Roof modified constitution of flat building and construction method

A technology for buildings and flat roofs, which is applied to building structures, building components, roofs, etc. It can solve problems such as poor construction, lack of vertical load, and endurance problems, and achieve good waterproof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

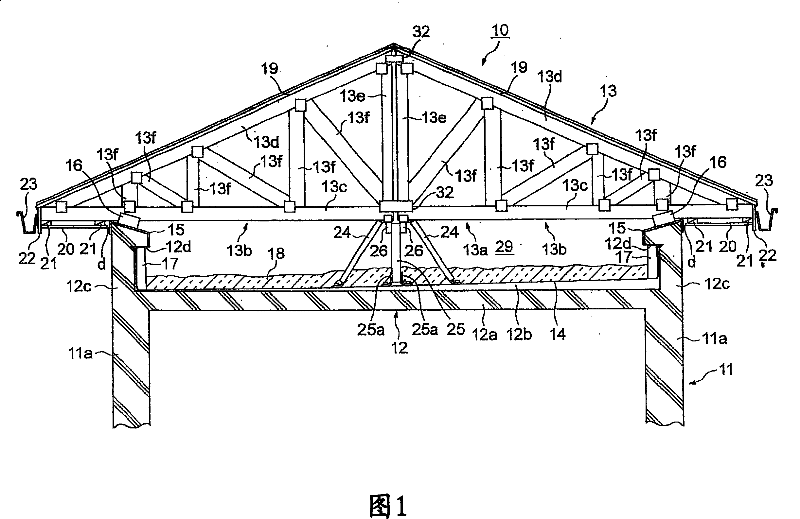

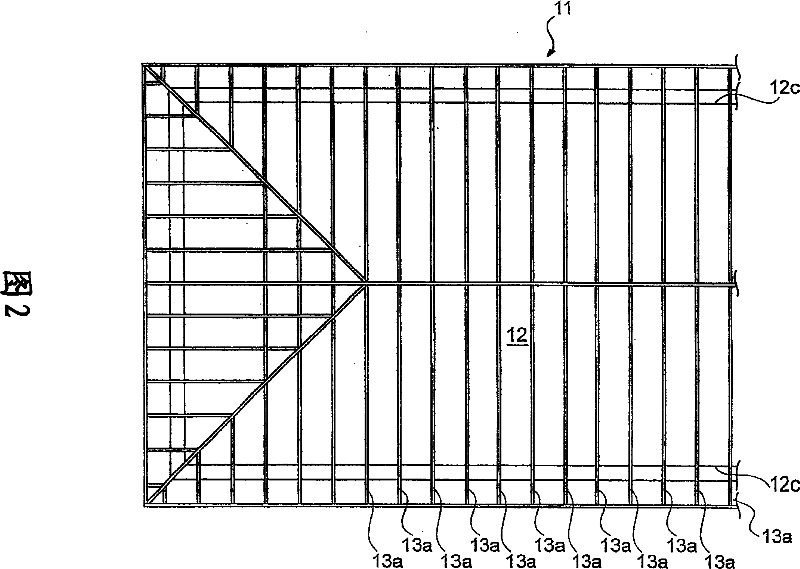

Embodiment 1

[0151] In the above-described embodiment, the new roof 13 is arranged on the flat roof 12 of the existing building 11 having the retaining wall portions 12c, 12c, but it is not limited thereto. As shown in FIG. The roof reconstruction structure 100 in which the new roof 13 is placed on the flat roof 120 of the existing building 110 formed with the eaves 120c, 120c.

[0152] In this roof reconstruction structure 100 , the eaves 120c, 120c extend horizontally from the outer walls 110a, 110a toward the outside at both edge portions of the flat roof 120 of the existing building 110 .

[0153] On the flat roof 120 of the existing building 110 having such a structure, the new roof 13 is arranged on the roof plate 120a surface of the flat roof 120 .

[0154] Moreover, the lower horizontal beams 13c, 13c of the partial truss structures 13b, 13b, which are the skeleton structure of the newly installed roof 13, are connected by the connecting member 160, ... Connect with flat top 120. ...

Embodiment 2

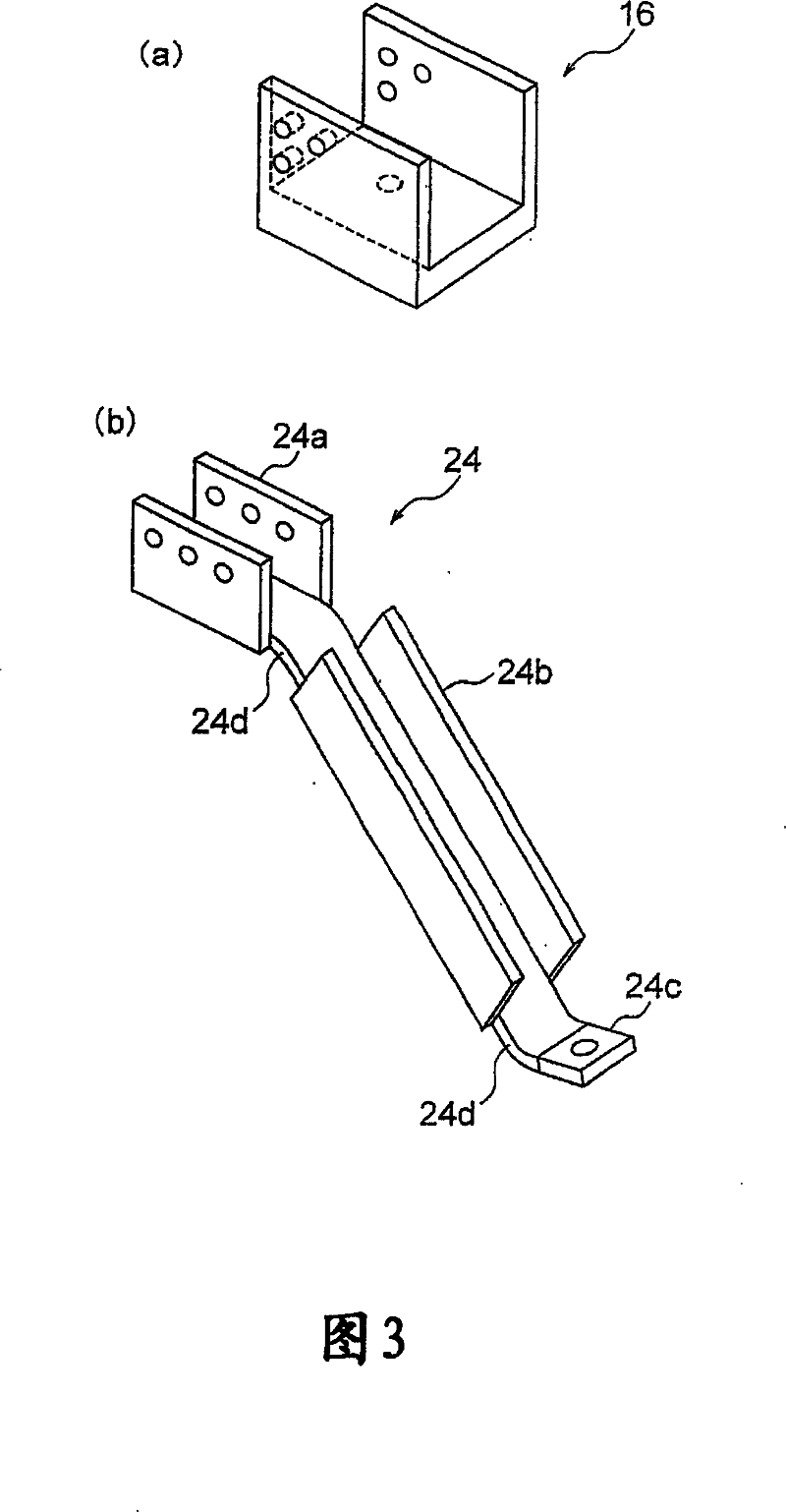

[0172] In the above-described embodiment, the parapet parts 12c, 12c of the flat roof 12 and the lower horizontal beams 13c, 13c of the new roof 13 are connected only by the parapet fittings 16, 16, but it is not limited thereto, as shown in FIG. 11 As shown, a roof reconstruction structure 200 may be provided in which a parapet fitting 224 as a connecting support member is installed between the newly installed roof 13 and the parapet portion 12c.

[0173] The shape of this parapet fitting 224 is substantially the same as that of the truss support fitting 24 of the above-mentioned embodiment, and is composed of an upper fixed end 224a, an inclined portion 224b, and a lower fixed end 224c.

[0174] The bottom surface of the upper fixed end 224a is fixed to the top surface of the protective wall portion 12c with the waterproof layer 15 interposed therebetween.

[0175] Further, the plate-shaped side walls extending upward from both sides of the bottom surface of the upper fixed ...

Embodiment 3

[0179]The truss support fittings 24, 24 serving as inclined members in the above-mentioned embodiment respectively support part of the truss structures 13b, 13b, but as shown in FIG. Both 13c and 13c are substantially parabolic truss support fittings 324 .

[0180] The upper fixed end 324a of the truss support fitting 324 is fixed so as to straddle the respective inner edge portions in the longitudinal direction of the lower horizontal beams 13c, 13c.

[0181] Therefore, since the lower horizontal beams 13c, 13c are connected to each other by the upper fixed end 324a, it is not necessary to separately use a connecting plate to connect the partial truss structures 13b, 13b to each other as in the above-mentioned embodiment, thereby improving the workability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com