Controller

一种控制装置、控制对象的技术,应用在程序控制、自适应控制、电动控制器等方向,能够解决力控制增益性能差、无法进行插入、力控制性能差等问题,达到通用性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

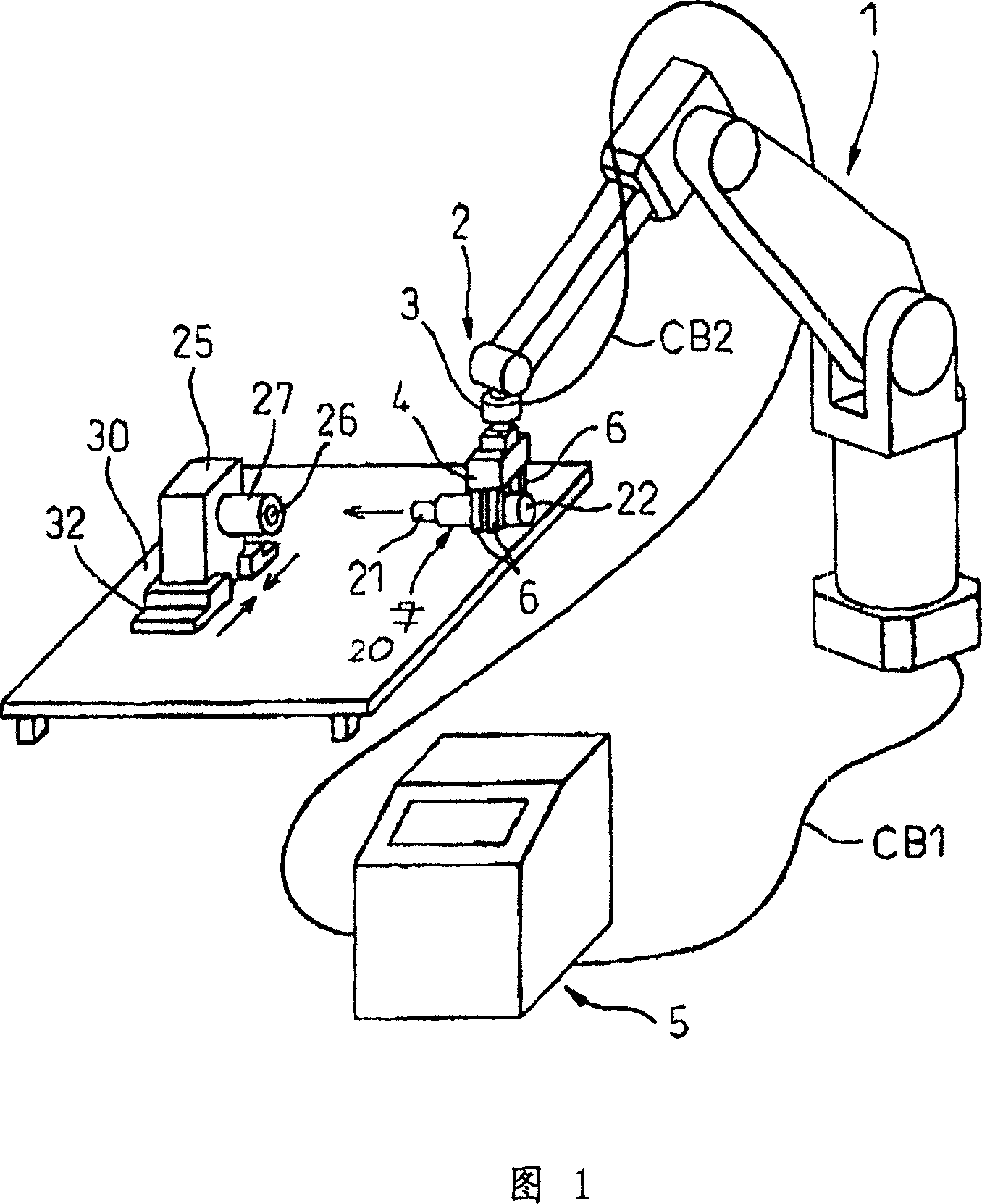

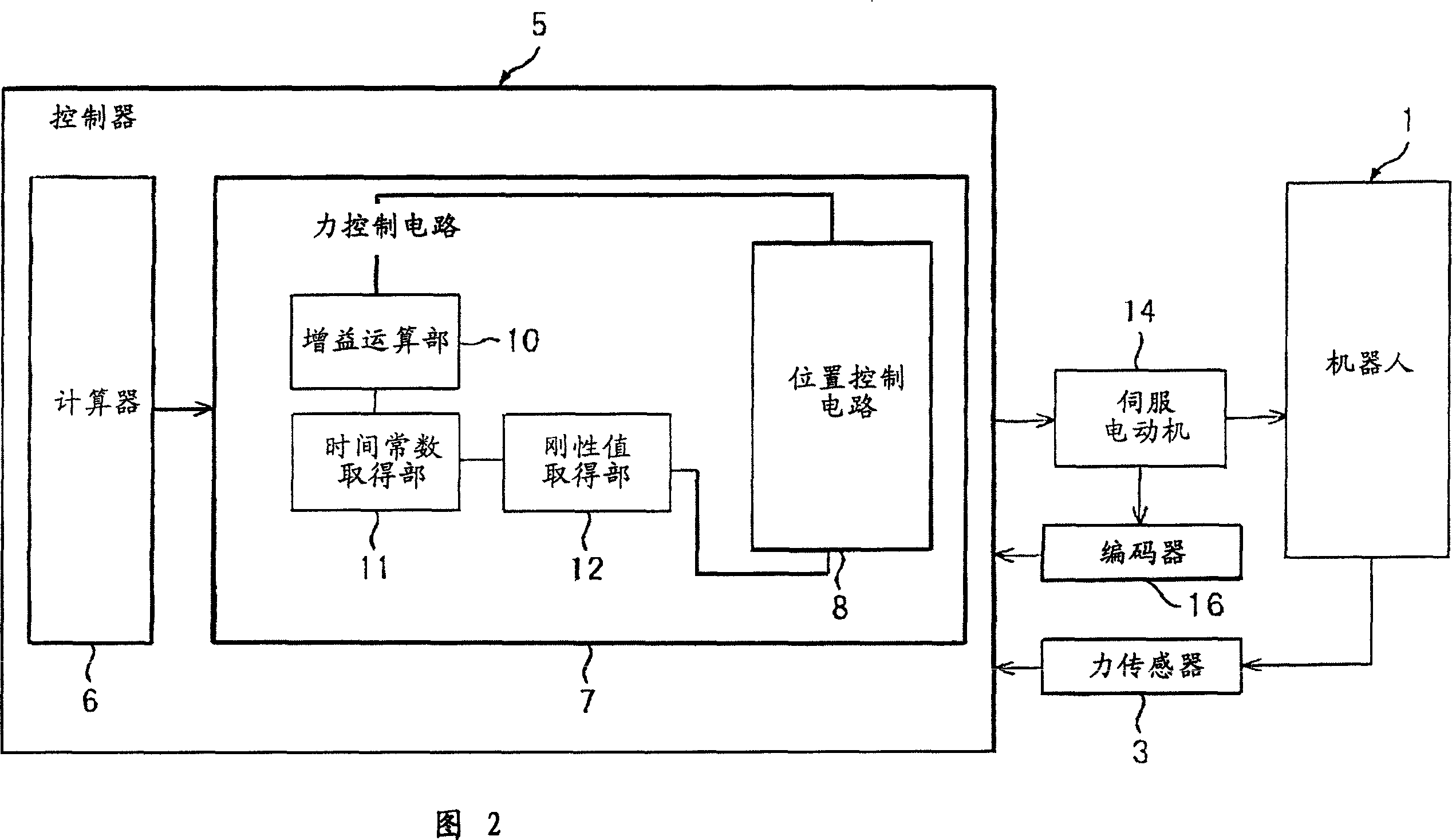

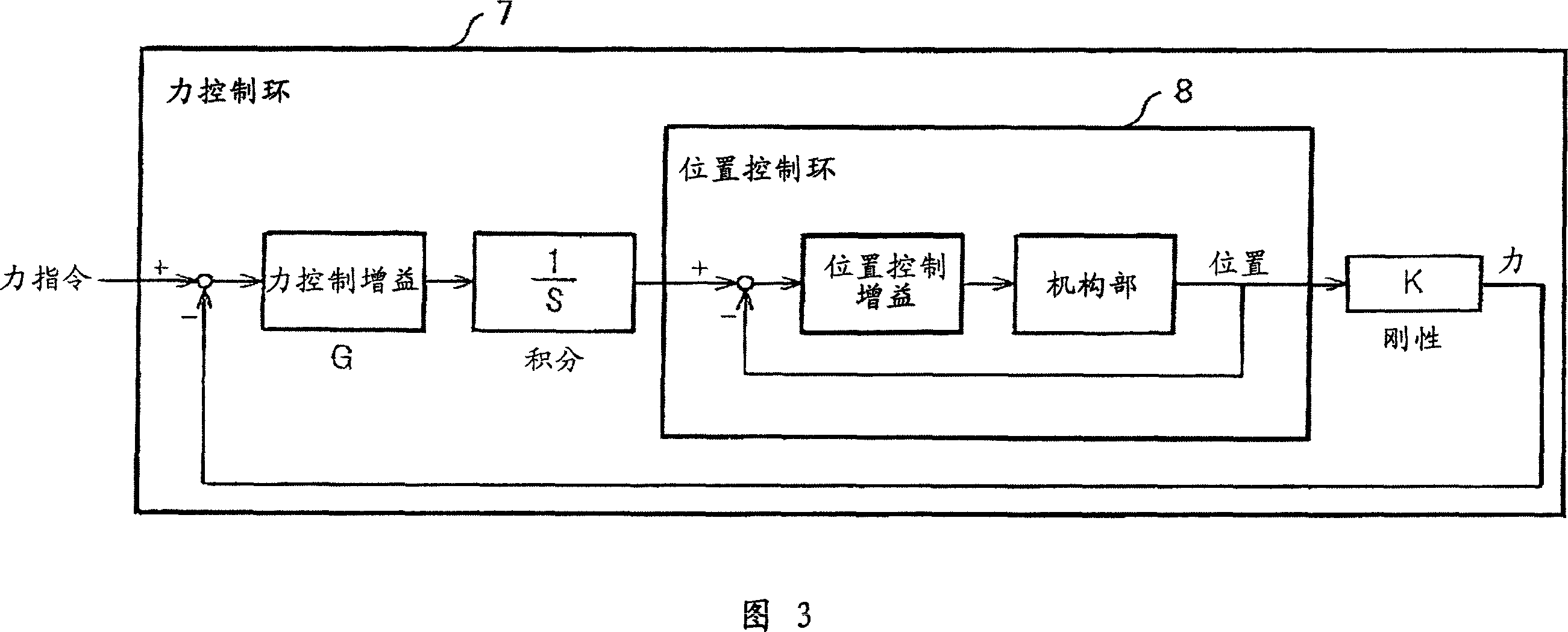

[0027] Next, the robot control device (control device) of the present invention will be described with reference to the drawings. Figure 1 shows a six-axis robot that translates three axes and rotates three axes as the control object. Control devices for force controlling the illustrated robot etc. are broadly classified into a system having a position control circuit connected in series inside the force control circuit and a system having a position control circuit connected in parallel outside the force control circuit. The control device of the present invention ( FIG. 2 ) can control the force of the contact state between the robot (control object) and the target workpiece by targeting a system (see FIG. 3 ) having a position control circuit connected in series inside the force control circuit, and The force control gain can be automatically set according to the time constant (delay) of the position control circuit and the mounting rigidity of the robot and target workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com