Method and apparatus for bending

A bending processing and bending technology is applied in the field of bending processing and its devices to achieve the effects of improving processing efficiency, reducing burden and preventing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Hereinafter, the present invention will be described in terms of embodiments with reference to the drawings.

[0090] A. The first invention

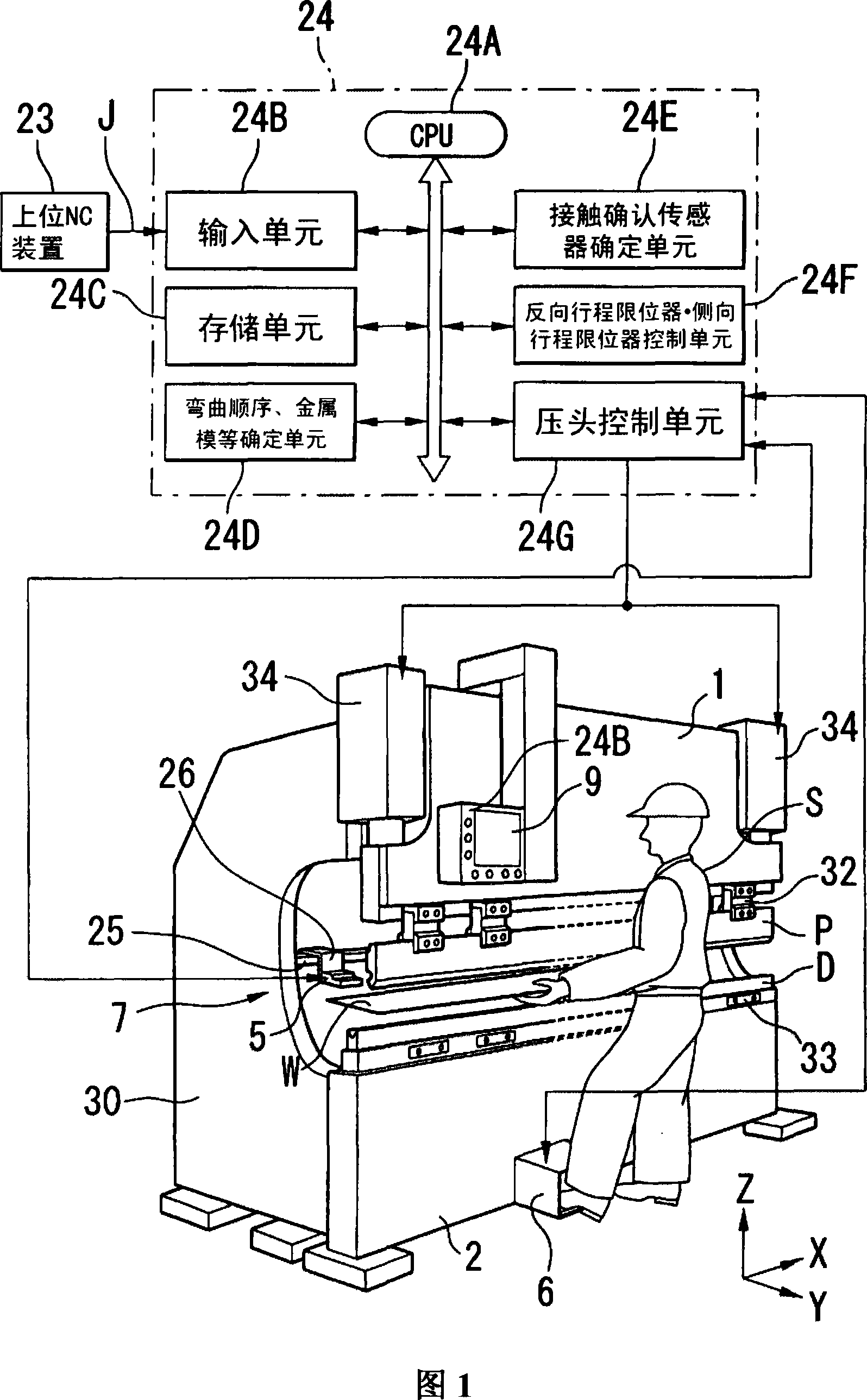

[0091] FIG. 1 shows an embodiment of the first invention of the present invention, and the illustrated bending device is, for example, a plate bender.

[0092] The bending machine is provided with side plates 30 on both sides of the machine body. On the top of the side plates 30, an upper workbench 1 as a pressure head is installed through, for example, a hydraulic cylinder 34. On the upper workbench 1, pass through the middle The plate 32 is fitted with punches P.

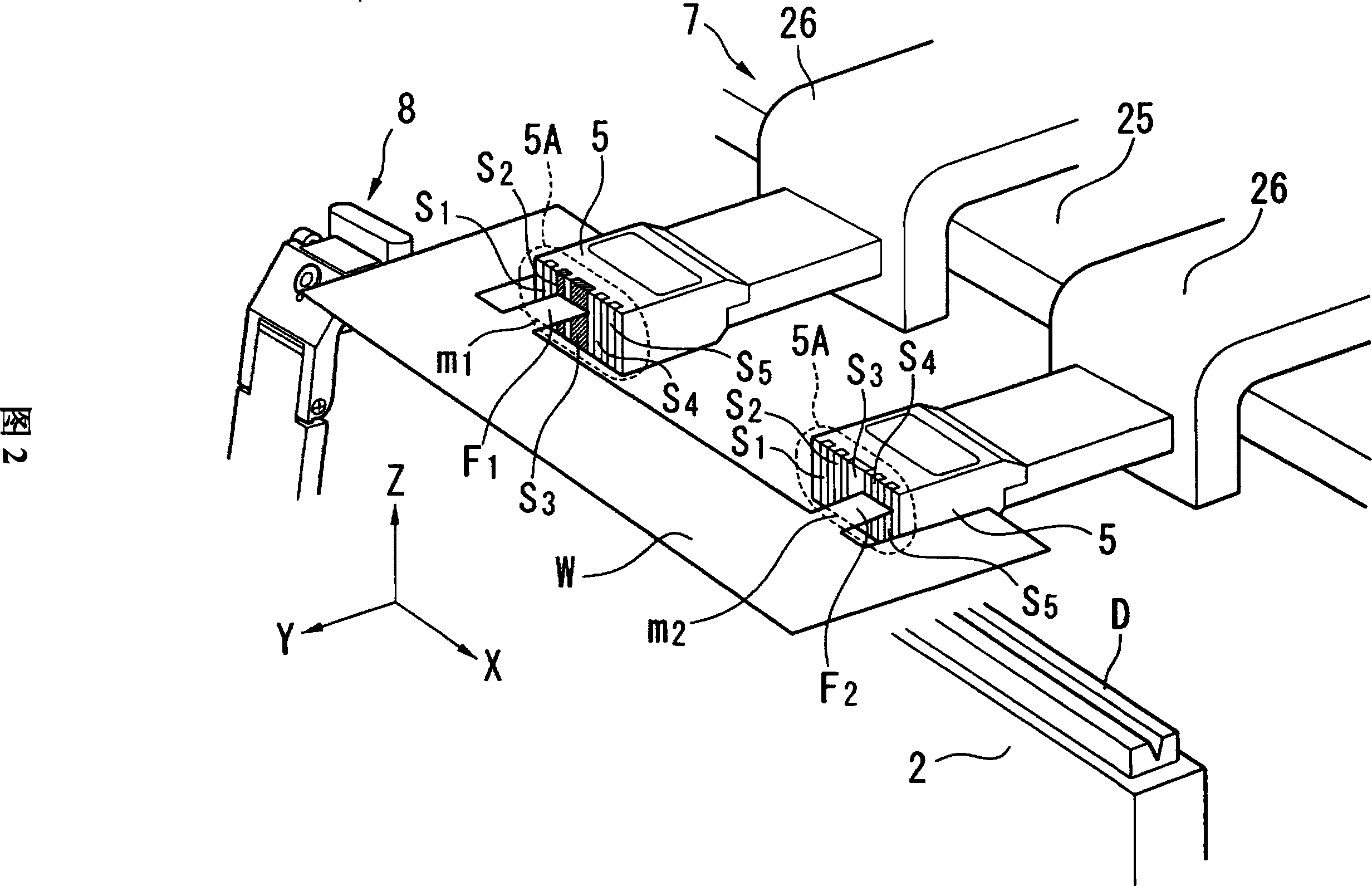

[0093] In addition, the lower table 2 is disposed under the side plate 30, and the mold D is attached to the lower table 2 through the holding plate 33. At the same time, a side table 2 is freely movable in the left-right direction (X-axis direction). The stroke stopper 8 ( FIG. 2 ) positions the workpiece W in the left-right direction.

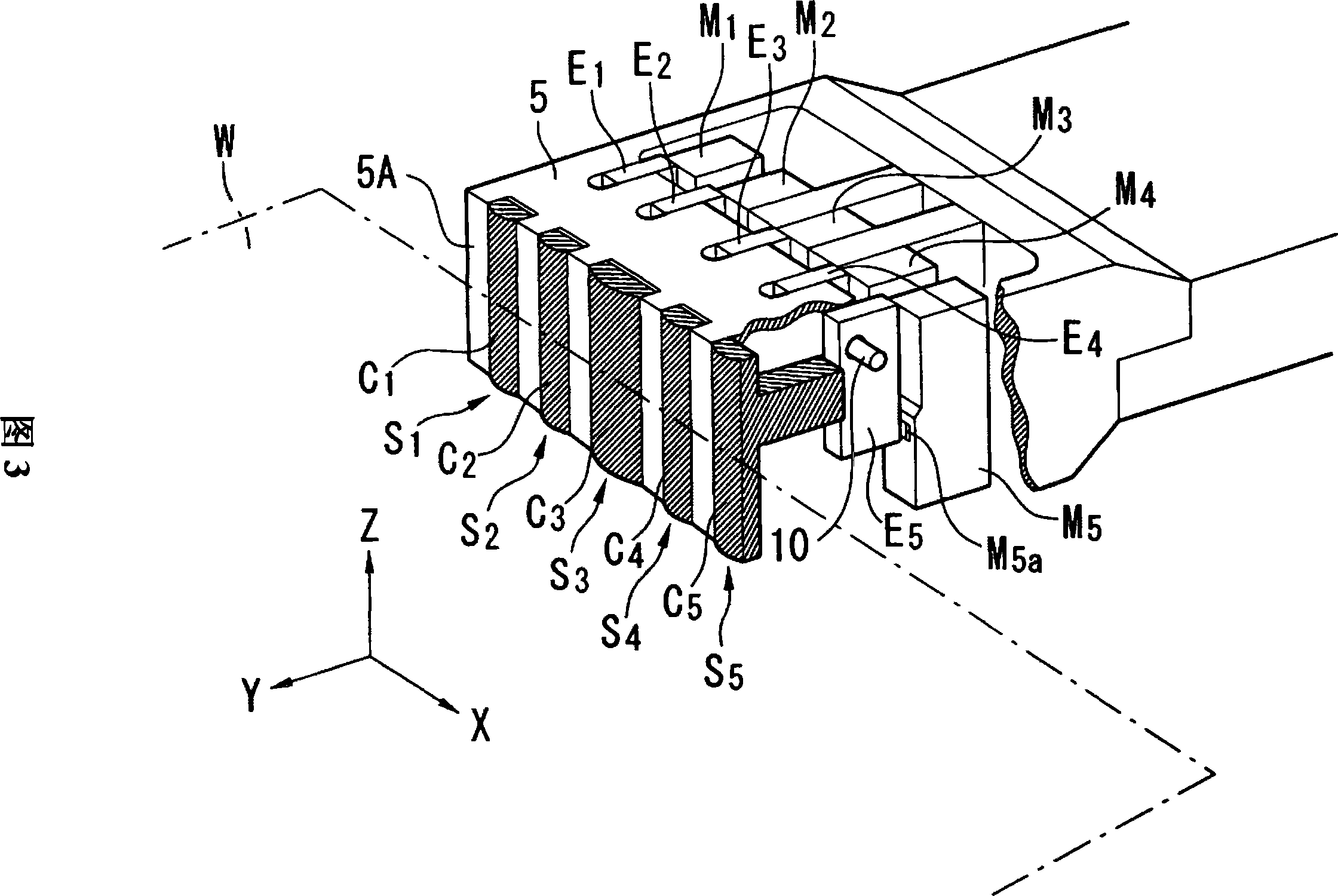

[0094] That is, the bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com