Non-aqueous electrolyte battery

A non-aqueous electrolyte and battery technology, used in non-aqueous electrolyte storage batteries, electrolyte storage battery manufacturing, secondary batteries, etc., can solve problems such as large capacity deterioration, insufficient stability or cycle characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] [Preparation of non-aqueous electrolyte solution]

[0069] Mix ethylene carbonate (EC) and diethyl carbonate (DEC) at a volume ratio of 3:7, and dissolve lithium hexafluorophosphate (LiPF 6 ), to prepare a non-aqueous electrolyte.

[0070] [Production of diaphragm]

[0071] First, in acetone as a solvent, 5% by weight of inorganic particles TiO 2 [Rutile type structure, particle size 0.38μm, KR380 manufactured by Titanium Industry Co., Ltd.], relative to TiO 2 It is a copolymer (rubber-like polymer) containing 10% by weight of acrylonitrile structure (unit), and then mixed and dispersed using Filmics manufactured by a special machine to prepare TiO dispersed 2 of slurry. Next, the above-mentioned membrane was coated on both sides of a separator formed of a polyethylene (hereinafter abbreviated as PE) microporous membrane (thickness: 12 μm, porosity measured as described later: 38%) by dip coating method. The slurry is dried and the solvent of the slurry is removed ...

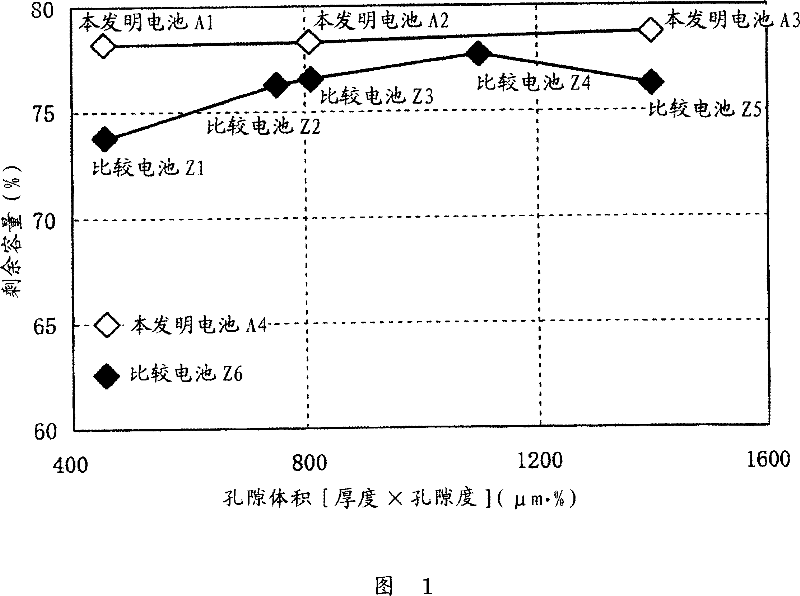

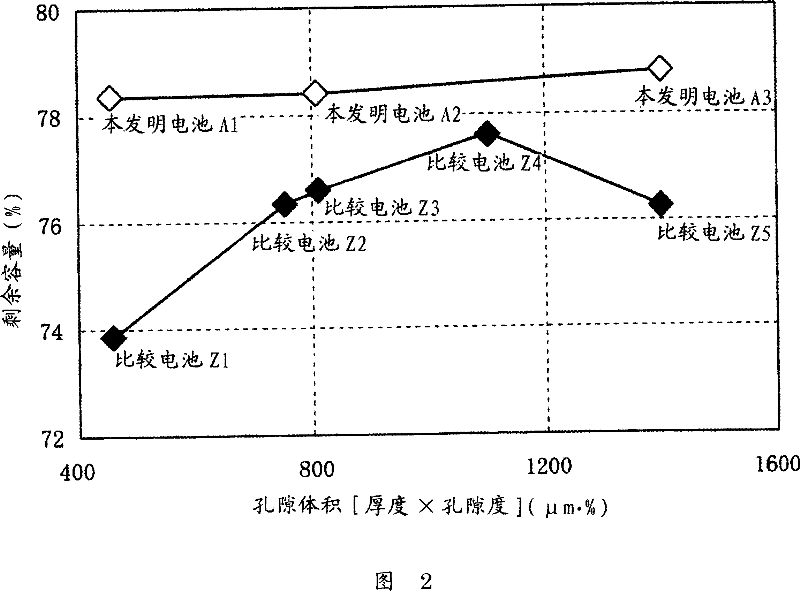

Embodiment 1

[0081] Example 1 uses the battery shown in the foregoing detailed description.

[0082] Hereinafter, the battery thus produced is referred to as battery A1 of the present invention.

Embodiment 2

[0084] A battery was fabricated in the same manner as in Example 1, except that a separator having a film thickness of 18 μm and a porosity of 45% [pore volume: 810 (μm·%)] was used.

[0085] Hereinafter, the battery thus produced is referred to as battery A2 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com