Service Life predicting method and system for machine and vulnerable component of generating set

A technology for generator set and life prediction, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as economic loss, lack of methods and systems, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

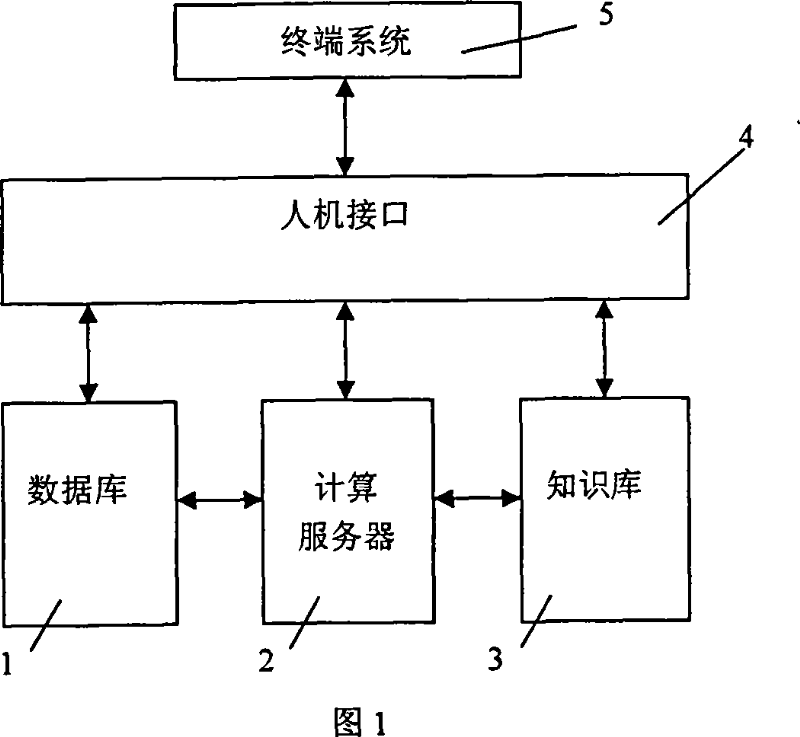

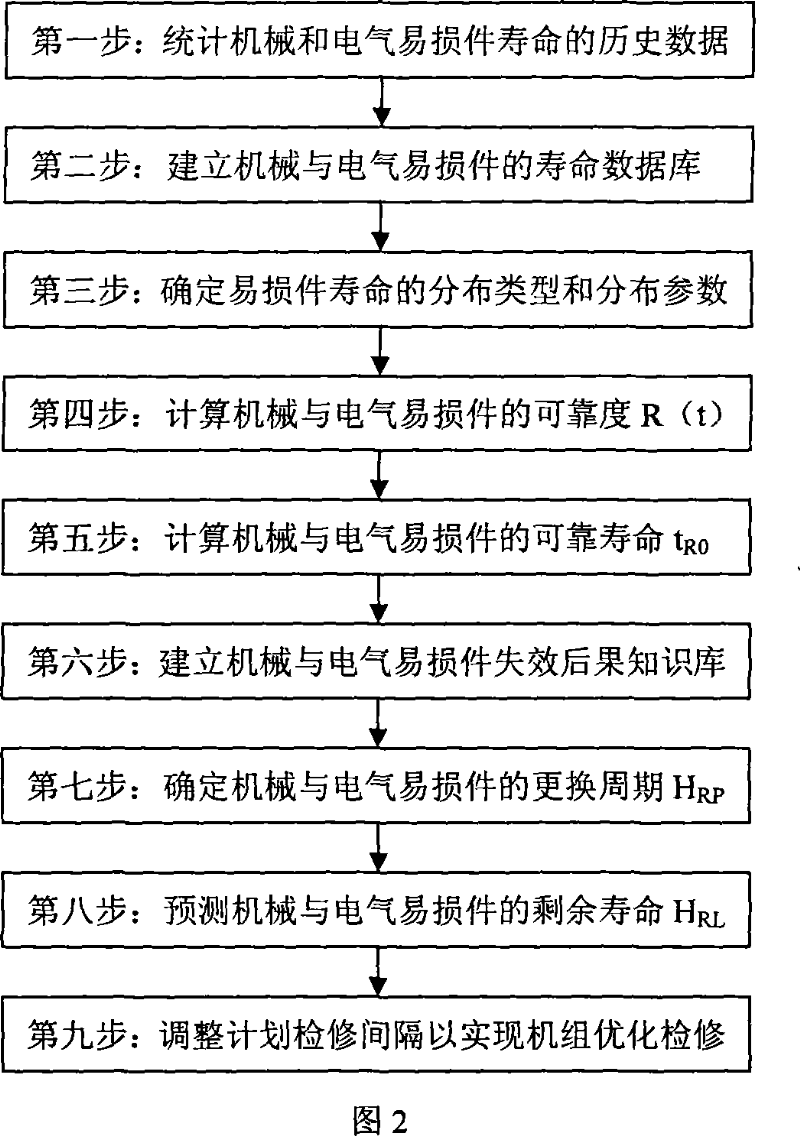

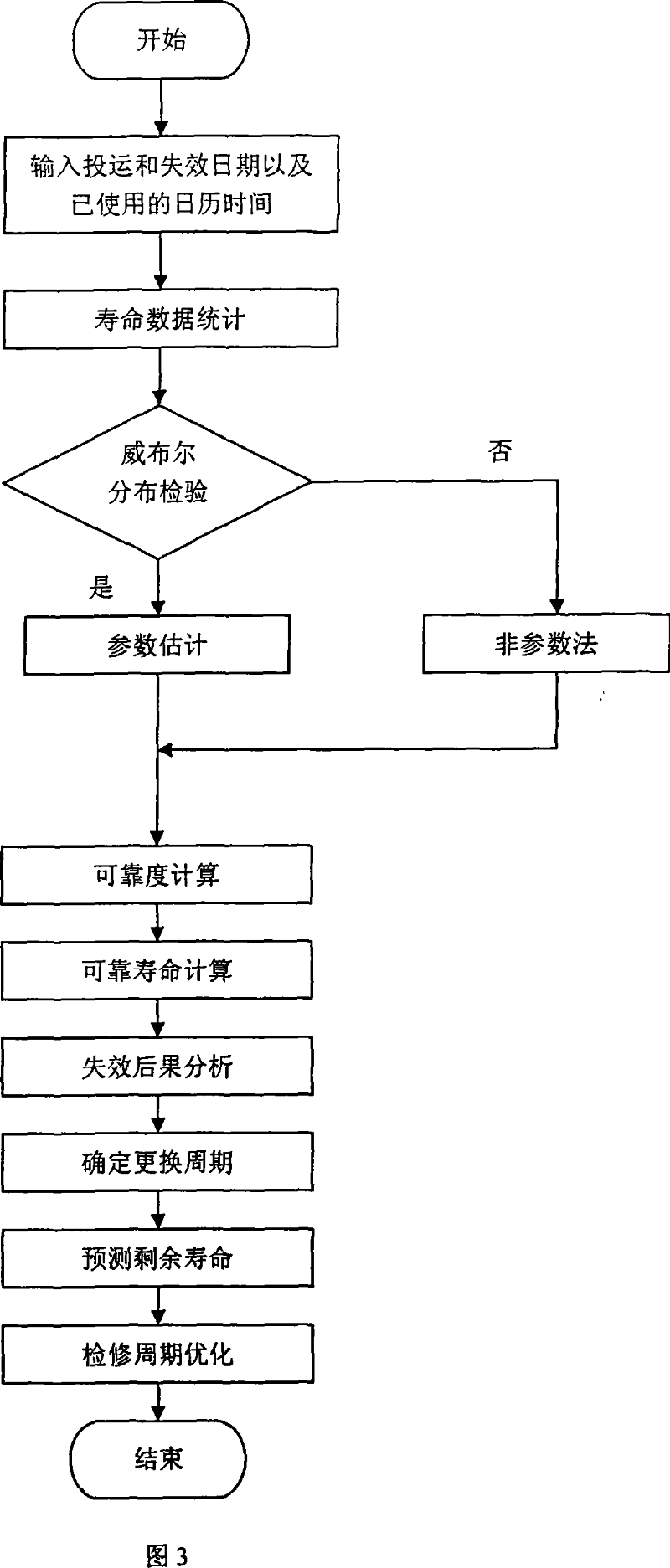

[0039] The burst tube failure of the power plant boiler superheater is one of the reasons for the unplanned outage of various types of thermal power units. The power plant boiler superheater tube is a mechanical vulnerable part of the thermal power unit. A certain type of 350MW power station boiler, the superheated steam pressure is 17.5MPa, and the superheated steam temperature is 540℃. Using the life prediction system of mechanical and electrical vulnerable parts of the generator set shown in Figure 1 and the computer software for life prediction of mechanical and electrical vulnerable parts of the generator set shown in Figure 3, the computer running in the control center of the mechanical equipment and electrical equipment of the power plant superior. For the life prediction of the primary superheater tubes of this type of power plant boiler, the flow chart of the life prediction of the mechanical and electrical wearing parts of the generator set shown in Figure 2 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com