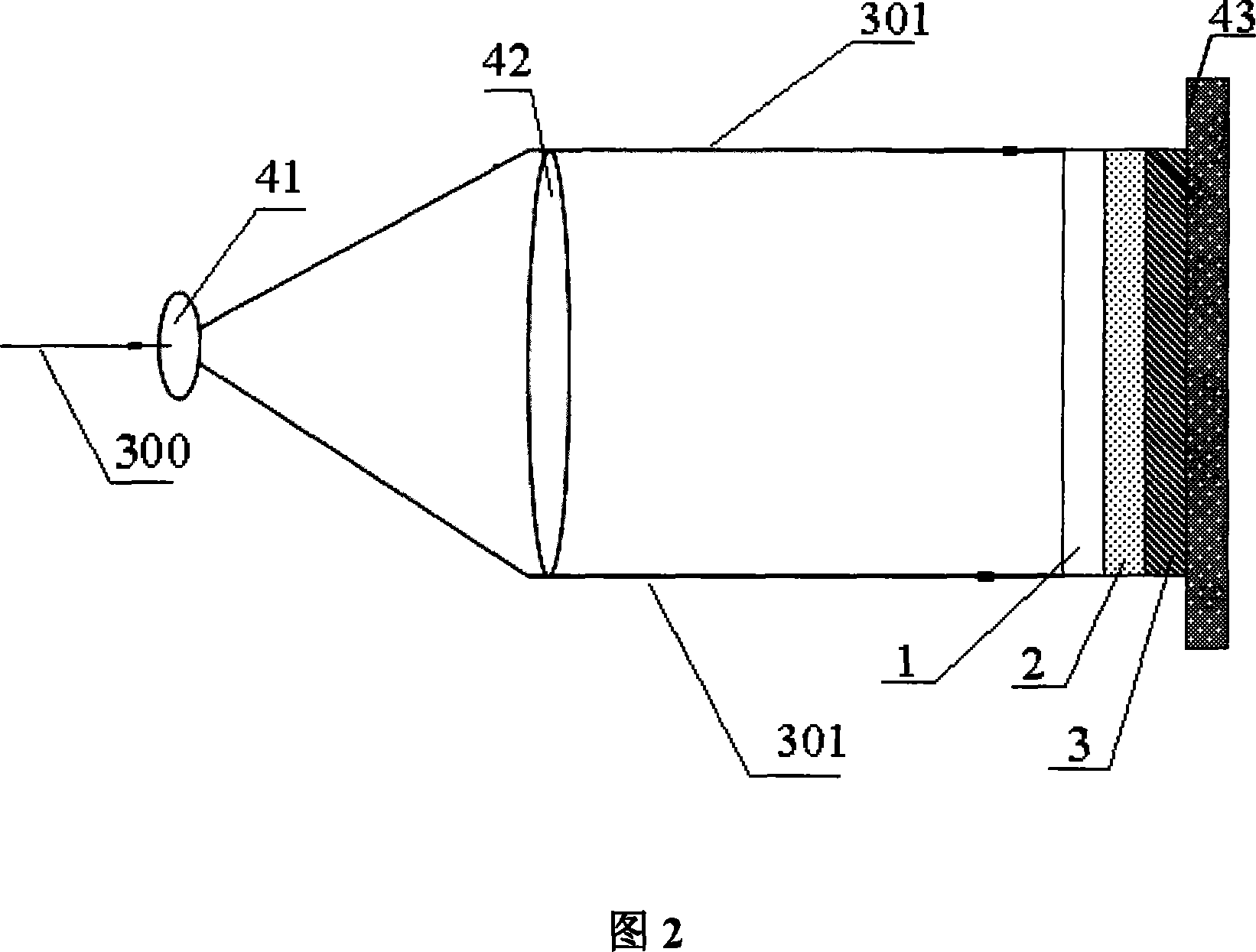

[0063] The evaluation of photosensitive polymer film C can refer to the method in Figure 2, and the holographic imaging recording can be performed on the photosensitive polymer film through coherent light "on-axis" recording technology.

[0064] The above-mentioned photosensitive polymer film C is cut into sheets of 30*30 mm, and after the surface protection film (4) is peeled off, it is evenly pasted on the reflector (43). With an argon ion laser (514nm) as the light source, the beam (300) passes through a beam expander (41) with a pinhole filter and an aspherical collimating convex lens (42) to form a parallel beam (301) and radiates on the photosensitive polymer film C , the flat light (301) is incident from the base film (1), passes through the buffer layer (2) and the photosensitive paint layer A (3) and reaches the mirror (43), and is reflected back to the photosensitive paint layer A (3) in the original path to form a record raster. Radiation diameter is 15mm. Reflect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap