Barrel washing machine having magnetic rheologic active vibration damper

A technology of active shock absorbers and drum washing machines, which can be applied to other washing machines, springs/shock absorbers, household appliances, etc., and can solve the problems of limited vibration damping effect and poor real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

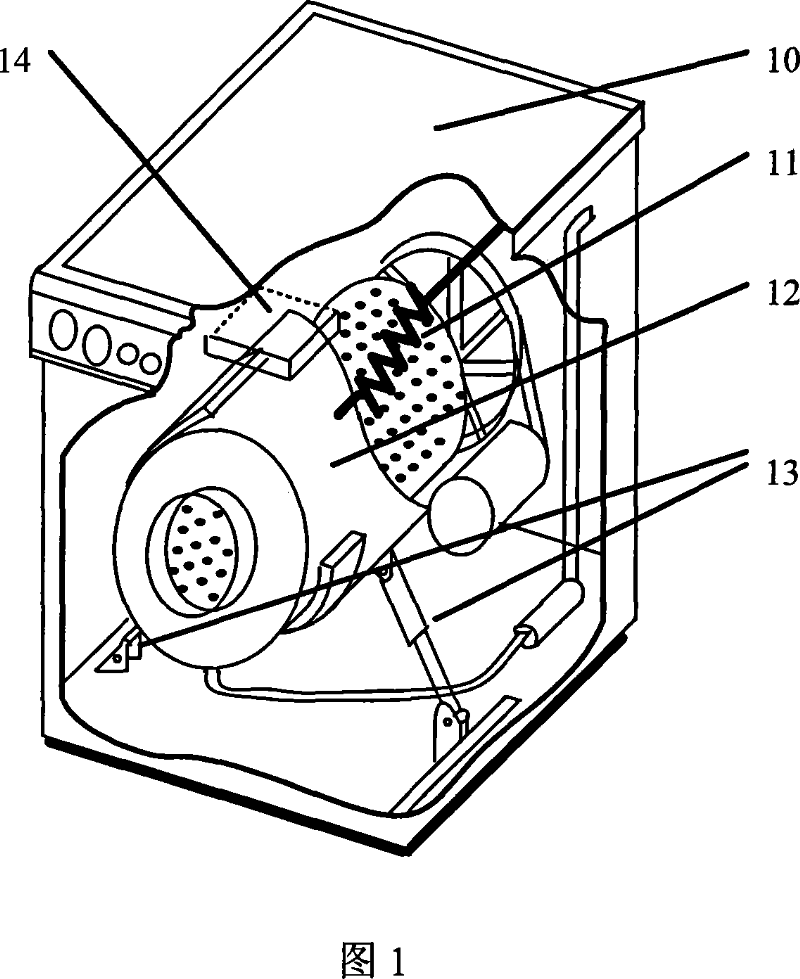

[0027] Embodiment 1 is a drum washing machine equipped with two magneto-rheological active shock absorbers. When the internal space of the drum washing machine is limited or the maximum load capacity of the washing machine is relatively small, two shock absorbers are installed under the washing drum, and the two shock absorbers are symmetrically distributed as shown in Fig. 1 .

Embodiment 2

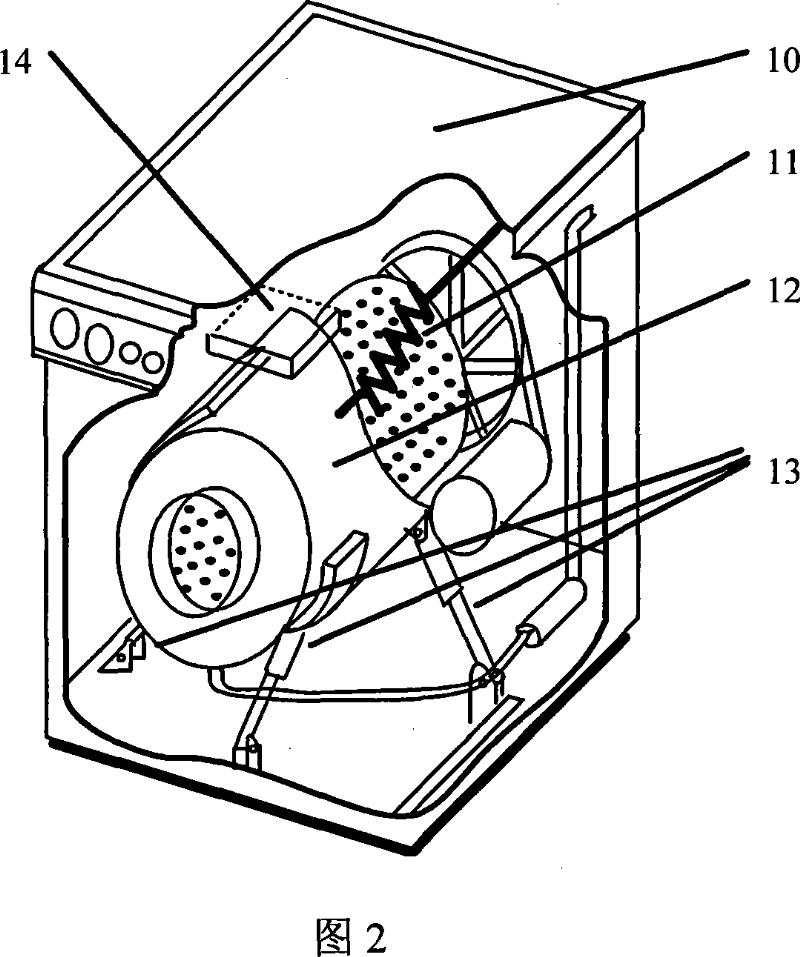

[0028] Embodiment 2 is a drum washing machine equipped with three magneto-rheological active shock absorbers. It is generally applied to a drum washing machine with a medium maximum load capacity. Three shock absorbers are installed under the washing tub, and the three magnetorheological active shock absorbers intersect to form a triangular platform, that is, the axes of the three magnetorheological active shock absorbers coincide with the three edges of the triangular platform respectively.

Embodiment 3

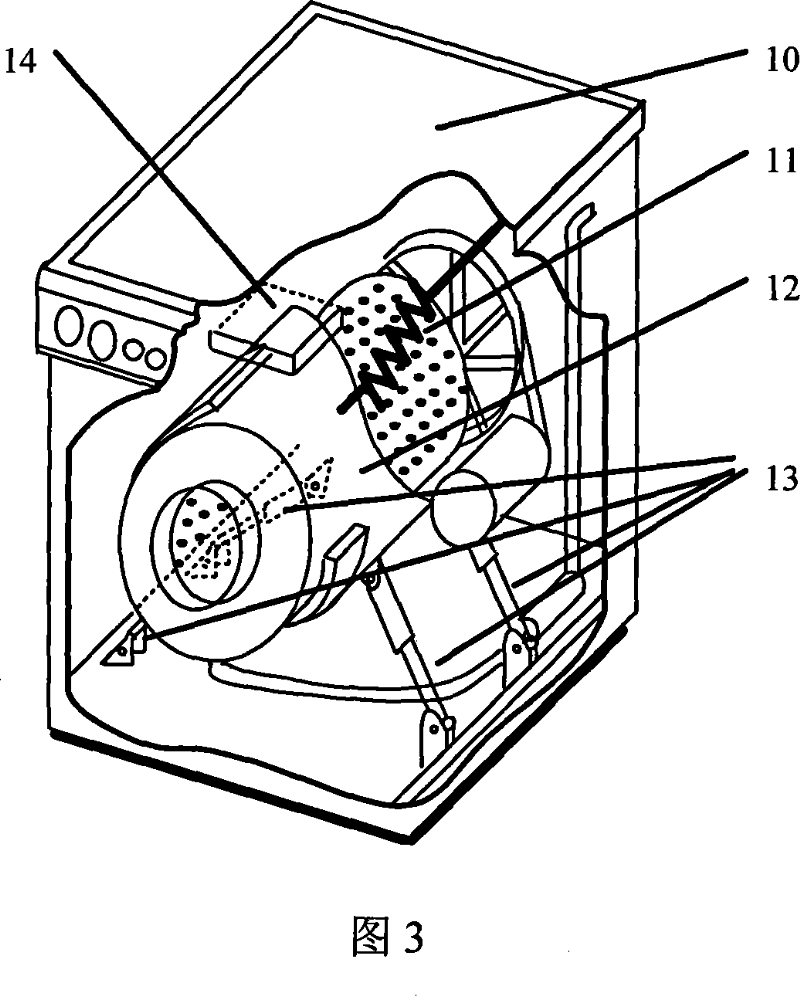

[0029] Embodiment 3 is a drum washing machine equipped with four magneto-rheological active shock absorbers. It is generally applied to a drum washing machine with a relatively large maximum load capacity of the washing machine. Four shock absorbers are installed under the washing tub, wherein the four magneto-rheological active shock absorbers in (a) are placed on the left and right sides of the washing tub respectively, facing each other two by two, forming two waists of an isosceles trapezoid. The four magneto-rheological active shock absorbers in (b) are crossed, and two of them are opposite to each other, forming two legs of an isosceles trapezoid.

[0030] In Fig. 5, the electronic control unit 22 changes the current 23 in the electromagnetic coil according to the vibration signal parameter 24 transmitted by the sensor unit 25, and then controls the intensity of the electromagnetic field around the electromagnetic coil 21, and the magnetic fluid 26 of the active shock ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com