Making method for the image module with the sensor directly connected and encapsulated together with the soft board

A technology of an image module and a manufacturing method, which is applied in image communication, semiconductor devices, components of color TVs, etc., can solve the problems of complicated process, limitation of image modules, reduction of packaging height, etc., and achieves good heat dissipation effect, Height reduction, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

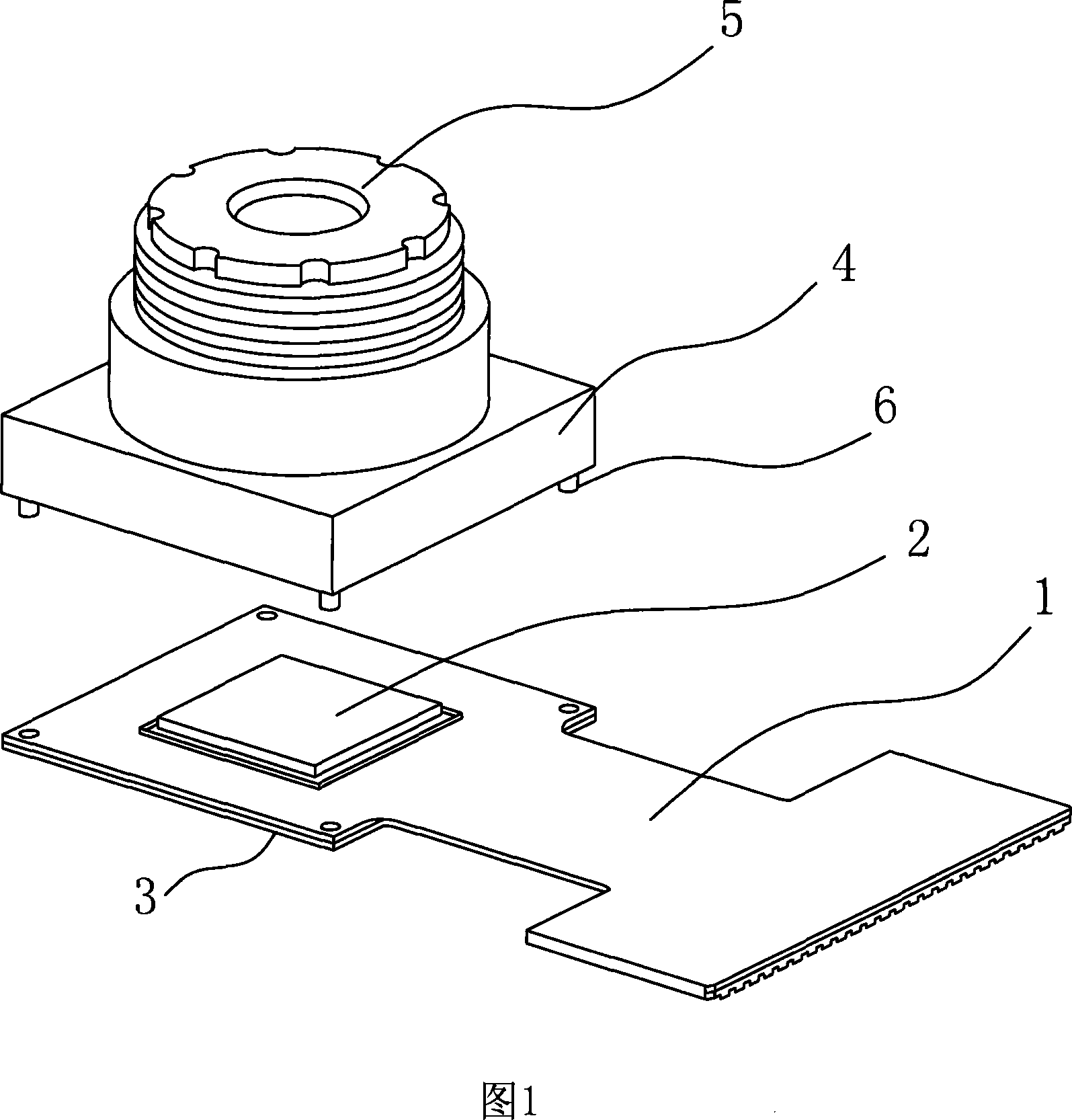

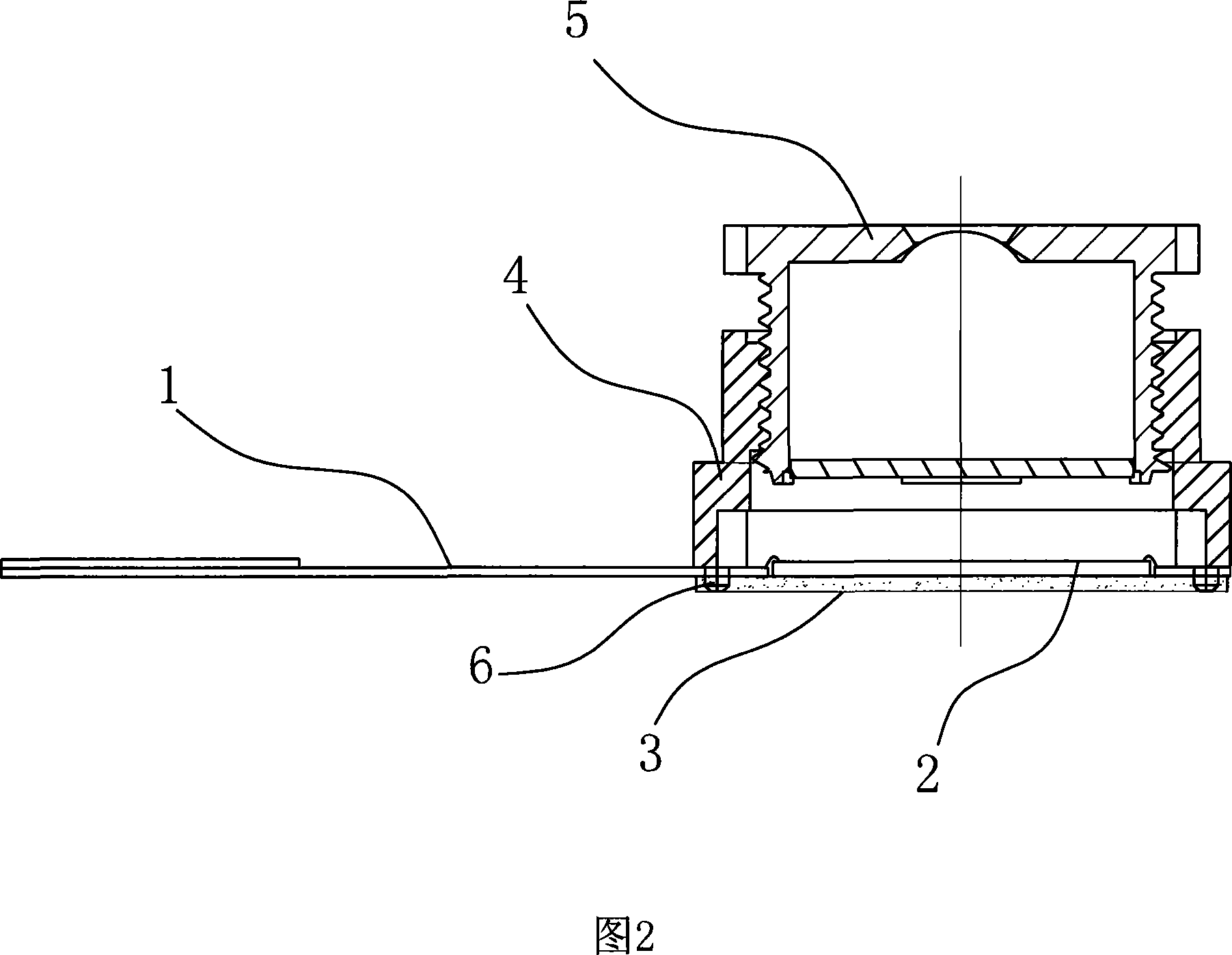

[0020] Embodiment 1: A method for manufacturing an image module in which an image sensor is directly connected to a flexible board and packaged, comprising the following steps:

[0021] Open a window on the soft board corresponding to the installation position of the image sensor chip, take a reinforcing steel plate that matches the size of the image module seat, and fix it on the back side of the opening of the soft board with adhesive;

[0022] Place the ground and cut image sensor chip in the hole of the soft board (upper sheet), fix the connection with the reinforcing steel plate with an adhesive, bake to cure the adhesive; make wires to connect the pins of the image sensor chip to the soft board The corresponding circuit is electrically connected;

[0023] Finally, the base body and the lens unit are installed to realize the packaging of the image module.

[0024] Referring to accompanying drawings 1 and 2, it is a schematic diagram of the structure of the image module p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com