Method for operating extrusion plants for extruding thermoplastics

A technology for thermoplastics and extrusion devices, applied in the field of extrusion devices for extruding thermoplastics, can solve problems such as thickness fluctuations of melts, and achieve the effect of simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

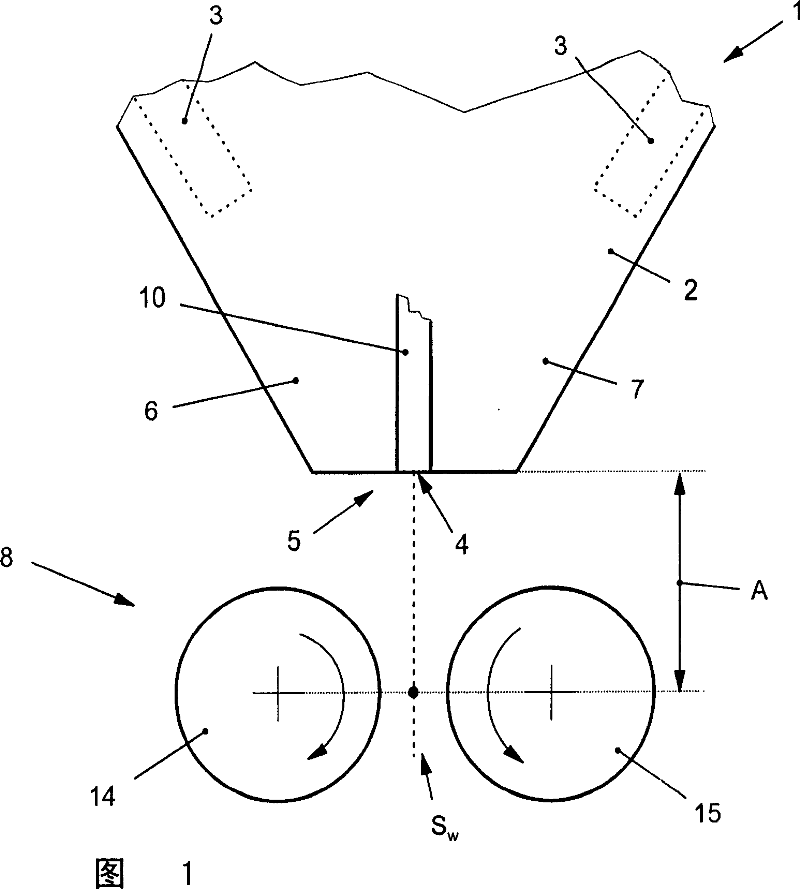

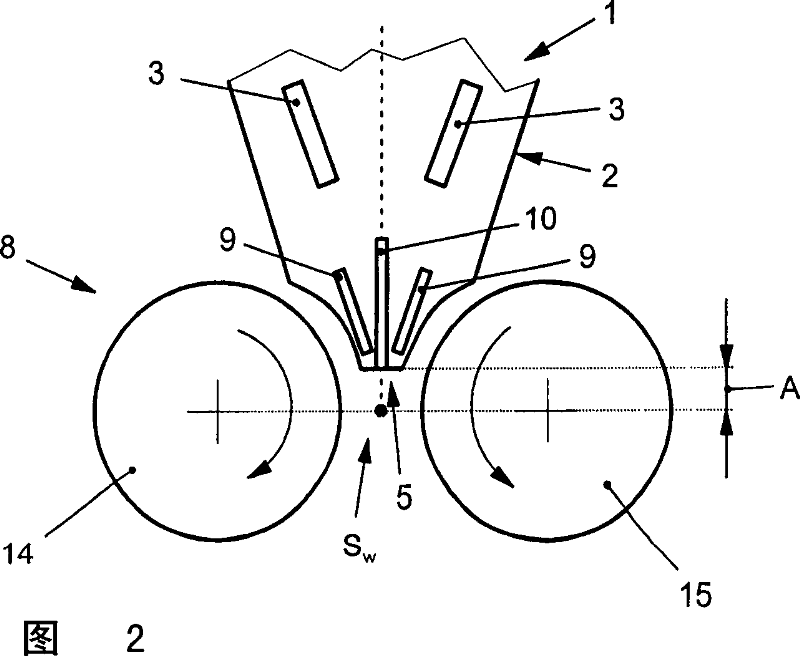

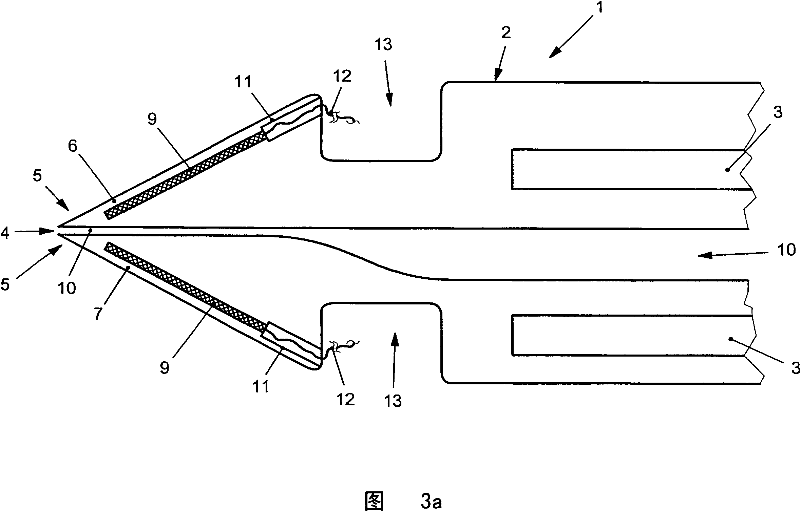

[0032] According to FIG. 1 , a conventional wide-slit nozzle 1 has a nozzle body 2 which can be heated by a conventional heating device 3 in order to produce extruded plastic material from a nozzle gap 4 in an extrusion device.

[0033] Here, the nozzle body 2 is subdivided, in particular in an outlet region 5 and a nozzle channel 10 , into lip elements 6 , 7 , wherein the lip parts 6 , 7 can be designed as rigid and / or flexible lips. Shaped elements 6,7.

[0034] Here, these lip elements 6, 7 or only one lip element 6 or 7 have some adjustment devices not shown in detail here, such as "fast-gap" adjustment devices or similar adjustment devices, so that automatic The nozzle gap is adjusted mechanically or mechanically with respect to the thickness of the nozzle gap. The adjusting device is used to quickly adjust the thickness of the outflow region of the nozzle element.

[0035] A disadvantage of conventional wide-slit nozzles is that the actual influence on the thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com